Electromechanical compound transmission device of tracked vehicle

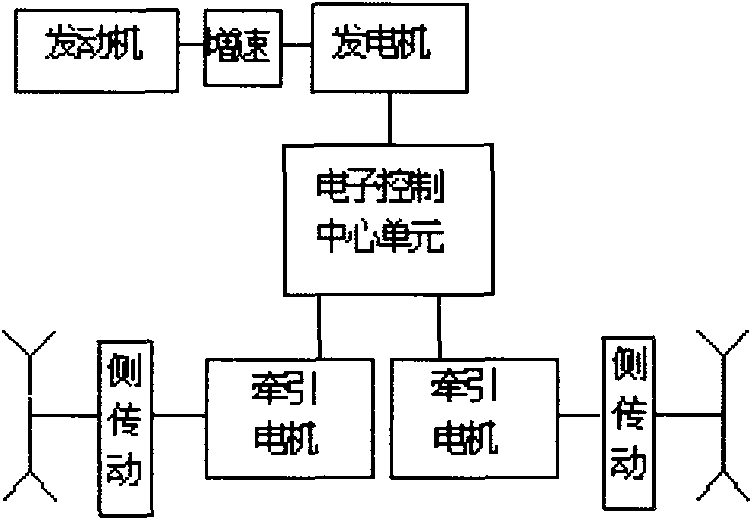

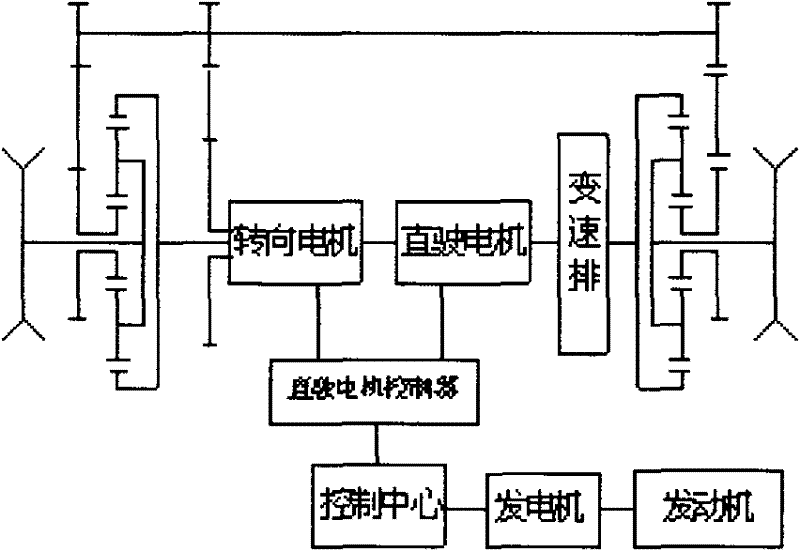

A technology of electromechanical composite transmission and transmission device, which is applied in the direction of power device, pneumatic power device, vehicle components, etc., can solve the problems of reducing the overall size of the transmission device and high requirements for traction motors, so as to achieve full utilization of system power and reduce research and development. Difficulty, small overall size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

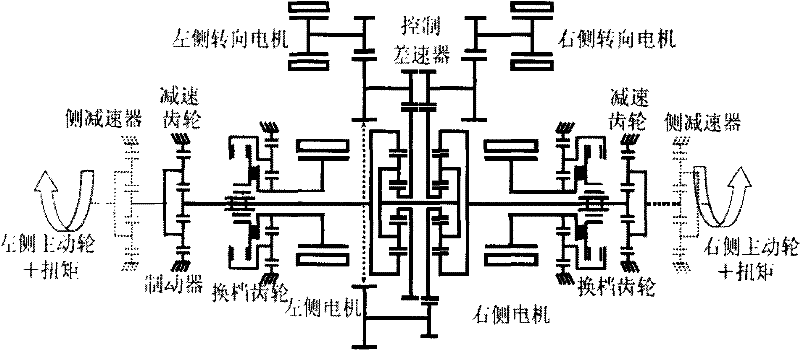

[0041] Example 1: climbing

[0042] The brakes 10 and 18 are closed, the clutches 3 and 7 are disconnected, and the transmission mechanisms on the left and right sides are in the first gear state; the power is converted into electric energy by the engine 13 through the generator 15 and then transmitted to the power control unit 16, through the frequency conversion controller 11 on the left Control the left side motor 6 and the right side motor 4 frequency conversion controllers (11,17) with the right frequency conversion controller 17 and control the left and right side motors (4,6) to rotate at the same speed in the same direction, driving the vehicle to climb a slope.

Embodiment 2

[0043] Example 2: Normal driving

[0044] The brakes 10 and 18 are disconnected, the clutches 3 and 7 are closed, and the speed change mechanism on the left and right sides is in the second gear state; the power is converted into electric energy by the engine 13 through the generator 15 and then transmitted to the power control unit 16, through the left and right frequency conversion controllers ( 11,17) control the left and right side motors (4,6) to rotate in the same direction and at the same speed to drive the vehicle to run normally.

Embodiment 3

[0045] Example 3: Center Steering

[0046] The brakes 10 and 18 are closed, the clutches 3 and 7 are disconnected, and the transmission mechanisms on the left and right sides are in the first gear state; the power is converted into electric energy by the engine 13 through the generator 15 and then transmitted to the power control unit 16, through the frequency conversion controller 11 on the left And the right frequency conversion controller 17 controls the left motor 6 and the right motor 4 to rotate at the same speed in the opposite direction, so as to realize the center steering of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com