Colloid heat insulation protection structure as well as preparation method and application thereof

A technology of heat insulation protection and colloid, which is applied in the direction of blasting, etc., can solve the problems that it is difficult to meet the environmental temperature requirements of explosives, restrict the progress of stripping and excavation work, and cannot meet the high temperature blasting in fire areas, etc., and achieve good market application prospects. It is convenient for factory-scale production and the effect of sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

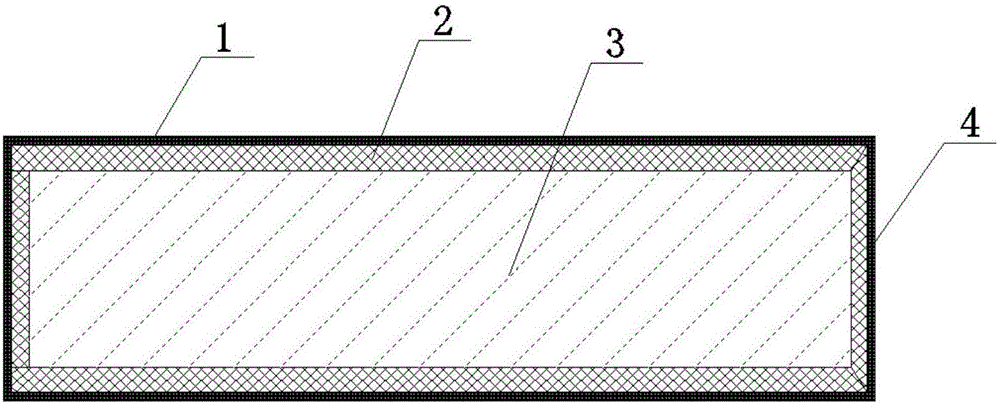

[0029] Such as figure 1 As shown, the colloidal heat insulation structure is 50cm long and 130mm in outer diameter, and the wrapping materials are in order from outside to inside: 1mm thick thin-walled stainless steel tube 1, 19mm thick colloid material 2, and 90mm outer diameter industrial explosive roll 3 , the top and the bottom are sealed 4, place the colloidal heat insulation protection structure on a 550°C flame and burn for 30 minutes, the initial temperature of the colloid layer is 18°C, then remove the flame and measure the drug with a thermocouple YC-727UD thermometer The temperature of the outer surface and center of the roll, the maximum temperature of the explosive body does not exceed 80°C, and the average temperature is about 75°C. The outer surface of the explosive is taken out without damage, and the explosion transmission experiment is carried out. Coal Mine Safety Standard Permission Requirements. The colloid heat insulation structure effectively prolongs t...

Embodiment 2

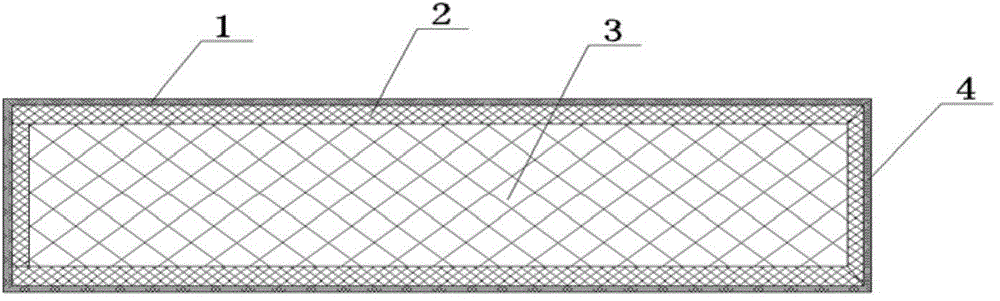

[0031] Such as figure 2As shown, the colloidal heat insulation structure is 40cm long and 60mm in outer diameter, and the wrapping materials are, in order from outside to inside, 2mm thick heat-resistant carbon fiber tube 1, 12mm thick colloid material 2, and 32mm outer diameter industrial explosive roll 3 , the top and the bottom are sealed 4. Place the colloidal heat insulation protection structure in a high temperature environment of 300 ° C for 45 minutes. The initial temperature of the colloid layer is 18 ° C. Measure the temperature of the outer surface and the center of the powder roll. The highest temperature of the powder body does not exceed 80°C, and the average temperature is about 70°C. The outer surface of the explosive is taken out without damage, and the explosion transmission experiment is carried out. It is known that the explosion of the explosive is reliable and meets the requirements of civil explosion Items and coal mine safety standards permitting requi...

Embodiment 3

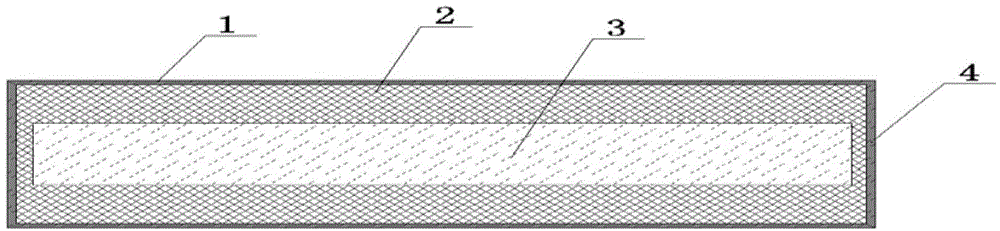

[0033] Such as image 3 As shown, the length of the colloidal heat insulation structure is 35cm, and the outer diameter is 38mm. The wrapping materials are in order from outside to inside: 0.2mm thick fireproof foil film 1, 15mm thick colloid material 2, and industrial detonating cord with 7mm outer diameter 3. The top and bottom are sealed. 4. Place the colloidal heat insulation protection structure in a high temperature environment of 250°C for 60 minutes. The initial temperature of the colloid layer is 18°C. Measuring the temperature of the outer surface and center of the charge roll, the maximum temperature of the charge body does not exceed 80°C, and the average temperature is about 73°C. The outer surface of the detonating cord is taken out without damage, and the detonation transmission experiment is carried out. It is known that the detonation cord is reliable in detonation transmission. , to meet the requirements of civil explosives and coal mine safety standards. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com