Method for real-time monitoring and transmitting hydraulic fracture seismic events to surface using the pilot hole of the treatment well as the monitoring well

一种水力压裂、观测井的技术,应用在用于测井记录的地震学、井眼/井部件、土方钻采等方向,能够解决总压力量限制、妨碍此类操作等问题,达到降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

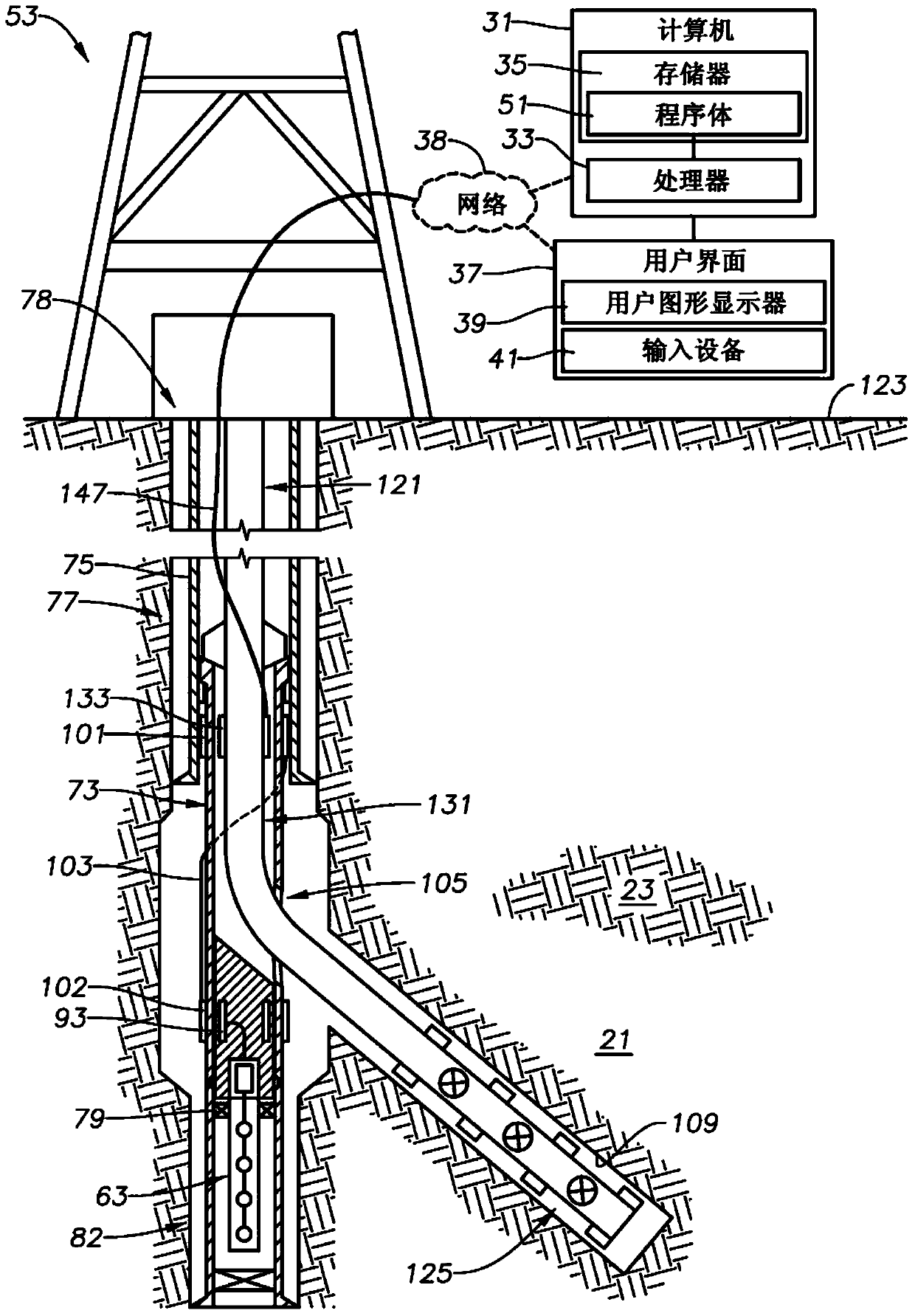

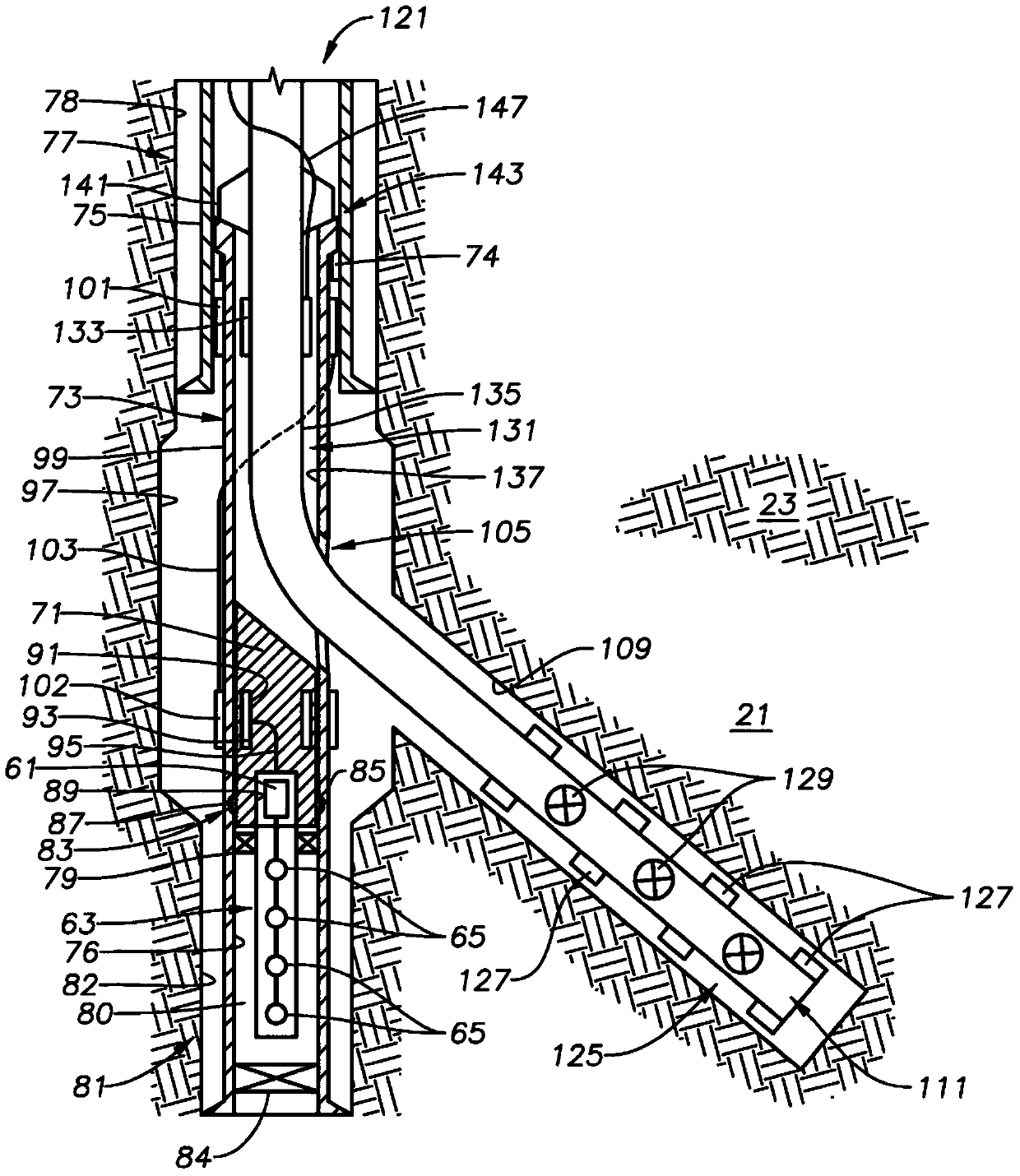

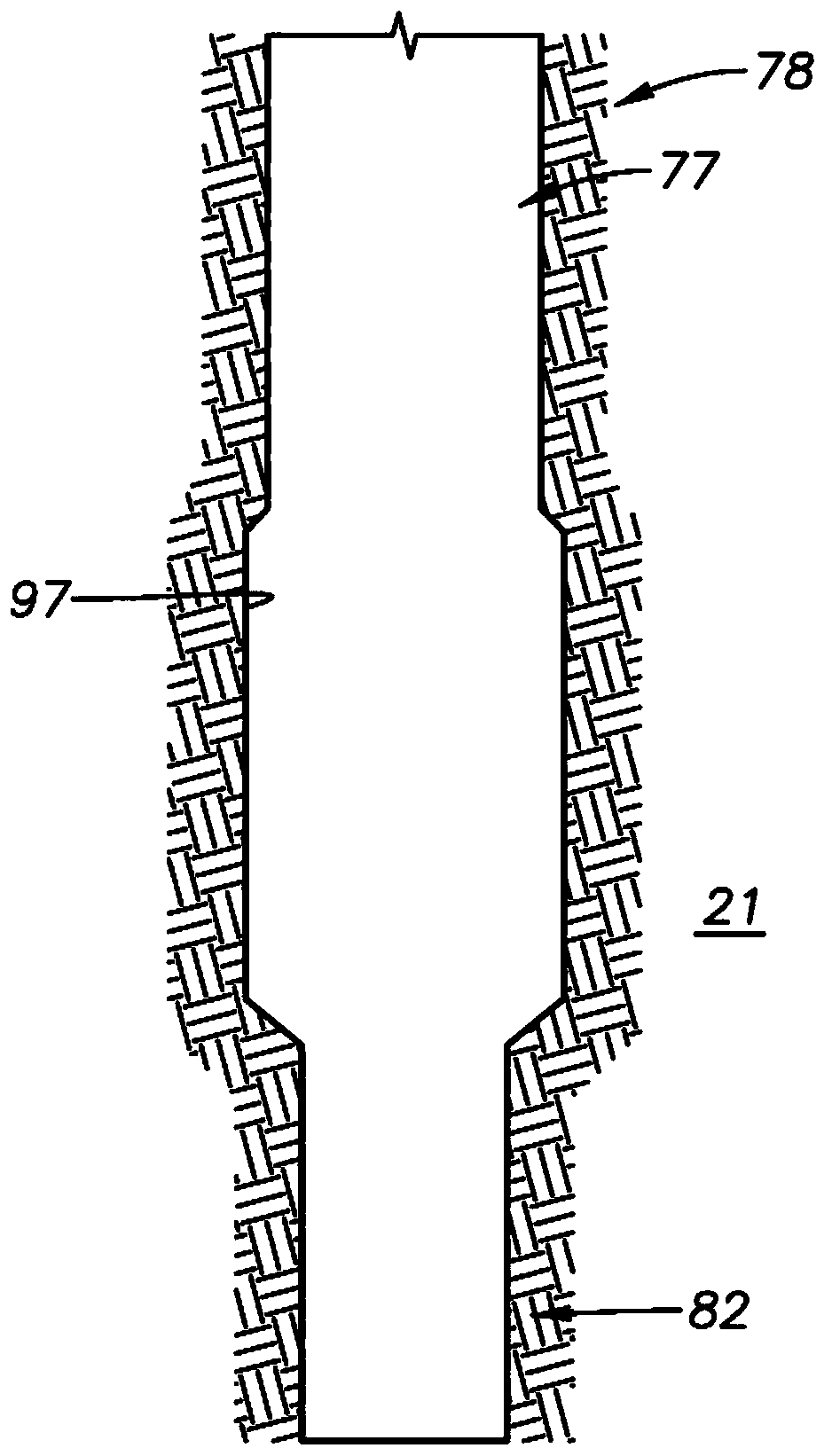

[0047] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings that illustrate various embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete and will fully convey the scope of the invention to those skilled in the art. Like reference numerals refer to like elements throughout. Primes, if used, indicate similar elements in alternative embodiments.

[0048] Various embodiments of the present invention preferably provide systems and methods for real-time monitoring of hydraulic fractures using pilot holes of treatment wells. According to an exemplary embodiment of the present invention, a well is drilled through a desired formation where a fracturing treatment will occur. A kickover tool or other deflection tool is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com