Method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage

A high-purity cathode copper and copper etching technology, applied in the field of environmental engineering, can solve problems such as factory troubles, high copper ion concentration, influence extraction and impurity entrainment, etc., to reduce investment costs and operating costs, reduce investment and operating costs, Reduces the effect of extraction entrained impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

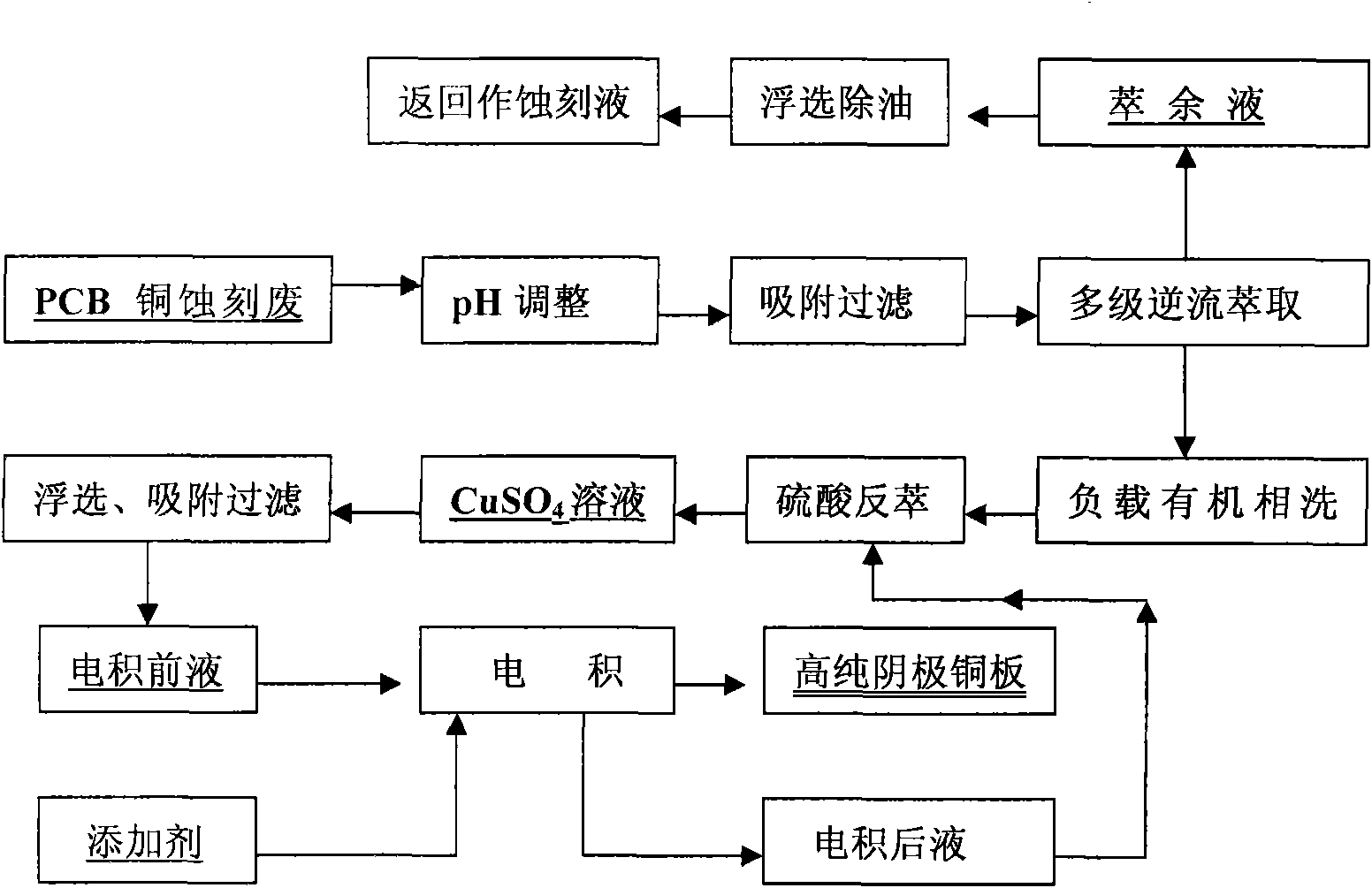

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: small test test

[0051] The acid chlorine-type copper etching solution wastewater is provided by Guangdong Meixian Qiaoyun Wastewater Treatment Plant. It is dark blue in appearance and thick, with a brown and black oil slick on it. After analysis, the copper content was 100.1g / L, the chloride ion content was 1033.3g / L, and the acidity was 1.5mol / L HCl. Take a certain amount of waste water for the following test after degreasing by flotation. The concentration of the prepared lix984 extractant is 25%. Get 25ml of oil-removing waste liquid, adjust the pH value to 2.5 with NaOH, absorb and filter the waste liquid, put it into a 500ml separating funnel, add the above-mentioned extractant, and extract, compared to O:W=4:1, manual Shake for 5 minutes, let stand for 7 minutes, and separate the phases. The raffinate is added with the above-mentioned new extractant to carry out the second extraction, and the method is the same as the first extraction. The chlo...

Embodiment 2

[0052] Embodiment 2: pilot test

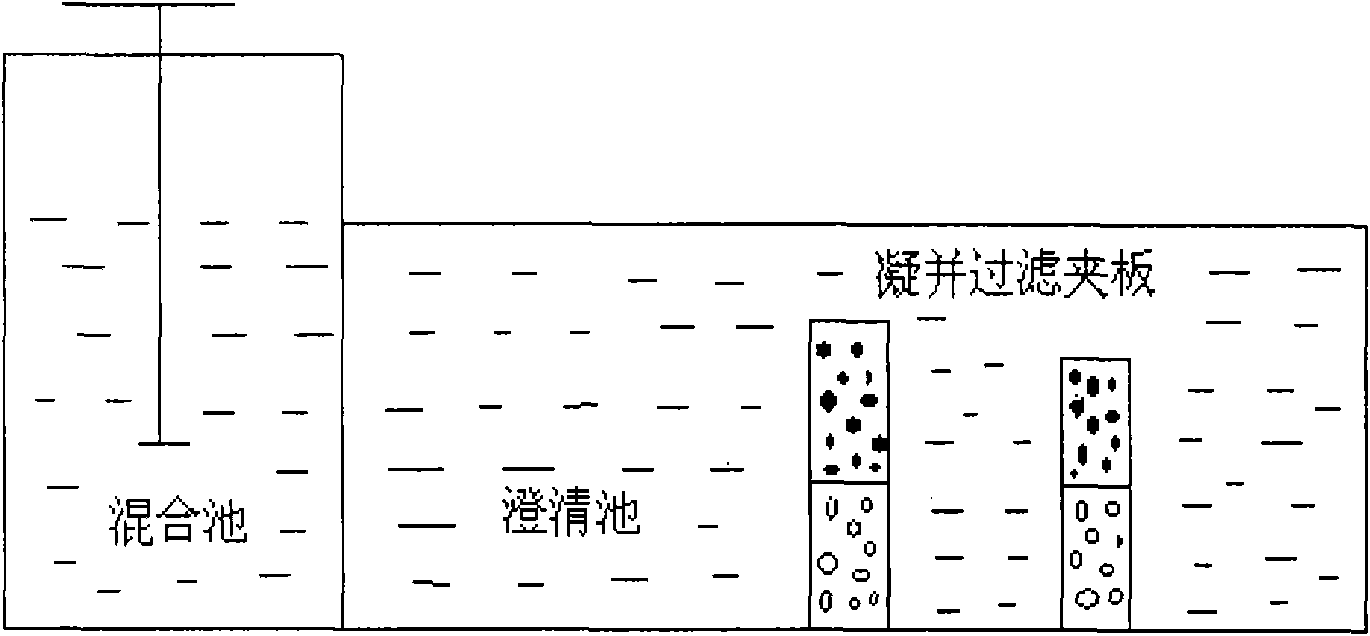

[0053] The source of waste liquid is the same as that of the small test. The test device is the bacterial leaching-extraction-electrowinning pilot laboratory of the key laboratory of the Ministry of Education of Biometallurgy. The second-stage countercurrent extraction is performed on the waste water that has been degreased by flotation and adjusted to a pH value of 2.5 with lime water. Condensation and baffles are two polypropylene perforated plates with a distance of 5 cm, and glass fiber and resin are filled between the two baffles. The waste water flow rate is 1L / h; the flow rate of lix984 extractant (concentration is still 25%) is 4L / h, the mixing time is 5min, the stirring speed is 150rpm, and the clarification time is 7min. By measuring and analyzing the copper content of the raffinate, the extraction recovery rate was calculated to be 95.7%. Wash twice with sulfuric acid at pH 2.5 in a ratio of 1:1. Then use 180g / L H 2 SO 4 Back-e...

Embodiment 3

[0055] The waste liquid comes from various acid etching liquid waste water collected by Guangdong Qiaoyun Wastewater Treatment Plant from various PCB factories. The waste water flows into the pH adjustment tank, and the lime water adjusts the pH to 2.0-2.5, with a flow rate of 3m 3 After the waste water of / h carries out flotation adsorption filtration to remove oil, carry out secondary countercurrent extraction operation; The flow rate of lix984 extraction agent (concentration is still 25%) is 12m 3 / h, the mixing time is 5min, the stirring speed is 150rpm, and the clarification time is 7min. The phase ratio is 1:1, and the two-phase flow ratio is 4:1. By measuring and analyzing the copper content of the raffinate, the extraction recovery rate was calculated to be 95.6%. Wash twice with sulfuric acid with a pH value of 2.0, and the phase and flow ratios are both 1:1. Then use 180g / LH 2 SO 4 Back-extraction, the ratio is 2.5:1, the copper sulfate solution obtained after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com