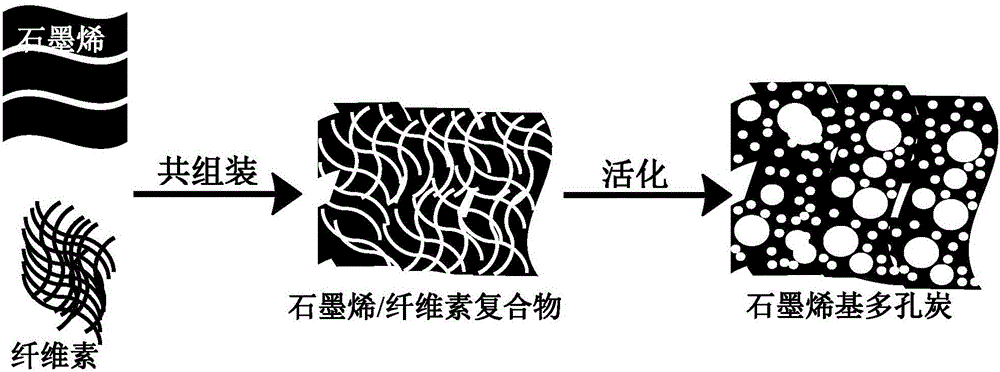

A kind of graphene-based hierarchical porous carbon material and its preparation method and application

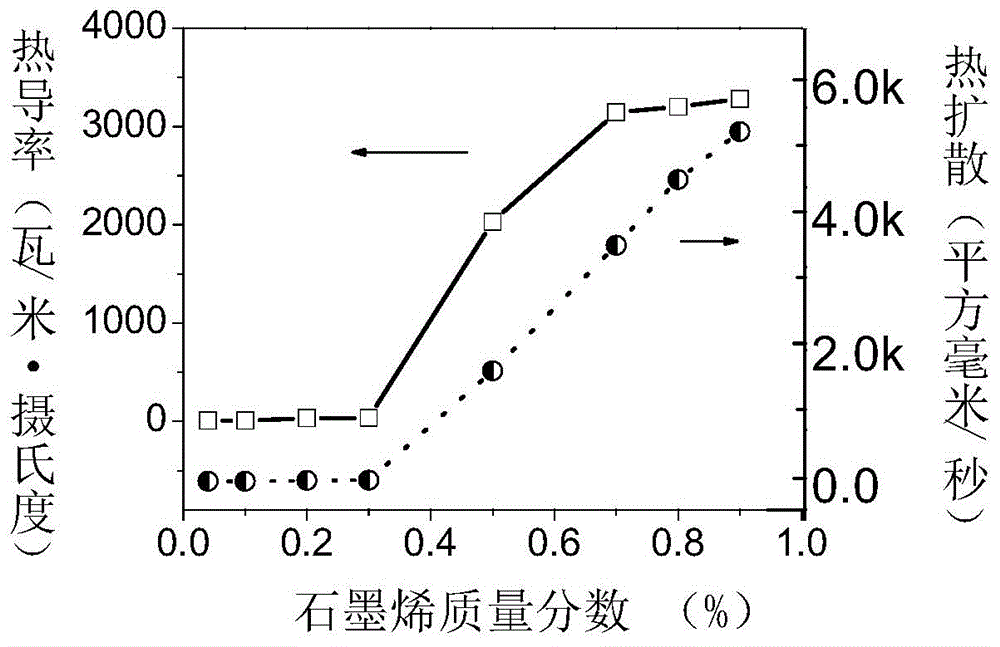

A graphene, graphene suspension technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of large specific surface area, high porosity, difficult to scale production, etc. The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

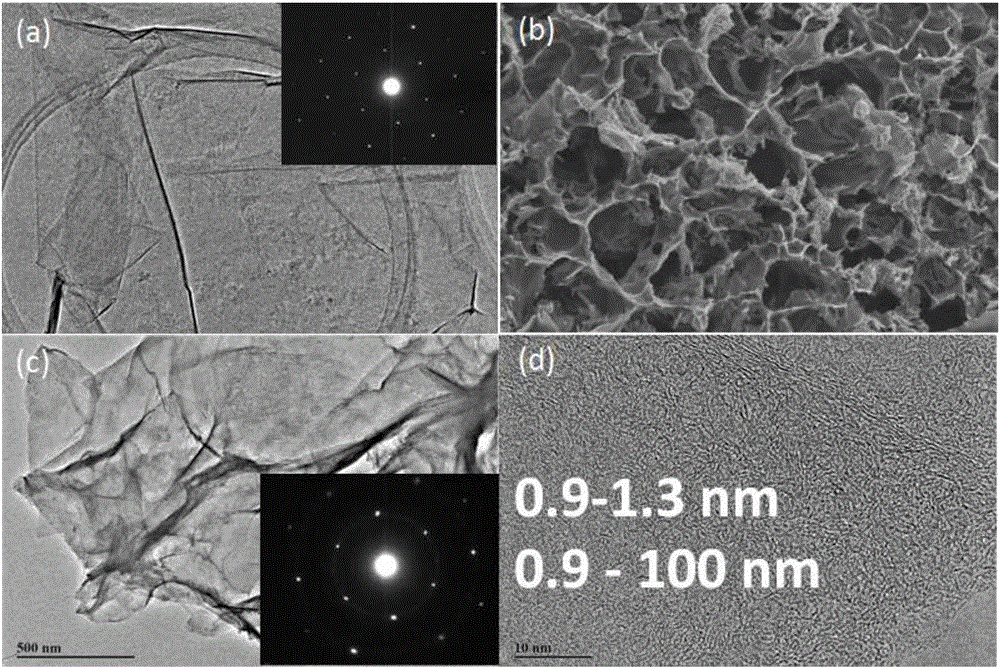

Embodiment 1

[0064] Application number 201310659172.5, named as a method for preparing graphene from electrochemically swollen graphite, has a carbon / oxygen atomic ratio of 71% in the graphene sample obtained in Example 2 of the patent, and the graphene unit reaches 200 microns × 200 microns, 70% of the sample The number of graphene layers is 2-3 atomic layers. Commercial microcrystalline cellulose (particle size 10 μm) was used as raw material. Disperse the graphene powder in the water solvent, under ultrasonic conditions: power 60 watts (60 W), time 5 minutes (5 min), temperature maintained at 25 degrees Celsius (25 degrees Celsius), to prepare a uniformly dispersed graphene suspension, Its concentration is 0.3 mg / mL. Disperse the microcrystalline cellulose powder in the water solvent, under ultrasonic conditions: power 50 watts (50 W), time 5 minutes (5 min), temperature maintained at 25 degrees Celsius (25 degrees Celsius), to prepare a uniformly dispersed cellulose suspension soluti...

Embodiment 2

[0067] Adopt application number 201310659172.5, named as a method for preparing graphene by electrochemically swelling graphite. The carbon / oxygen atomic ratio of the graphene sample obtained in Example 3 in the patent is 70%, and the graphene unit reaches 200 microns × 200 microns, 67% in the sample. The number of graphene layers is 2-3 atomic layers. Commercial cellulose fibers (particle size 60 microns) were used as raw materials. Disperse graphene powder in ethanol solvent, under ultrasonic conditions: power 80 watts (80 W), time 10 minutes (10 min), temperature maintained at 30 degrees Celsius (30 degrees Celsius), to prepare a uniformly dispersed graphene suspension, Its concentration is 1.0 mg / mL. Disperse the cellulose powder in ethanol solvent, under ultrasonic conditions: power 80 watts (80 W), time 10 minutes (10 min), temperature maintained at 30 degrees Celsius (30 degrees Celsius), to prepare a uniformly dispersed cellulose suspension, Its concentration is 100 ...

Embodiment 3

[0070] Adopt application number 201310659172.5, named as a method for preparing graphene by electrochemically swelling graphite. The carbon / oxygen atomic ratio of the graphene sample obtained in Example 4 in the patent is 70% (XPS detection), and the graphene unit reaches 200 microns × 200 microns. 80% of the graphene layers in the sample are 2-3 atomic layers. Commercial natural cellulose (particle size 100 microns) was used as raw material. Disperse graphene powder in N,N-dimethylformamide (DMF) solvent, under ultrasonic conditions: power 100 watts (100 W), time 30 minutes (30 min), temperature maintained at 40 degrees Celsius (40°C) , prepared into a uniformly dispersed graphene suspension with a concentration of 7.5 mg / mL. Disperse cellulose (particle size: 100 µm) powder in propanol solvent, under ultrasonic conditions: power 100 watts (100 W), time 30 minutes (30 min), temperature maintained at 40 degrees Celsius (40°C), prepared into a uniform Dispersed cellulose susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com