Lightweight iolite-mullite composite ceramic material and preparation method thereof

A technology of composite ceramics and composite materials, which is applied in the field of lightweight cordierite-mullite composite ceramic materials and its preparation, can solve the problems of uneven distribution of phase composition, low thermal shock resistance, and high impurity content, and achieve Uniform distribution, low price, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

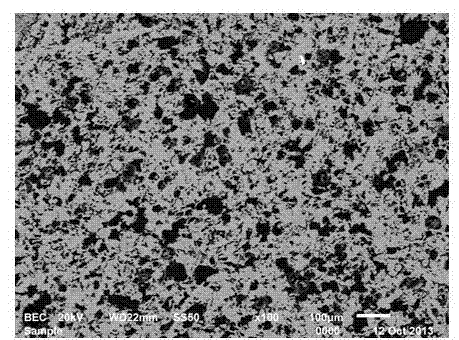

Image

Examples

Embodiment 1

[0023] A light cordierite-mullite composite ceramic material and a preparation method thereof. The concrete steps of this method are:

[0024] Step 1, using 20-40wt% diaspore, 10-18wt% amorphous silica, 20-30wt% talcum powder and 30-40wt% clay as raw materials, plus 7-10wt% of the raw materials Water, stir evenly, machine press molding under the condition of 60~80MPa, dry the molded green body at 100~150℃ for 12~24 hours, raise the temperature to 1250~1280℃, keep it warm for 2~4 hours, and make porous viola Bluestone-mullite composite.

[0025] Step 2, breaking the obtained porous cordierite-mullite composite material into porous cordierite-mullite composite material particles with a particle size of 2-1 mm, and porous cordierite-mullite composite material with a particle size of 1-0.088 mm Material particles and porous cordierite-mullite composite material powder with particle size less than 0.088mm.

[0026] Step 3, with 20~40wt% of porous cordierite-mullite composite mat...

Embodiment 2

[0030] A light cordierite-mullite composite ceramic material and a preparation method thereof. The concrete steps of this method are:

[0031] Step 1, using 30~50wt% diaspore, 15~20wt% amorphous silica, 15~20wt% talcum powder and 20~30wt% clay as raw materials, plus 5~7wt% of the raw materials Water, stir evenly, machine press molding under the condition of 60~80MPa, dry the molded green body at 150~300℃ for 24~36 hours, raise the temperature to 1280~1320℃, keep it warm for 4~6 hours, and make porous viola Bluestone-mullite composite.

[0032]Step 2, breaking the obtained porous cordierite-mullite composite material into porous cordierite-mullite composite material particles with a particle size of 2-1 mm, and porous cordierite-mullite composite material with a particle size of 1-0.088 mm Material particles and porous cordierite-mullite composite material powder with particle size less than 0.088mm.

[0033] Step 3, with 30~50wt% of porous cordierite-mullite composite mater...

Embodiment 3

[0037] A light cordierite-mullite composite ceramic material and a preparation method thereof. The concrete steps of this method are:

[0038] Step 1, using 50-70wt% diaspore, 15-25wt% amorphous silica, 5-15wt% talcum powder and 10-20wt% clay as raw materials, plus 3-5wt% of the raw materials Water, stir evenly, machine press molding under the condition of 80~100MPa, dry the molded green body at 150~300℃ for 12~24 hours, raise the temperature to 1300~1350℃, keep it warm for 2~4 hours, and make porous viola Bluestone-mullite composite.

[0039] Step 2, breaking the obtained porous cordierite-mullite composite material into porous cordierite-mullite composite material particles with a particle size of 2-1 mm, and porous cordierite-mullite composite material with a particle size of 1-0.088 mm Material particles and porous cordierite-mullite composite material powder with particle size less than 0.088mm.

[0040] Step 3, with 40~50wt% of porous cordierite-mullite composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com