Composite loading nano-titania carrier and its prepn

A nano-titanium dioxide, composite carrier technology, applied in titanium dioxide, catalyst carrier, chemical instruments and methods, etc., can solve the problems of high impurity content and affecting catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 (γ-Al 2 o 2 Load 5 ~ 10nm (1nm = 10 -9 m) TiO with a content of 10 wt% 2 )

[0015] Preparation:

[0016] Beat the pseudo-boehmite in an appropriate amount of water for 2 hours (the amount of water: (water absorption of pseudo-boehmite (ml / g)+0.5) * The amount of pseudo-boehmite (g)).

[0017] Titanium colloid was prepared according to butyl titanate: absolute ethanol: water: nitric acid (molar ratio) of 1:9:3:0.3.

[0018] Under vigorous stirring, press the loaded TiO 2 10wt% ratio, drop an appropriate amount of titanium glue into the slurry of pseudo-boehmite and water, and then place it in the air to dry naturally for 24 hours, dry at 60°C for 12 hours, and dry at 120°C for 4 hours, then dry at 200, 300 , 400, and 550°C for 2 hours in sequence.

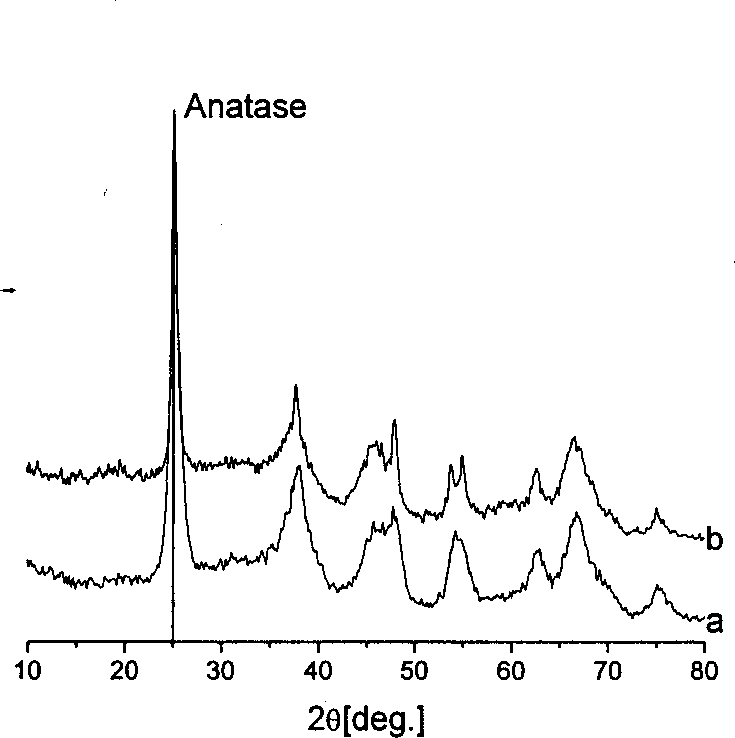

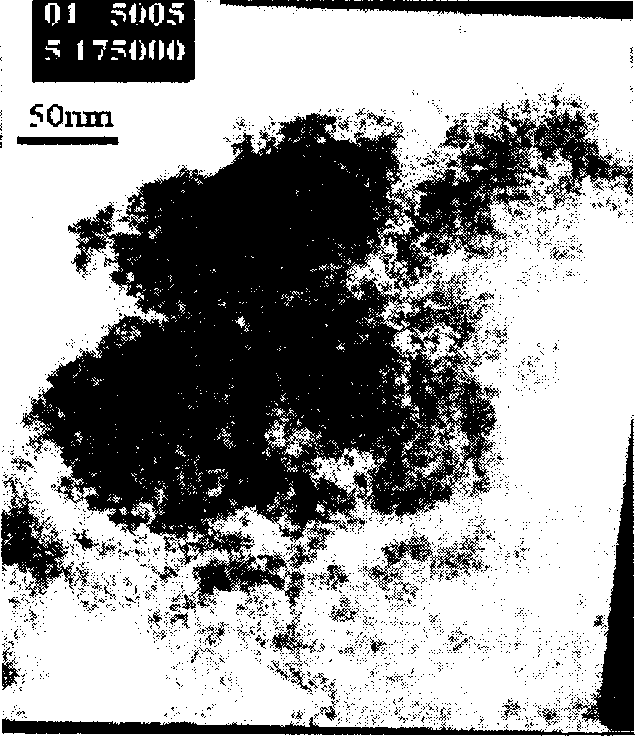

[0019] Supported TiO can be found by XRD spectrum 2 For the anatase type. Calculation of TiO by XRD diffraction broadening method 2 The average particle size is 9nm. Observed by TEM, TiO 2 The particl...

Embodiment 2

[0020] Example 2 (γ-Al 2 o 3 Loading 5~10nm content is 20wt% TiO 2 )

[0021] Preparation method is the same as embodiment 1, by TiO 2 Titanium gel was prepared with a loading of 20wt% and dropped into the slurry of pseudo-boehmite and water, and then placed in the air to dry naturally for 24 hours, at 60°C for 12 hours, at 120°C for 4 hours, and then at 200°C , 300, 400, and 550°C for 2 hours in sequence.

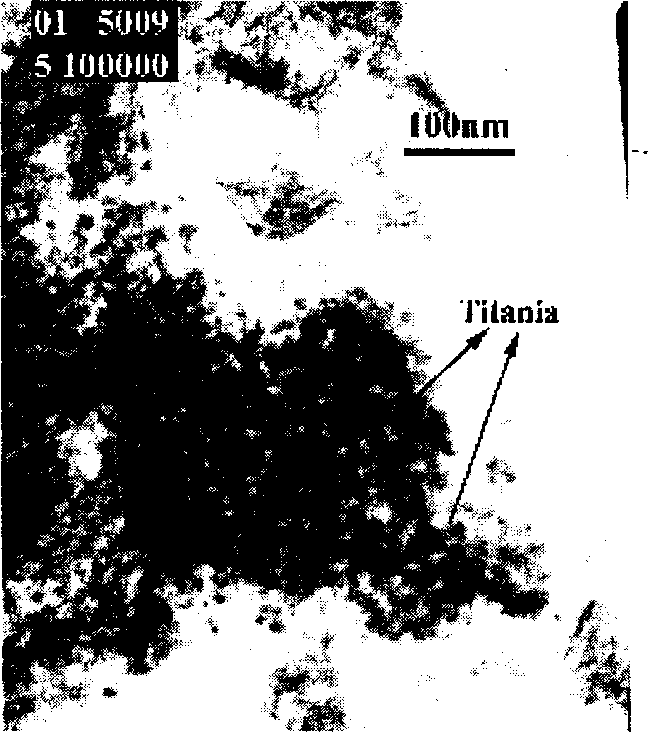

[0022] Through XRD experiments (results shown in Figure 1a), supported TiO 2 It is anatase type with an average particle size of 7.9nm. Observed by TEM (results shown in Figure 2), TiO 2 The particle size is between 5 and 10nm.

Embodiment 3

[0023] Example 3 (γ-Al 2 o 3 Loading 15~20nm content is 10wt% TiO 2 )

[0024] Preparation:

[0025] Immerse pseudo-boehmite in an appropriate amount of absolute ethanol for 2 hours (the amount of absolute ethanol: (pseudo-boehmite ethanol absorption rate (ml / g)+0.5) * Amount of pseudo-boehmite (g)).

[0026] Titanium colloid was prepared according to butyl titanate: absolute ethanol: water: nitric acid (molar ratio) of 1:9:3:0.3.

[0027] Under vigorous stirring, press the loaded TiO 2 The proportion of 10wt%, drop an appropriate amount of titanium glue into the slurry made of pseudo-boehmite and absolute ethanol. Then place it in the air to dry naturally for 24 hours, at 60°C for 12 hours, and at 120°C for 4 hours. Then calcined at 200, 300, 400, 550° C. for 2 hours.

[0028] Supported TiO can be found by XRD spectrum 2 For the anatase type. Calculation of TiO by XRD diffraction broadening method 2 The average particle size is 18.8nm. Observed by TEM, TiO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com