Powdery modified ammonium nitrate fuel oil for coal mine

A ammonium oil explosive and modification technology, which is applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as TNT pollution, achieve the effect of no reduction in explosive performance, increase of contact area, and long-term pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The formula of Example 1 is: (mass percentage) ammonium nitrate 76.5, modified wood flour 5, special oil phase 3.0, industrial salt 15, modifier 0.5.

Embodiment 2

[0037] The formula of Example 2 is: (mass percentage) ammonium pinate 72.5, modified wood powder 4.5, special oil phase 2.5, industrial salt 20, modifier 0.5.

Embodiment 3

[0038] The formula of Example 3 is: (mass percentage) ammonium nitrate 70.7, modified wood powder 5, special oil phase 3, water-resistant agent 0.8, industrial salt 20, modifier 0.5.

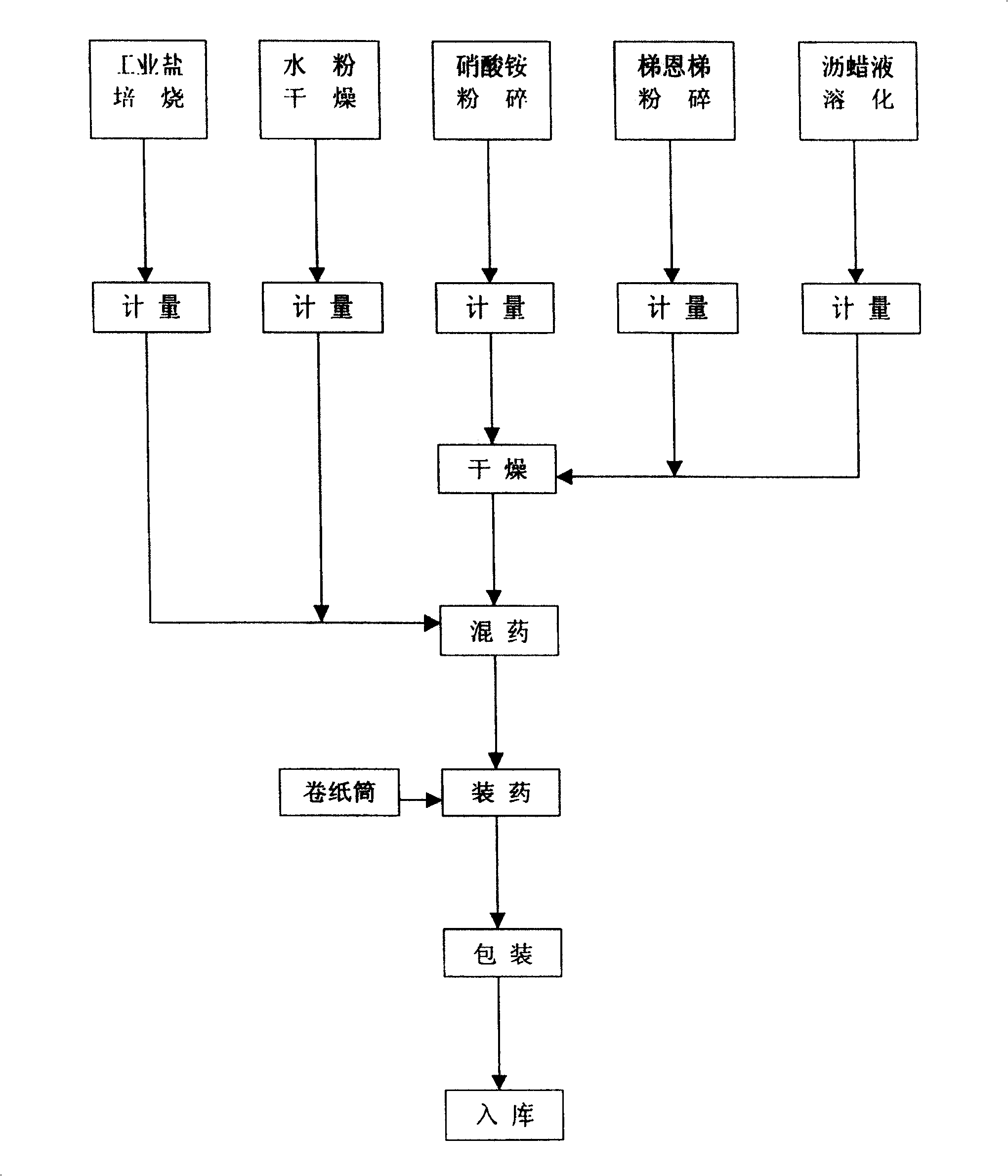

[0039]When one-stage production is adopted, the production process is as follows:

[0040] Ammonium nitrate pulverized metering, water repellant,

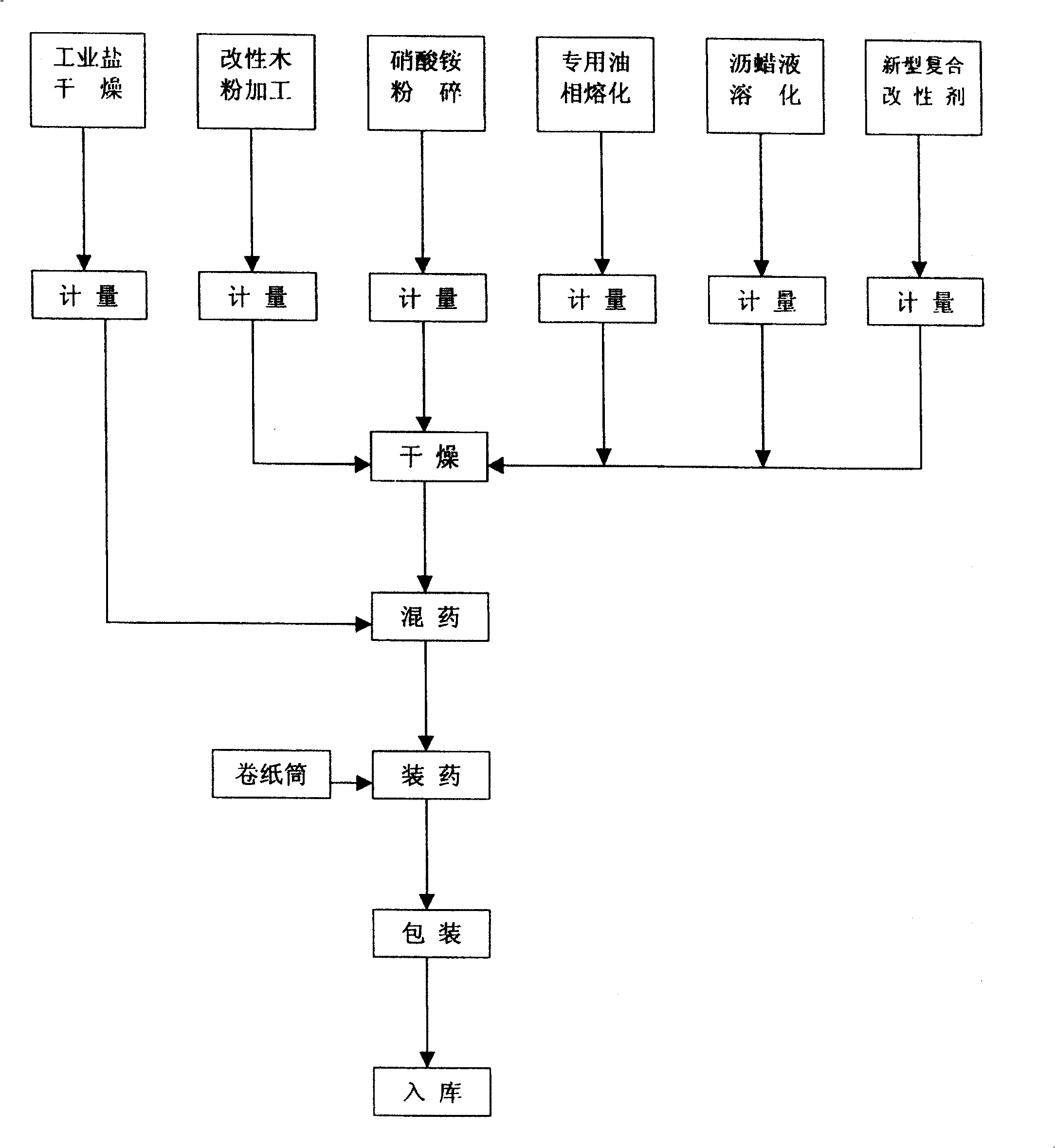

[0041] When using the two-stage method for production, the production process is as follows:

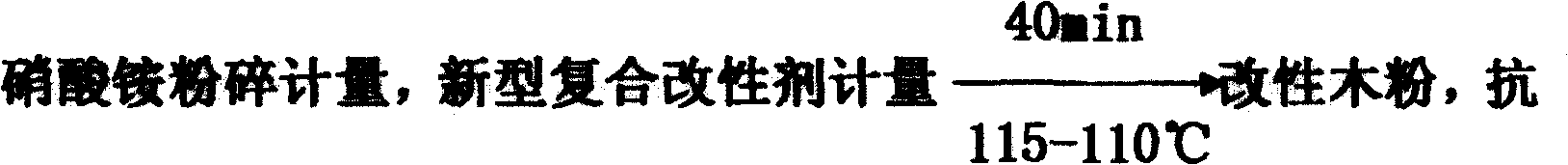

[0042] (1) High temperature heavy weight drying ammonium nitrate

[0043]

[0044] (2) Low temperature and medium weight mixed medicine

[0045]

[0046] The specific differences between the production process of powdered modified ammonium oil explosives allowed in coal mines and the production process of ammonium ladder explosives allowed in coal mines are as follows:

[0047] 1. Adjust the drying temperature and drying time.

[0048] 2. Adjusted the feeding order.

[0049] 3. Drying time and feeding sequence are the key factors affectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com