Fire-drive oil-production ignition method for metamorphic rock burial hill high-cogulation oil pool

A technology for metamorphic rocks and buried hills, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of oil production without fire flooding and low porosity and permeability, and solve the problem of insufficient formation capacity and improve Increase oil production and solve the effect of lower formation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

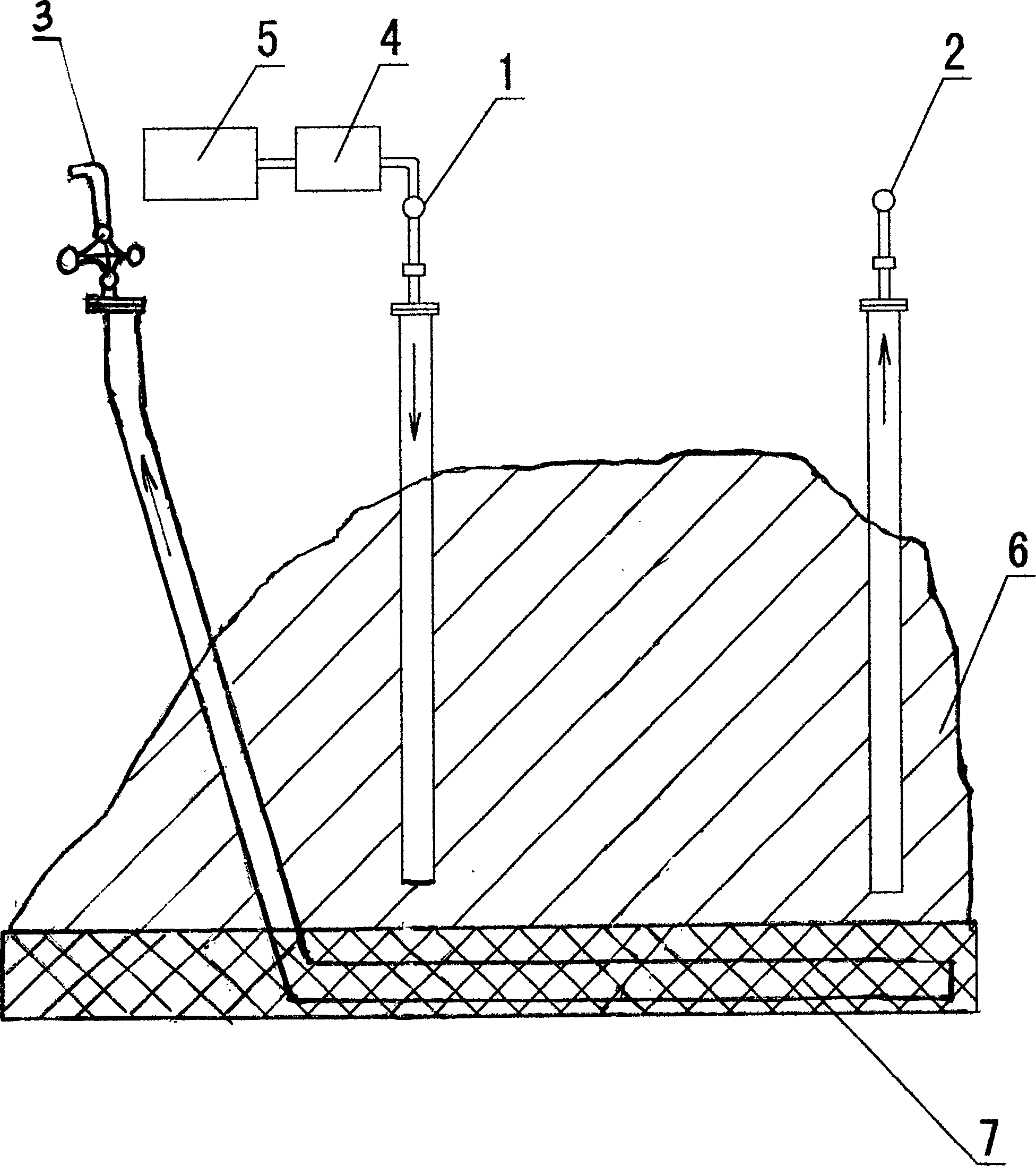

[0015] When the ignition well (injection well 1) is selected before the implementation of the present invention, the ignition layer should be selected at the position of the movable oil belt (the ground temperature is above 45° C.), and then the injection well 1 is used to implement artificial formation fracturing for the whole well. , implement artificial fractures on dense buried hill rock mass.

Embodiment 2

[0017] Injection well 1 and gas production well 2 should be designed to have a well depth 5-10 meters shallower than the horizontal section of horizontal production well 3. When igniting, hot air should be injected from injection well 1 so that the micro-cracked pores of buried hill formations can be filled with high pour point oil. When the temperature reaches 400°C, the high pour point oil in the fracture spontaneously ignites. At this time, the gas production well can discharge the air in the buried hill formation to support combustion. Since the crude oil in the formation burns at a low temperature, the viscosity of the surrounding high pour point oil decreases. , flows into horizontal production wells through formation fractures and is extracted from the ground.

Embodiment 3

[0019] After the oil layer is ignited, it is necessary to continuously observe the formation through ground instruments in time and measure the N2 / CO2 ratio. The N2 / CO2 ratio in the oil well is 9-12 for the best combustion state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com