Small temperature-rise low-entropy mixing combustion engine

An engine, piston engine technology, used in combustion engines, internal combustion piston engines, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

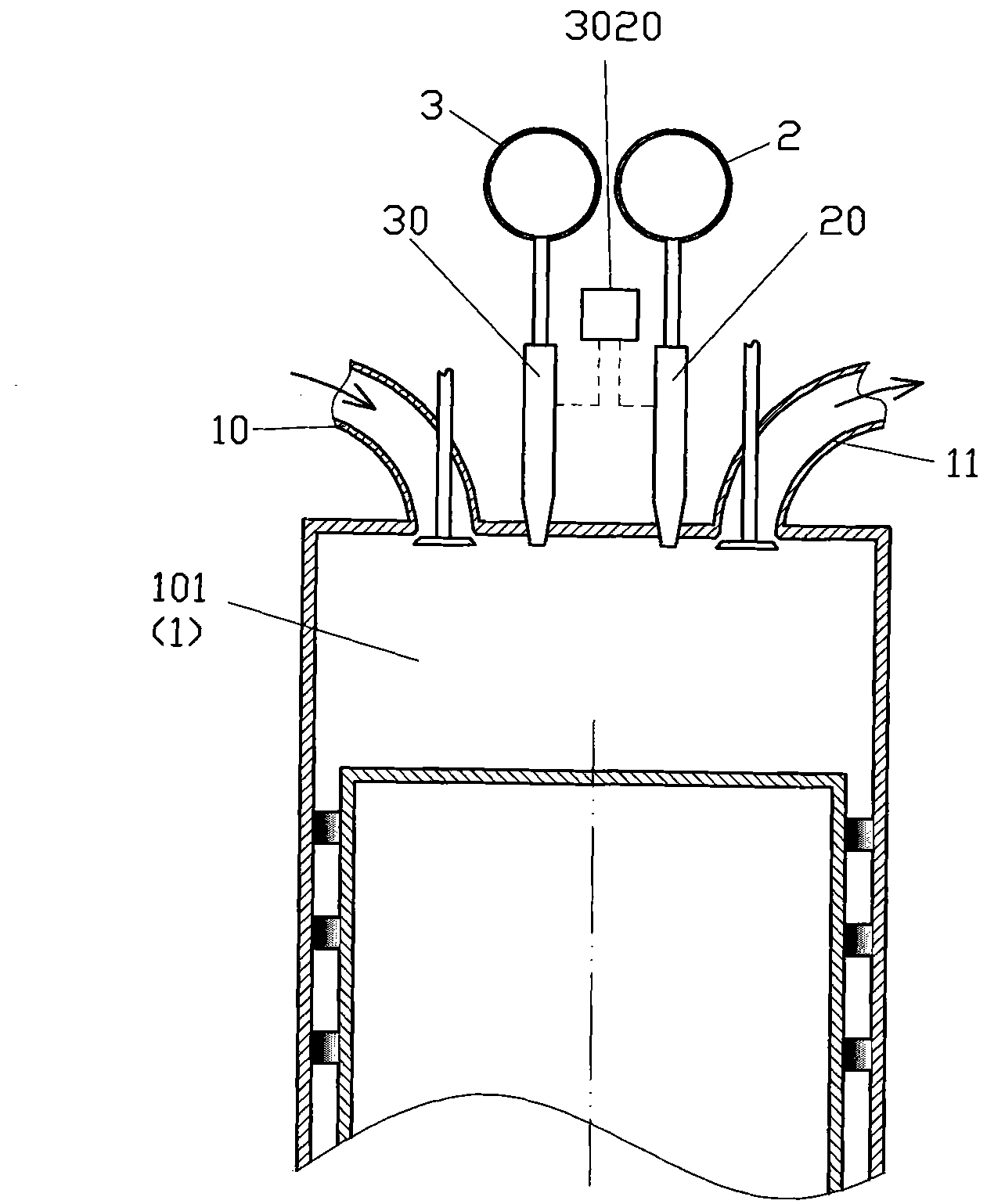

Embodiment 1

[0068] like figure 1 The shown small temperature rise and low entropy mixed combustion engine includes a combustion chamber 1, an expander source 2 and a fuel source 3, and the combustion chamber 1 is set as a piston engine combustion chamber 101 or as a turbine combustion chamber 102, and the fuel The source 3 communicates with the combustion chamber 1 through the fuel introduction control mechanism 30, the expansion agent source 2 communicates with the combustion chamber 1 through the expansion agent introduction control mechanism 20, and the fuel introduction control mechanism 30 and the expansion agent introduction The control mechanism 20 is controlled by the combustion control device 3020 to realize that more than 5% of the heat generated by the combustion of the fuel entering the combustion chamber 1 in the fuel source 3 has been introduced into the combustion chamber 1 in the combustion chamber 1 The expansion agent in the expansion agent source 2 absorbs; in the stru...

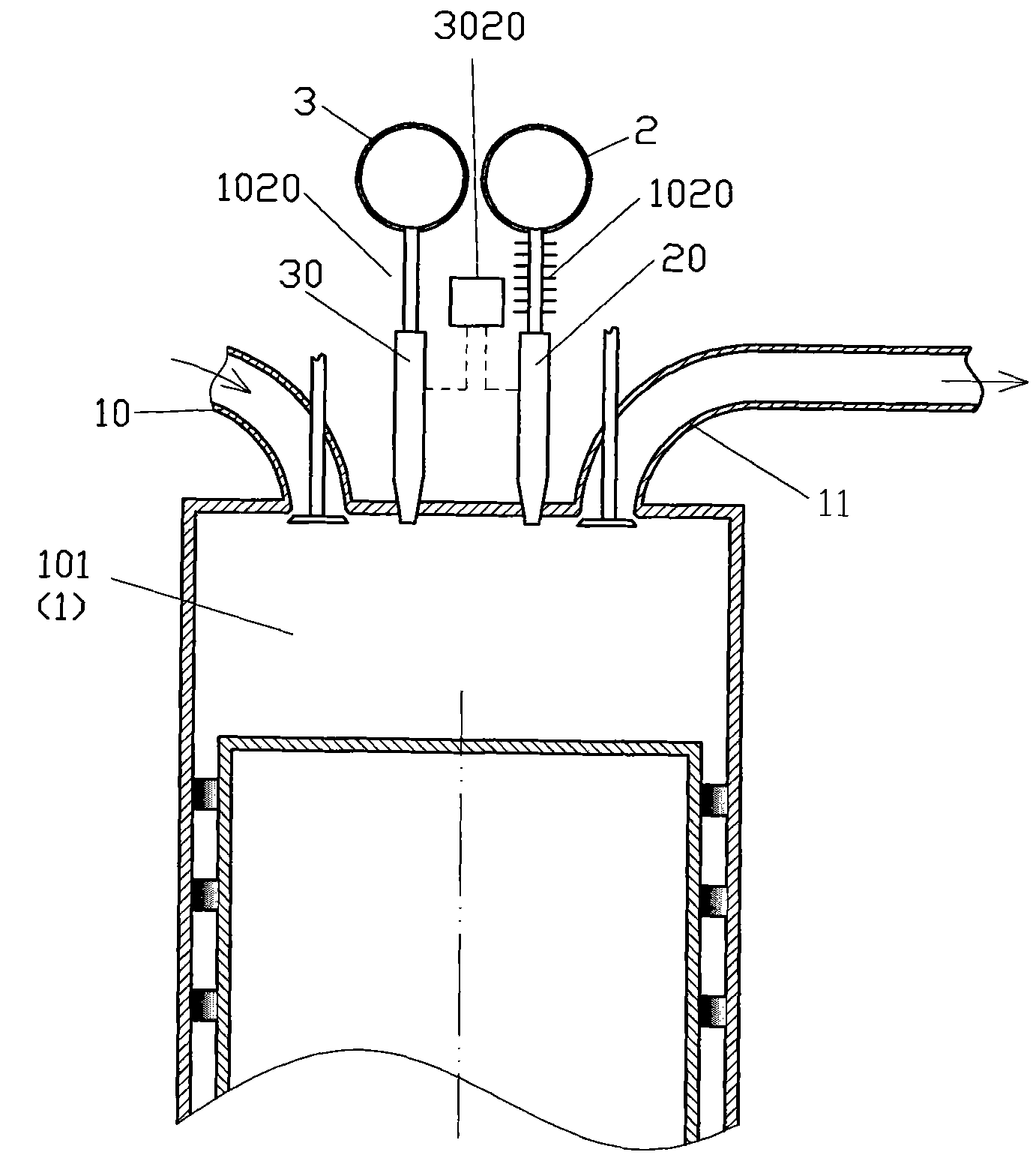

Embodiment 2

[0074] like figure 2 The difference between the small temperature-rise and low-entropy co-combustion engine shown in Embodiment 1 is that an expander heat absorbing heat exchanger 1020 is set between the combustion chamber 1 and the expander source 2 to make the expander The expansion agent in the agent source 2 absorbs heat in the expansion agent heat absorption heat exchanger 1020, and the combustion chamber 1 is set as an adiabatic combustion chamber.

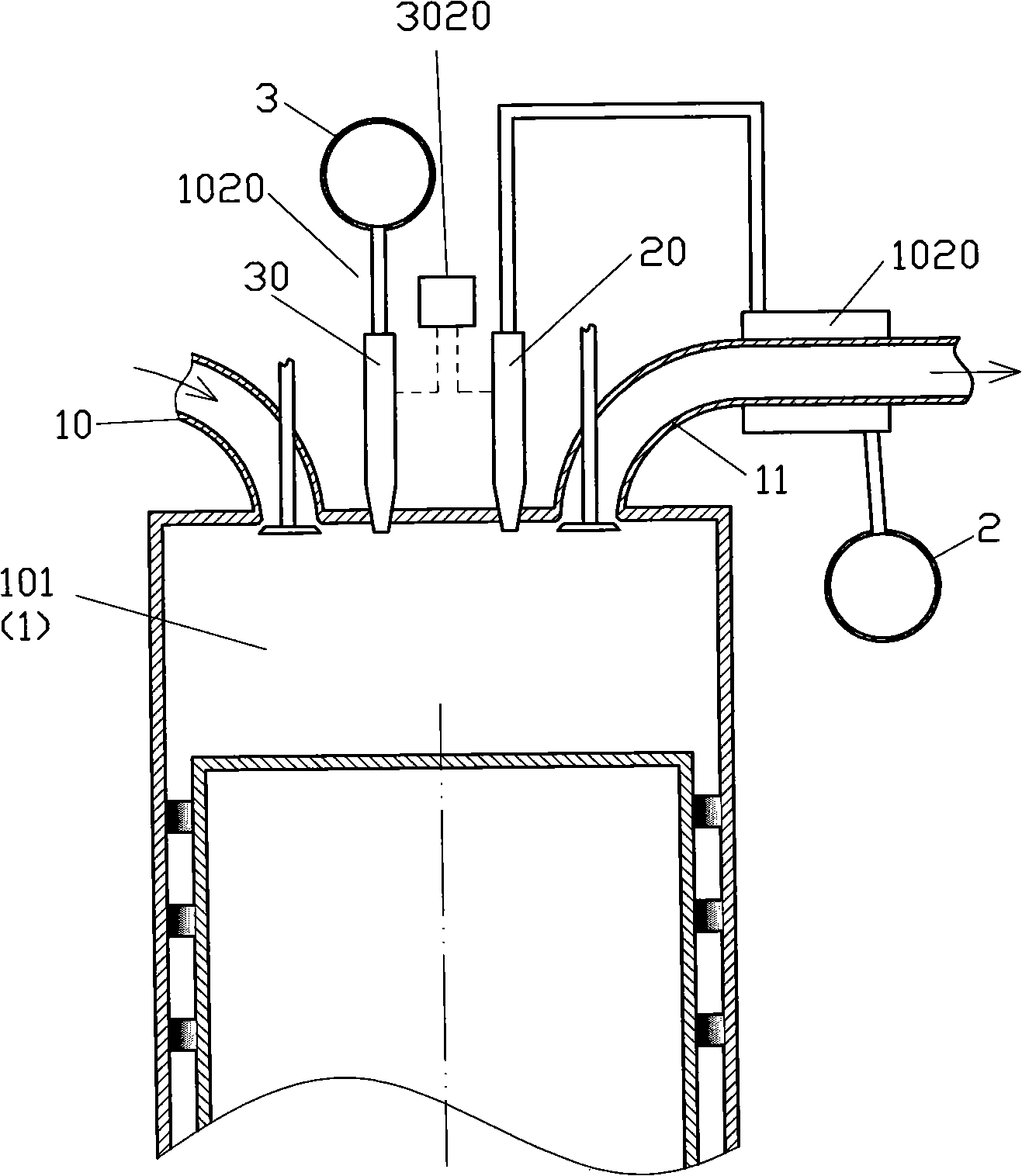

Embodiment 3

[0076] like image 3 The difference between the low-temperature-rise low-entropy co-combustion engine shown and Embodiment 1 is that the heat source of the expander heat absorption heat exchanger 1020 is set as the waste heat of the low-temperature-rise low-entropy co-combustion engine. The expansion agent in the expansion agent source 2 enters the combustion chamber 1 after absorbing heat in the expansion agent heat absorption heat exchanger 1020 to reach a critical state, a supercritical state or an ultra-supercritical state. The fuel in the fuel source 3 is set as ethanol, the expander in the expander source 2 is set as water, and the fuel source 3 and the expander source 2 are set as the same aqueous ethanol storage tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com