A kind of preparation method of BSAS composite ceramic powder

A composite ceramic and powder technology, applied in coating, metal material coating process, melt spraying and other directions, to achieve the effect of easy to achieve batch preparation, reduce phase transition temperature, and promote nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

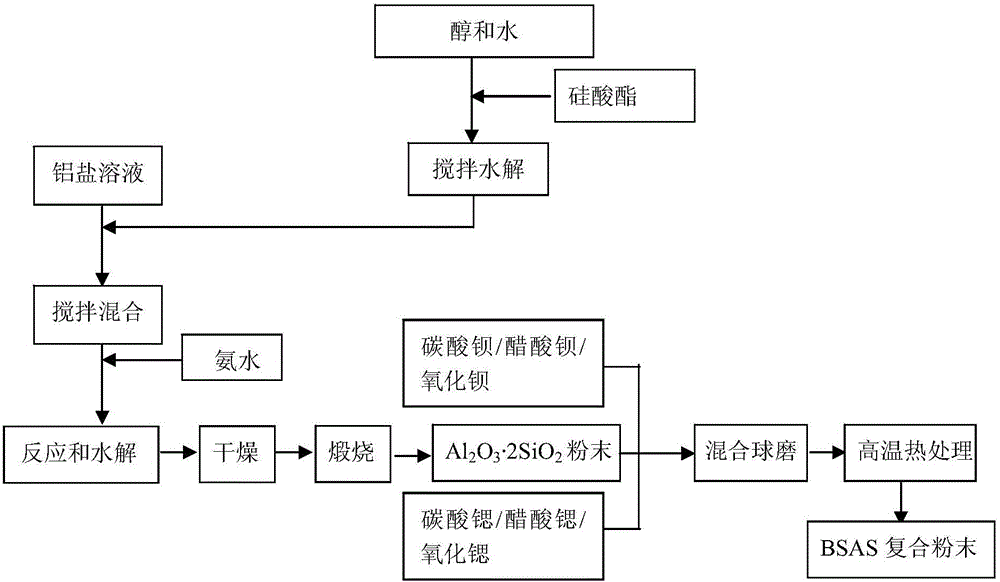

Method used

Image

Examples

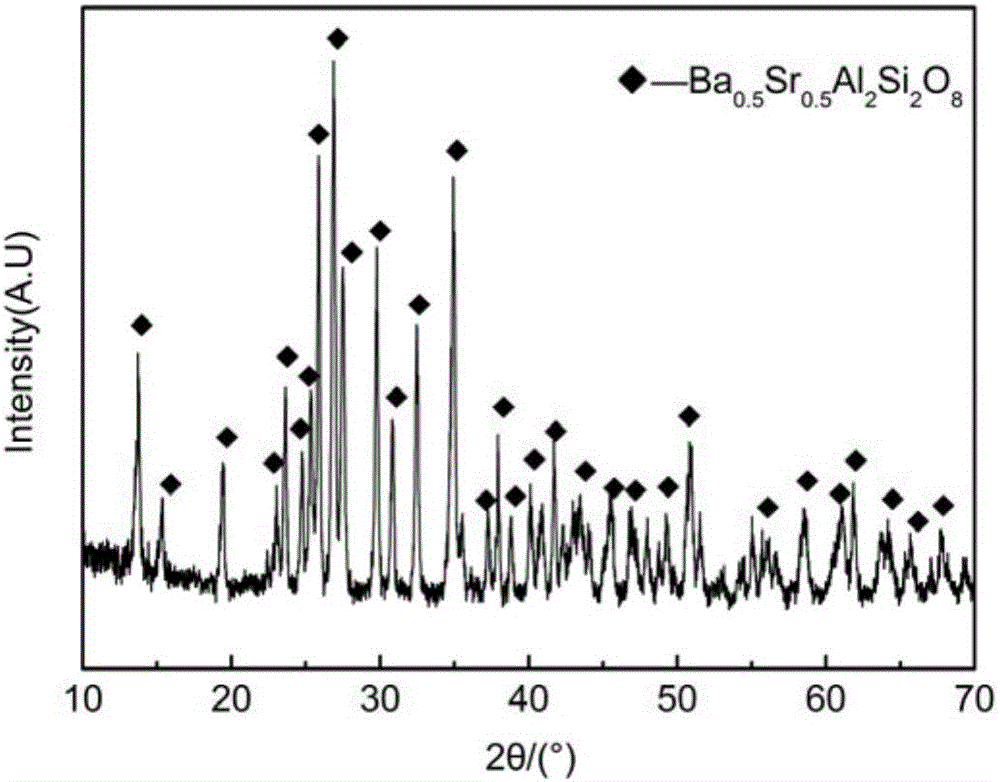

Embodiment 1

[0041] To prepare 0.5BaO-0.5SrO-Al 2 o 3 -2SiO2 2 (BSAS) 10 kg of composite ceramic powder is an example, the converted mole number is 28.52 mol, and Al in the composition 2 o 3 The number of moles is 28.52mol, then the raw material Al(NO 3 ) 3 9H 2 The number of moles of O is 57.04 mol, and the converted mass is 21.4 kg. Weigh 21.4 kg of solid aluminum nitrate and dissolve in deionized water to form a transparent aluminum nitrate solution. SiO in 10 kg BSAS powder 2 The number of moles is 57.04mol, and the converted quality is 3.43 kilograms, and the used tetraethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ) in SiO 2 The content is 28%, the density is 0.929g / cm 3 , then the mass of ethyl orthosilicate is 12.25 kg, and the volume of ethyl orthosilicate is 13.2L. Measure 13.2L of tetraethyl orthosilicate and 15.4 kg of ethanol, mix the measured tetraethyl orthosilicate and ethanol, add it to the aluminum nitrate solution, stir for 30 minutes to make it fully mixed, and t...

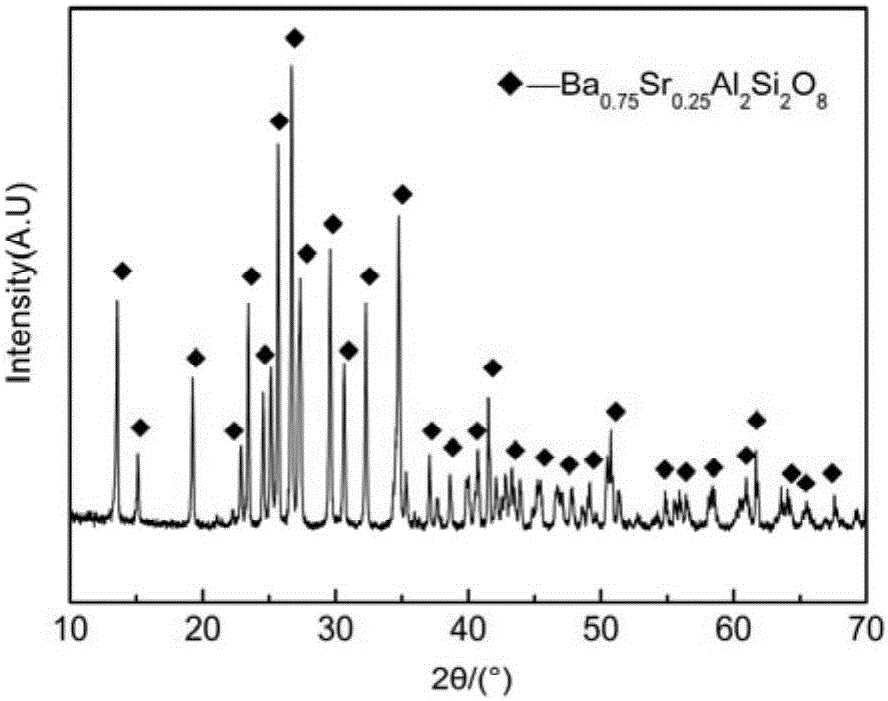

Embodiment 2

[0044] To prepare 0.75BaO-0.25SrO-Al 2 o 3 -2SiO2 2 (BSAS) 10 kg of composite ceramic powder is an example, the converted mole number is 27.55 mol, and Al in the composition 2 o 3 The number of moles is 27.55mol, then the raw material Al(NO 3 ) 3 9H 2 The number of moles of O is 55.1 mol, and the converted mass is 20.7 kg. Weigh 20.7 kg of solid aluminum nitrate and dissolve in deionized water to form a transparent aluminum nitrate solution. SiO in 10 kg BSA powder 2 The number of moles is 55.1mol, and the converted quality is 3.31 kilograms, and the used tetraethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ) in SiO 2 The content is 28%, the density is 0.929g / cm 3 , then the mass of ethyl orthosilicate is 11.82 kg, and the volume of ethyl orthosilicate is 12.7L. Measure 12.7L of tetraethyl orthosilicate and 14.8 kg of ethanol, mix the measured tetraethyl orthosilicate and ethanol, add it to the aluminum nitrate solution, stir for 30 minutes to make it fully mixed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com