Coal rock pressure-maintaining coring inner barrel

A technology for coring and coal rock, which is used in the extraction of undisturbed core devices, earthwork drilling, etc., can solve the problems of core gas escape, long time for coring, affecting the measurement accuracy of coalbed methane content, etc., and achieve the effect of ensuring accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

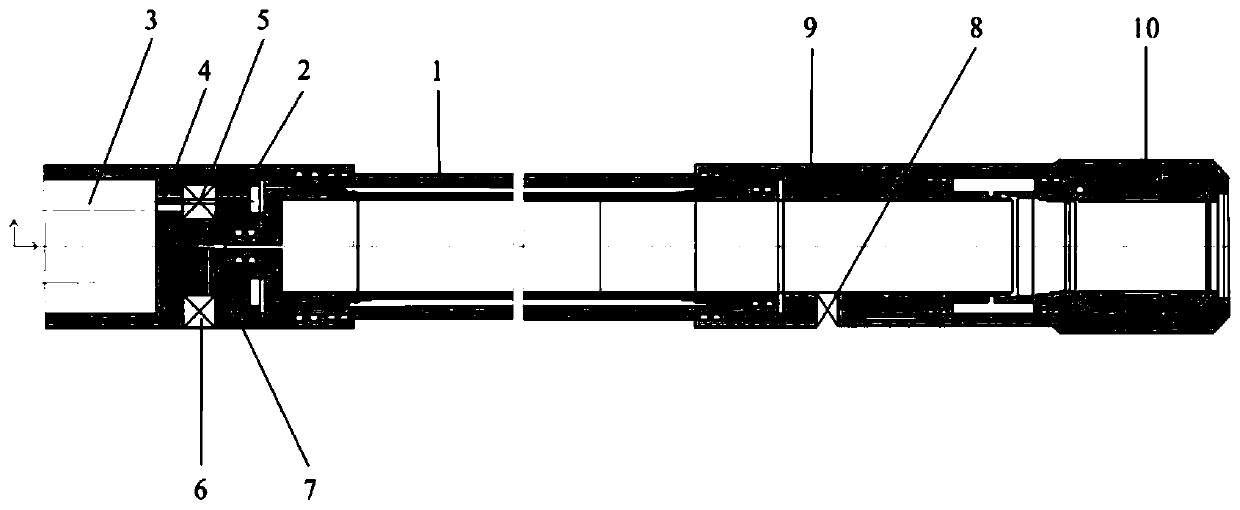

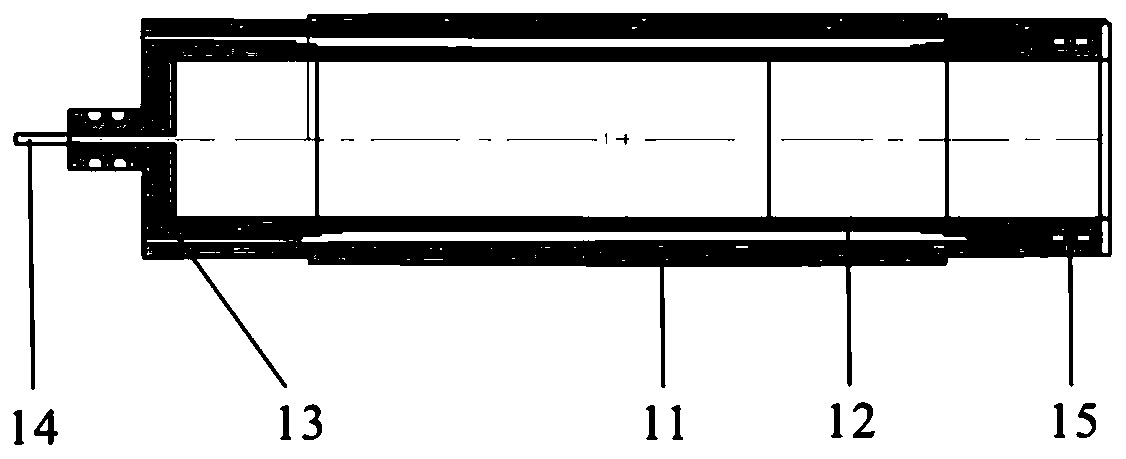

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The content and physical properties of coalbed methane under original formation conditions are important parameters for the formulation of coalbed methane exploration and development plans, which can be measured by drilling and coring. The coal rock coring device provided by the related art generally needs to extract the core out of the device and then test the coal rock bottom condition permeability. The process is cumbersome and affects the test accuracy. In this regard, the embodiment of the present invention provides a coal rock pressure-maintaining coring inner cylinder, which can be sealed immediately after coal rock underground coring, and the coal rock bottom condition permeability test can be performed without taking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com