Preparation process of selective reduction catalyst for lean-burn gasoline motor car exhausted gas nitrogen oxide

A technology for tail gas emission and nitrogen oxides, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problem of not many research reports and achieve high catalytic performance. Conversion efficiency, control of lean-burn vehicle exhaust emissions, and the effect of good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

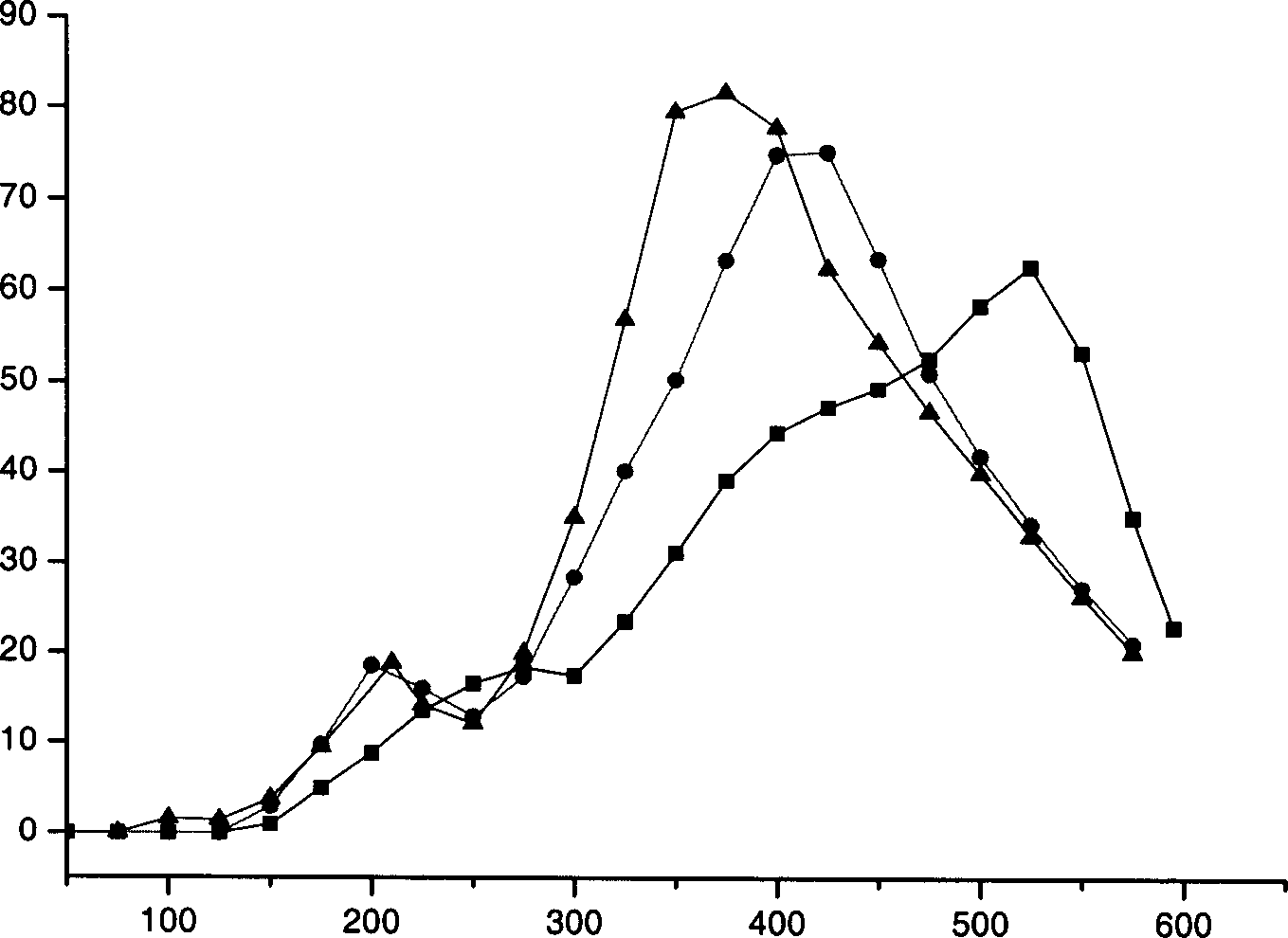

Image

Examples

Embodiment 1

[0022] Add dilute HNO to pseudoboehmite dry rubber powder 3and urea, and after stirring at high speed for 5 hours, an alumina sol with a solid content of 21 wt % was obtained. Immerse the 400-hole cordierite honeycomb ceramic monolith sample in the above sol for 1 minute, blow off the excess sol in the carrier channel with compressed air after taking it out, then place the carrier sample at room temperature to dry in the shade (32°C) for 6 hours, and put it in an oven at 110°C. °C for 6 hours, and finally baked in a muffle furnace at 600 °C for 2 hours to prepare a ceramic carrier with activated alumina coating.

[0023] The above-mentioned ceramic carrier with alumina coating is impregnated with a certain concentration of silver nitrate aqueous solution in an equal volume, then dried in an oven at 110 ° C, and finally roasted in a muffle furnace at 600 ° C for 3 hours to obtain Ag / Al 2 o 3 Monolithic catalyst with 2 wt% Ag loading.

Embodiment 2

[0025] A certain concentration of silver nitrate aqueous solution is impregnated with the ceramic support with alumina coating prepared in Example 1 in the following excessive impregnation mode: according to the saturated water absorption of the alumina coating on the honeycomb ceramic support and Loading capacity, calculate the concentration of silver nitrate solution, prepare the corresponding silver nitrate solution, the coated Al 2 o 3 The coated carrier is immersed in the silver nitrate solution prepared above for 30-120 minutes, and then the carrier is taken out, and the excess silver nitrate solution remaining in the pores of the catalyst carrier is blown out with compressed air. Then the catalyst was heated and dried in an oven at 110°C, and finally calcined in a muffle furnace at 600°C for 3 hours to obtain Ag / Al 2 o 3 Monolithic catalyst with 2 wt% Ag loading.

Embodiment 3

[0027] The ceramic carrier with alumina coating prepared in Example 1 was impregnated with a silver nitrate aqueous solution of a certain concentration in the excessive impregnation method described in Example 2, then dried by microwave for 10 minutes, and finally calcined in a muffle furnace at 600 ° C for 3 hours to obtain Ag / Al 2 o 3 Monolithic catalyst with 2 wt% Ag loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com