Double-swirl dual-fuel nozzle used for chemical regenerative cycle

A technology of chemical reheating cycle and double swirl flow, which is applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of deteriorating working environment of gas turbine blades, poor uniformity of outlet temperature field, and poor mixing effect, etc. , to achieve the effect of avoiding flameout, increasing turbulence intensity, and increasing swirl degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

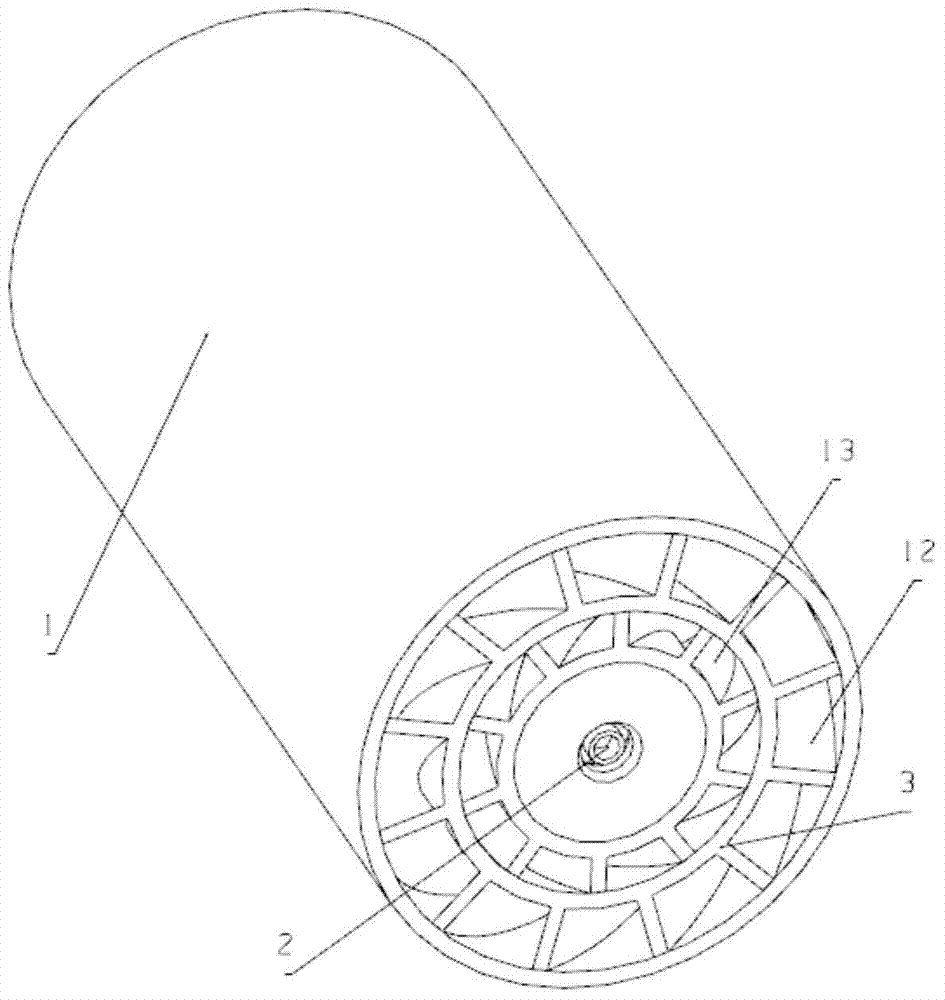

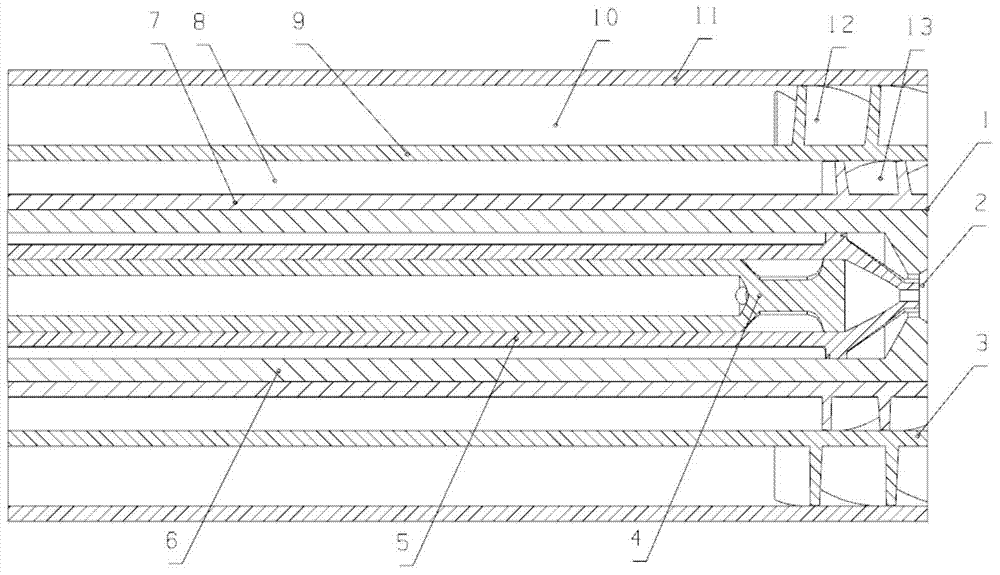

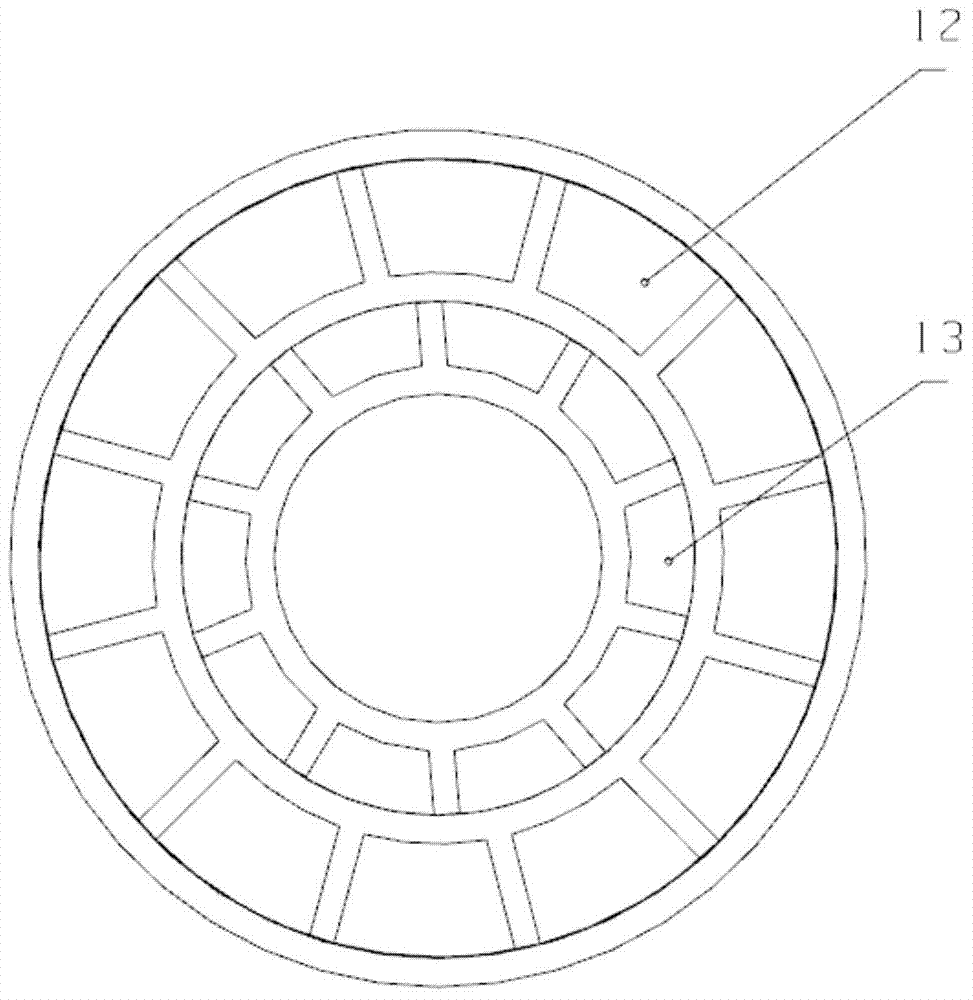

[0017] combine Figure 1~4 , the purpose of the present invention is to propose a dual-swirl dual-fuel nozzle for chemical reheating cycle, which increases the swirl degree of gas fuel through two-stage reverse swirl blades, strengthens the mixing of gas fuel and air, and strengthens the chemical Combustion in the combustion chamber in the regenerative cycle achieves the purpose of burning more fuel in a smaller space and shortening the length of the flame without causing ablation to the wall of the flame tube. At the same time, it can provide water vapor radial injection technology to ensure that the steam can be well mixed with air during reinjection, forming a humid air environment, so as to achieve the purpose of not extinguishing the fuel combustion and reducing emissions.

[0018] The dual-swirl dual-fuel nozzle 1 designed for the chemical reheating cycle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com