Method for forming architectural materials by explosion

A technology of building materials and explosion impact, which is applied to the formation of building materials by explosion, and the field of building materials formed by explosive explosion impact in the formation, which can solve the problems of insufficient comprehensiveness, quality limitation, and insufficient depth, etc., and achieve low cost and large elasticity and plastic deformation ability, the effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

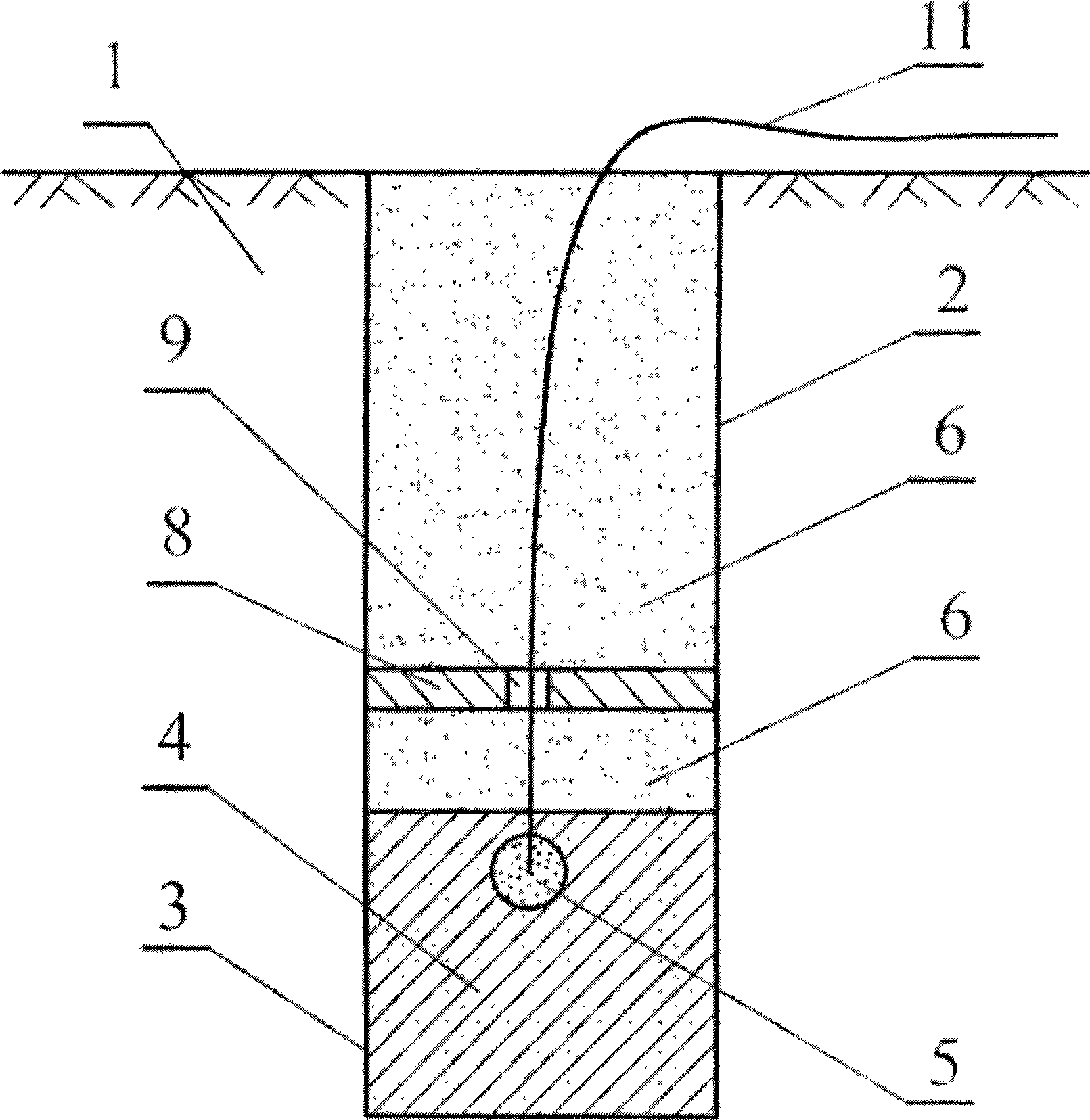

[0014] Firstly, choose a flat stratum (1), and the stratum (1) is preferably evenly distributed undisturbed soil. A vertical shaft with a circular cross-section is dug downward from the surface. The upper part of the shaft is used as a channel (2) for lowering explosives and materials, and the lower part is used as a storage bin (3). The material (4) is lowered into the silo (3) through the channel (2). Place the explosive charge (5) on top of the material (4). The upper part of the explosive charge (5) and the material (4) is uniformly covered with a plug (6) of suitable thickness. Place the mold (8) on the top of the sand material, and pass the hole (9) on the mold (8) through the detonating cord (11) of the detonating charge (5) simultaneously. Lead the detonating cord (11) to the surface. Continue to backfill the plug (6) into the channel (2). Index the explosive charge cartridge (5) through the detonation. After the material (4) is solidified, the formation (1) is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com