Vapor chamber structure with improved wick and method for manufacturing the same

a vapor chamber and wick technology, applied in the direction of basic electric elements, lighting and heating apparatus, semiconductor devices, etc., can solve the problems of limited overall thermal performance of the vapor chamber, insufficient conductive heat transfer through solid materials, and a major obstacle to cooling or heat removal, etc., to achieve the effect of improving thermal performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

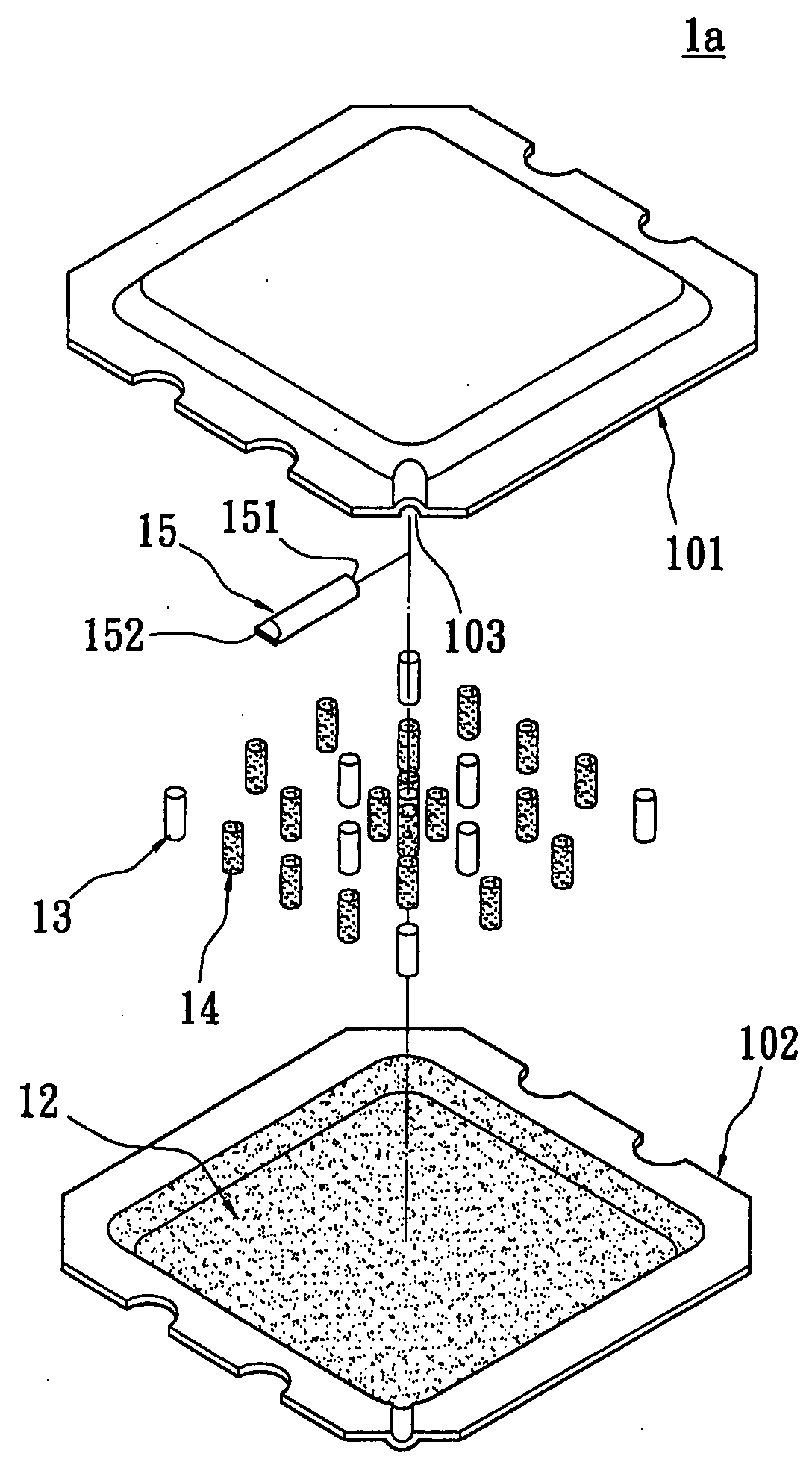

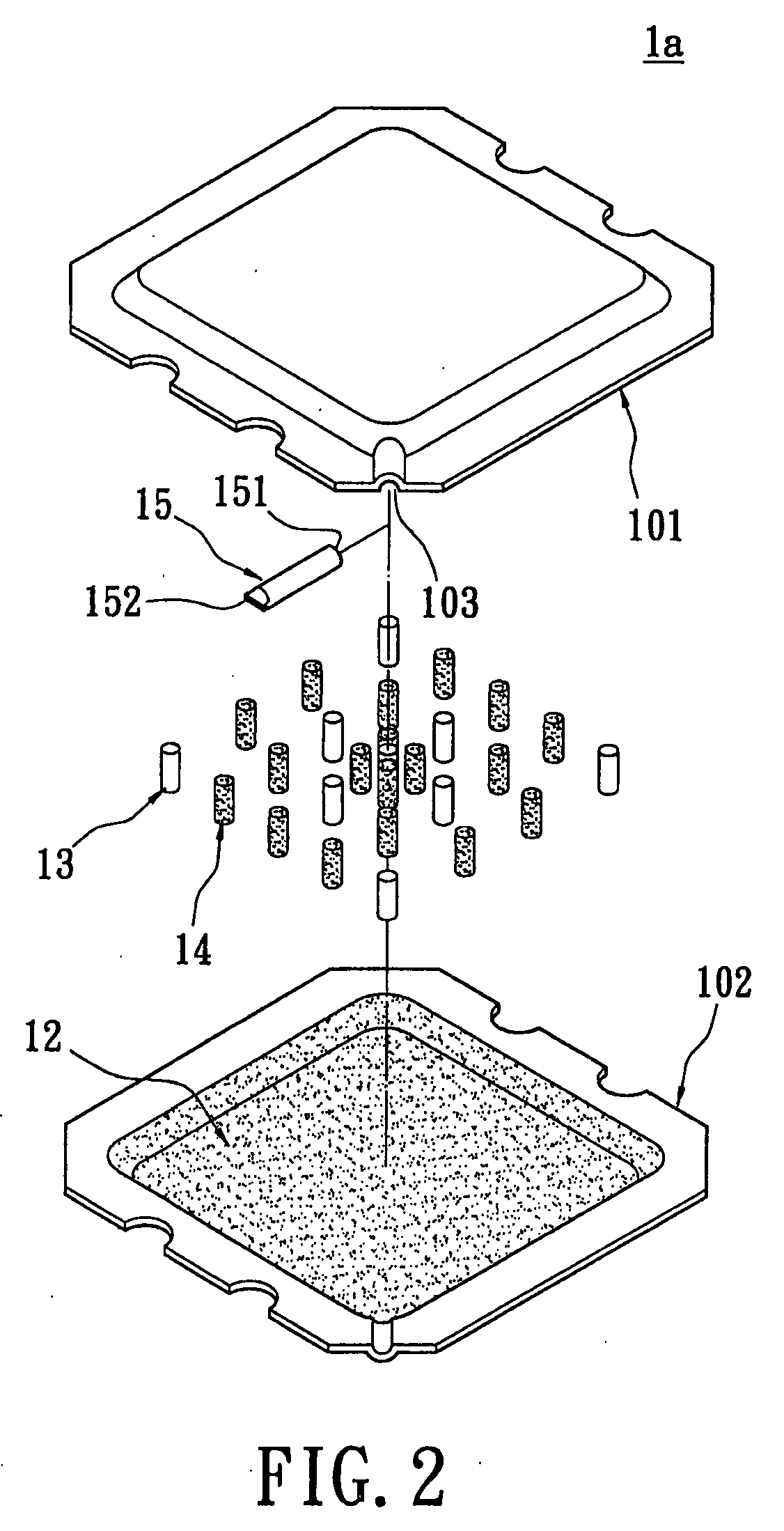

[0078]Referring to FIGS. 2 to 5, the first embodiment of the present invention provides a vapor chamber structure 1a, comprising: a casing 10, a working fluid 20, a wick layer 12, and at least one structure strengthening bodies 13.

[0079]The casing 10 has an airtight vacuum chamber 100, and the working fluid 20 is filled into the airtight vacuum chamber 100. The casing 10 is composed of an upper casing 101 and a lower casing 102 that mates with the upper casing 101. Moreover, the casing 10 has contact surfaces between the upper casing 101 and the lower casing 102. The contact surfaces have a predetermined width, in order to assemble the upper casing 101 and the lower casing 102 easily.

[0080]Furthermore, the vapor chamber structure further comprises at least one filling pipe 15 communicated with the airtight vacuum chamber 100 via a joint opening 103 of the casing 10 (in FIG. 2, a filling pipe 15 is shown). The filling pipe 15 has an opening side 151 formed on one side thereof and a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com