Reactor for catalytically oxidizing wastewater through ozone and application method thereof

An ozone catalytic oxidation and reactor technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve problems such as affecting ozone and restricting the development of ozone catalytic oxidation technology, reducing equipment investment, The effect of improving the utilization rate of ozone and strengthening the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

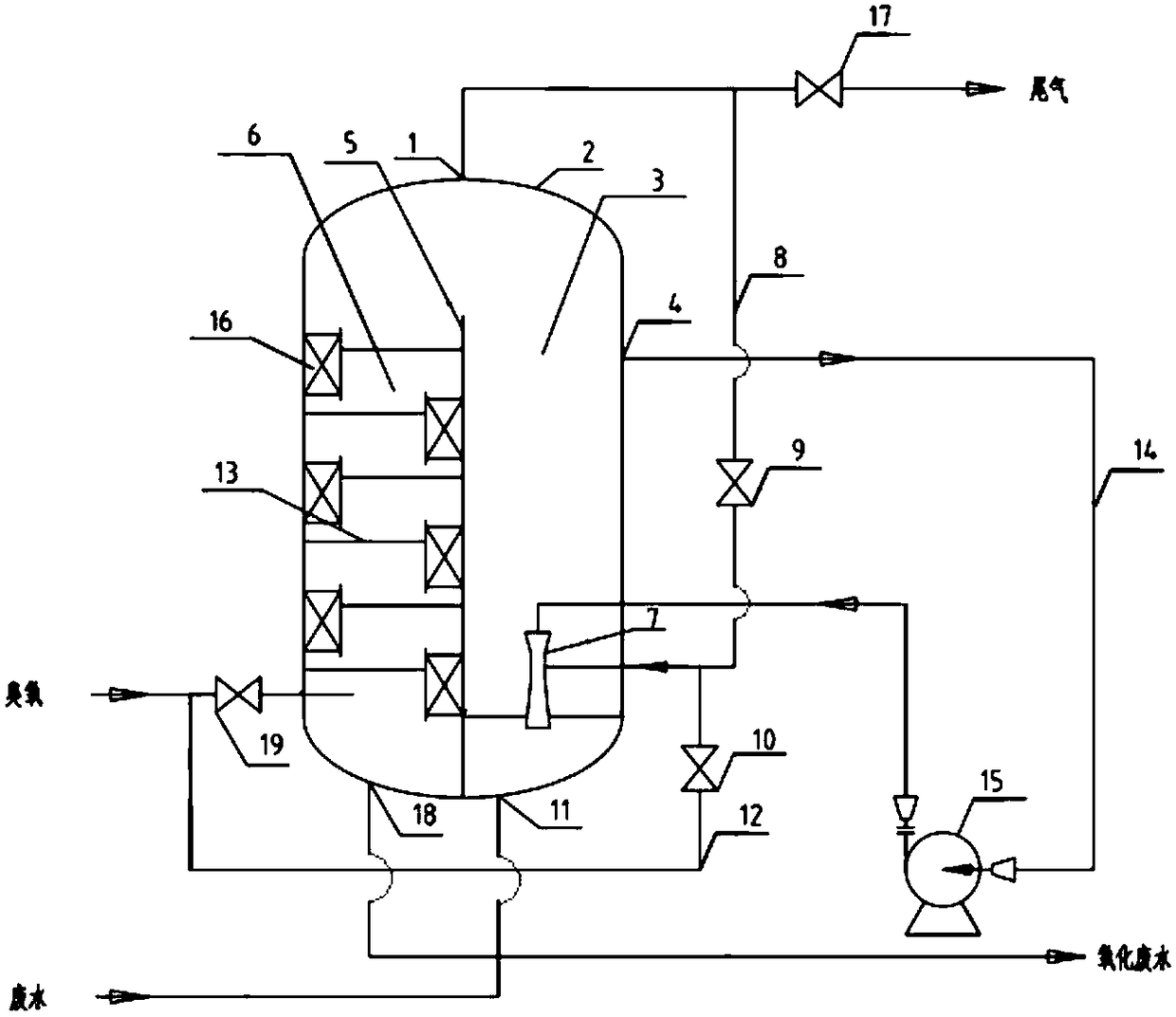

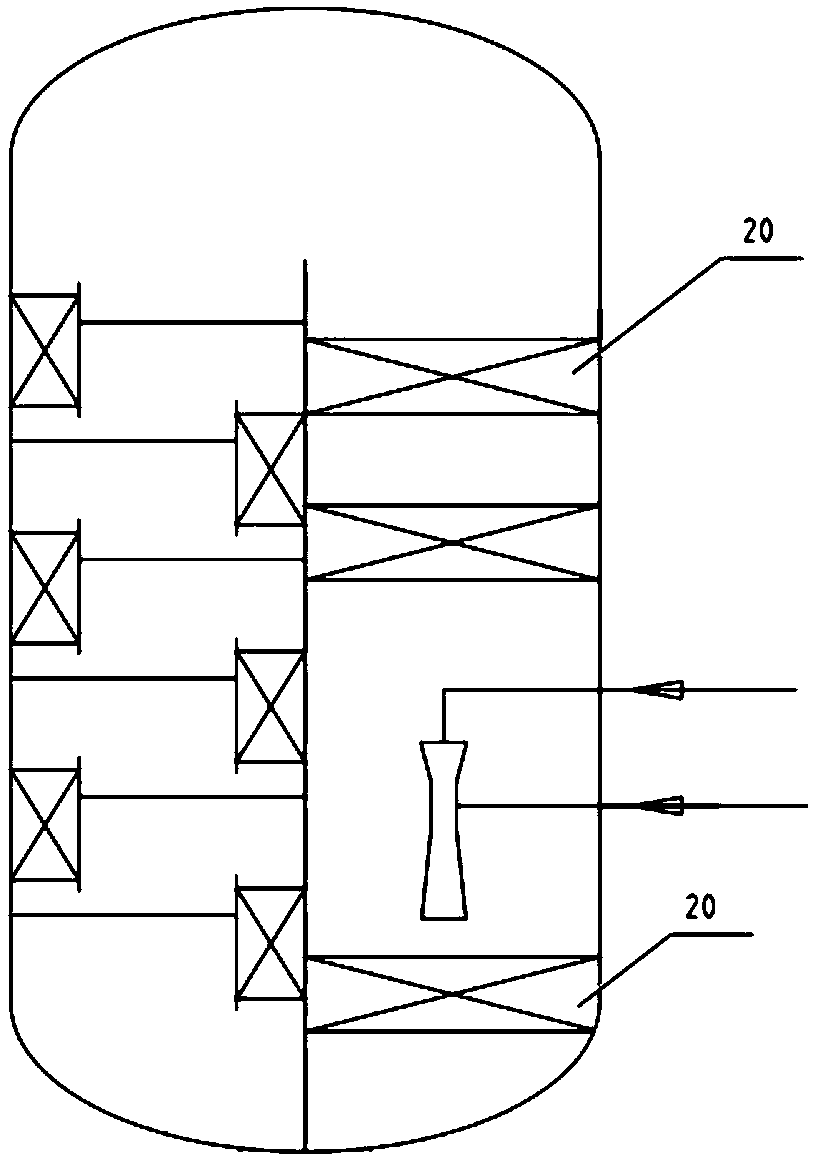

[0049] The above-mentioned reactor is used to carry out the ozone catalytic oxidation reaction of wastewater. The wastewater enters the bottom of the jet reaction chamber from the water inlet, flows upward, flows into the working fluid inlet of the injector through the water circulation outlet and the water circulation pipe, and flows into the working fluid inlet from the air inlet. After the ozone is mixed, a gas-liquid mixture is formed and sprayed downward. The gas-liquid mixture passes through the catalytic reaction of the first catalytic bed, overflows upwards and crosses the top of the partition, enters the tower reaction chamber, and passes through the tray and the second catalytic bed. While flowing downward, it further mixes and reacts with the ozone from the bottom of the tower reaction chamber, preferably flowing out through the water outlet at the bottom of the tower reaction chamber; the unreacted gas is returned from the gas outlet at the top of the reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com