High-intensity large-shrinkage sealed cambered-plate support structural element

A high-strength, closed-type technology, applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problem that the segment support structure cannot be directly applied, achieve fast construction speed, solve large surrounding rock pressure, and be reliable The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The preferred embodiment of the high-strength and large-shrinkage enclosed arc-plate support structure of the present invention is:

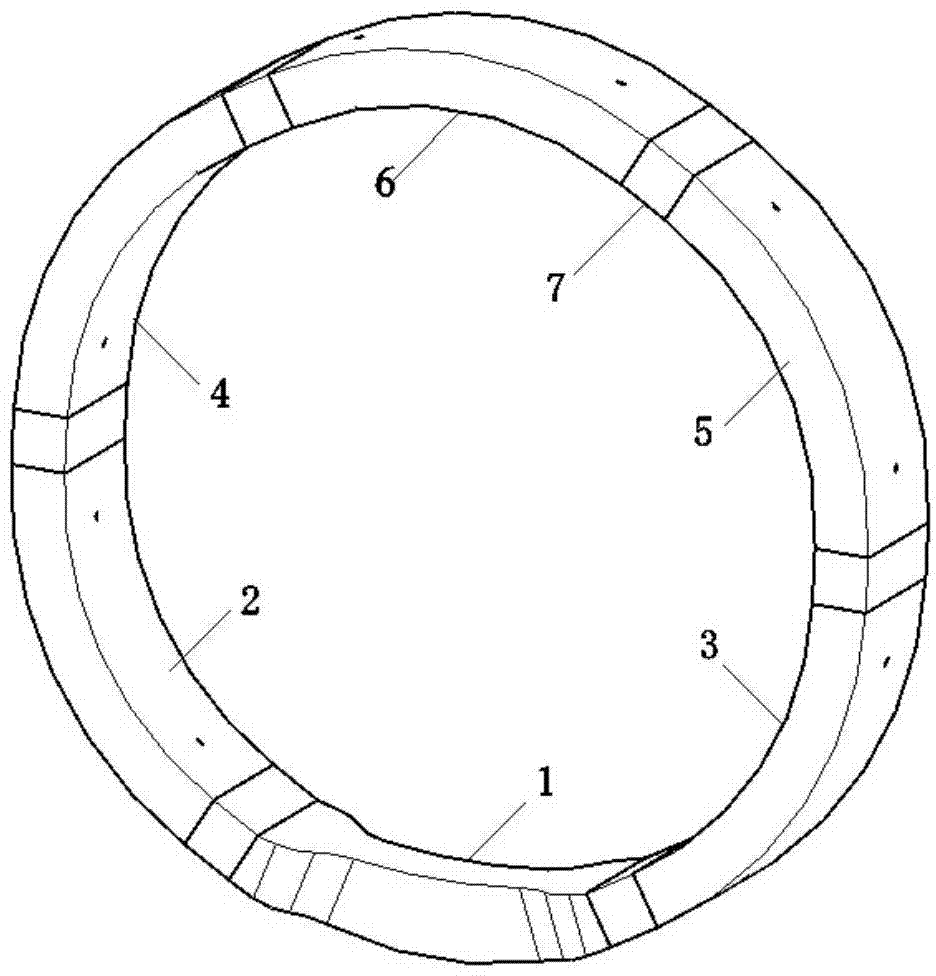

[0029] It consists of a circular structure surrounded by 4 to 8 reinforced concrete arc plates. There are pressure blocks between adjacent reinforced concrete arc plates, and corresponding pin holes are provided between the ends of adjacent reinforced concrete arc plates. and connecting steel pins, the connecting steel pins are inserted into the pin holes to connect two adjacent arc plates in series, the reinforced concrete arc plates are provided with pressure relief windows, and the pressure relief windows are set on the steel bars One or both sides of a concrete arc.

[0030] The reinforced concrete arc plate includes a bottom arc plate, a top arc plate, 2 left arc plates, and 2 right arc plates. After the pressure blocks are compressed by 50%, the circle formed by the reinforced concrete arc The structure is a standard circular struc...

specific Embodiment

[0047]Key structures include: prefabricated reinforced concrete arc slabs, yielding structures between reinforced concrete arc slabs (for example: compressible thick wood blocks, etc.), effective connections between reinforced concrete arc slabs (for example: using steel pin structures), etc. . The following are detailed descriptions respectively:

[0048] 1. Detailed structure of supporting structure

[0049] 1) The overall structure of the supporting structure

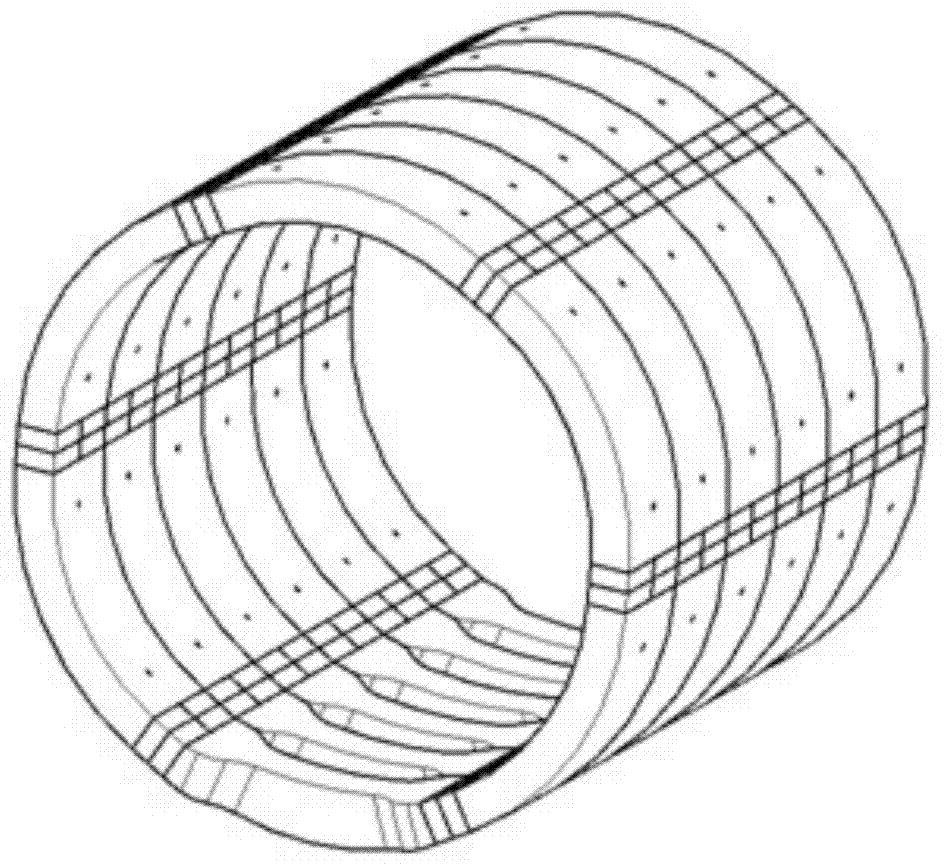

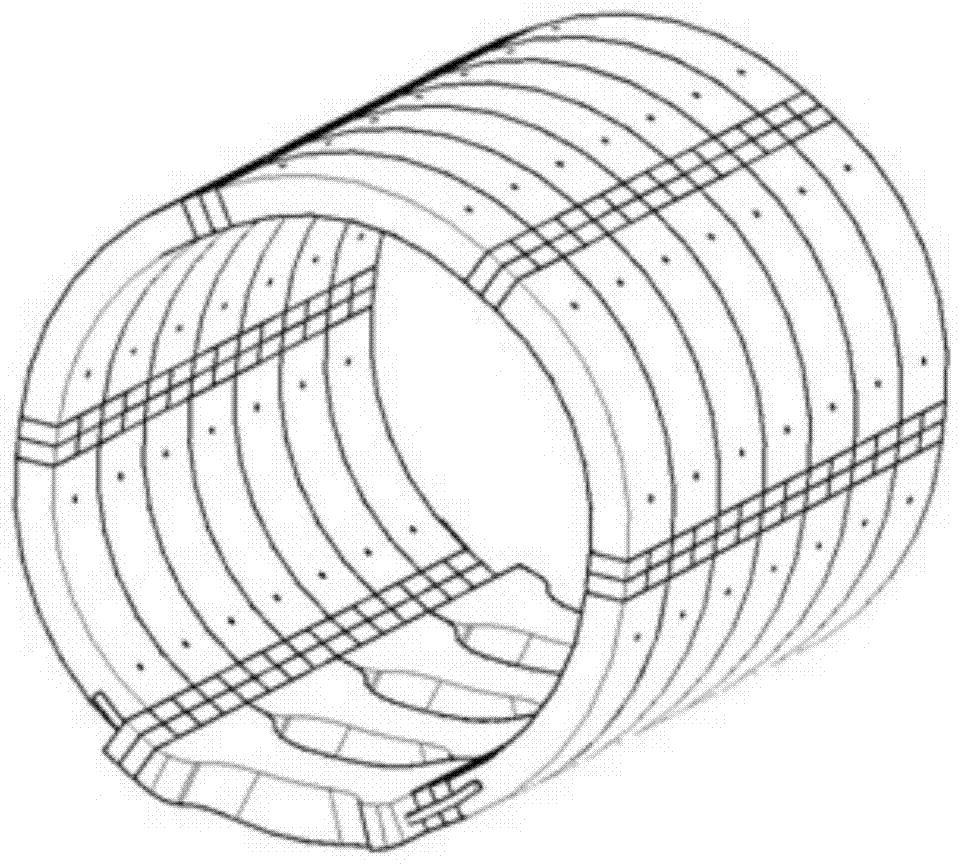

[0050] The support structure is generally composed of 6 arc plates, and pressure blocks are installed between adjacent arc plates. In order to ensure the overall stability of the support structure, the arc plates are connected together by "connecting steel pins". ,Such as Figure 1a , Figure 1b and figure 2 shown.

[0051] The large-shrinkage arc-plate support structure generally has a circular cross-section, the inner diameter of the roadway is generally 5m to 7m, the wall thickness of the arc plate is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com