A low-temperature synthesis method and application of silicon carbide-coated diamond composite powder

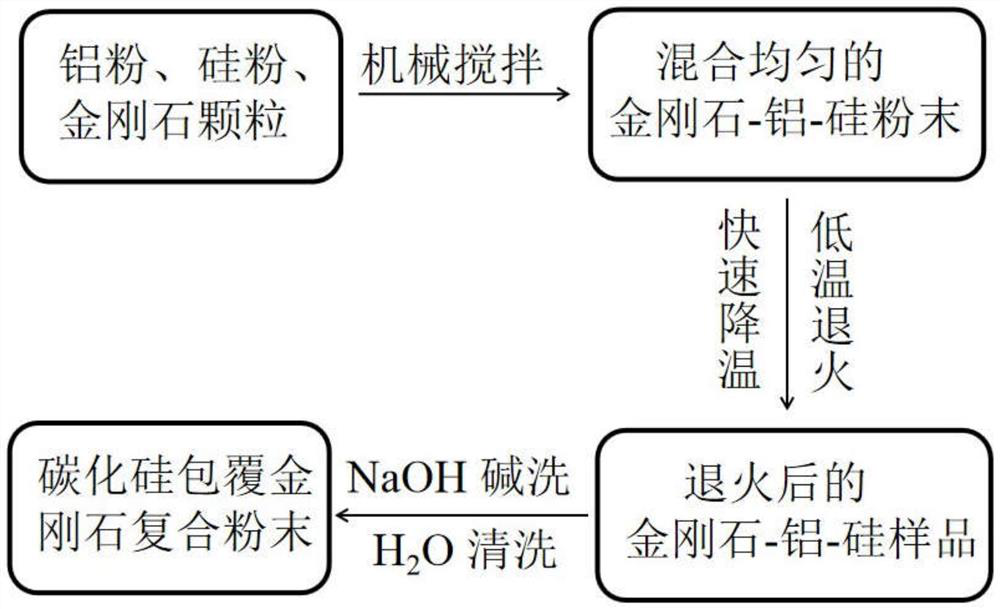

A synthesis method and technology of composite powder, which can be used in transportation and packaging, metal processing equipment, etc., can solve the problems of affecting thermal conductivity and not forming a continuous structure, and achieve the effect of improving thermal conductivity, simple method and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

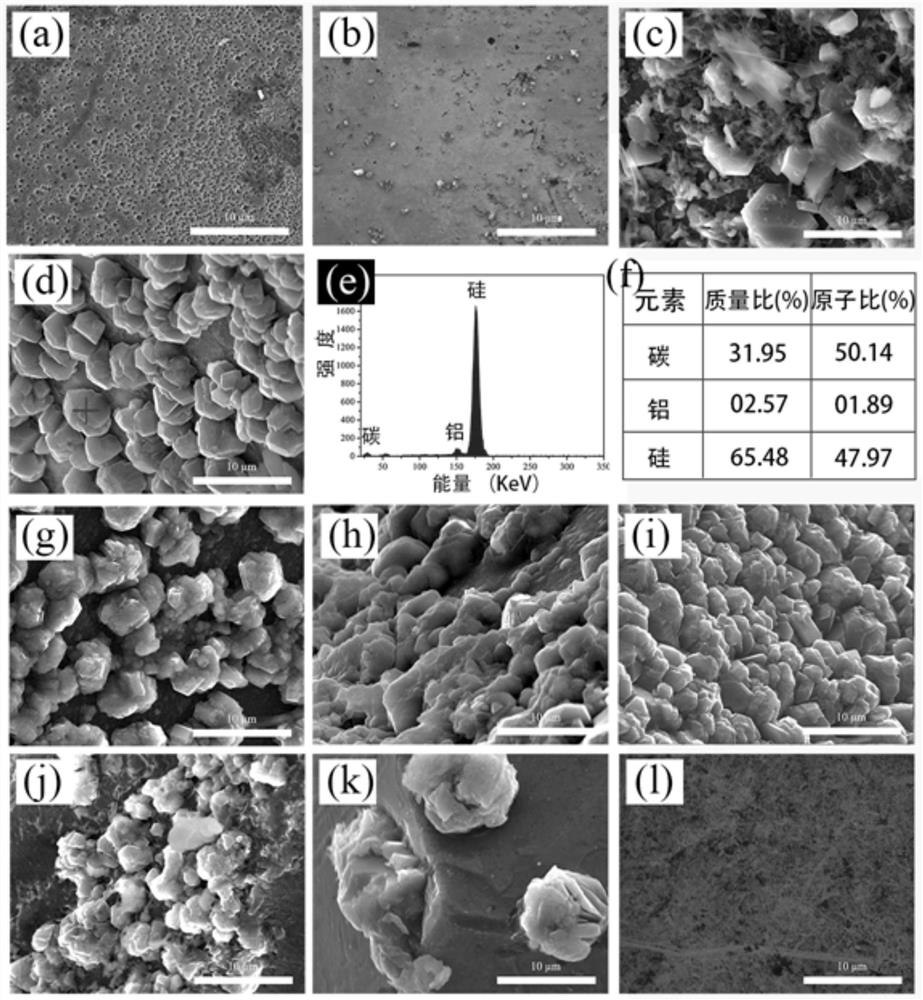

[0048] The silicon mass fraction is 7wt.%, 12.6wt.%, 20wt.%, 30wt.%, 40wt.%, 55wt.%, 70wt.%, 80wt.%, 90wt.%, 100wt.% aluminum silicon powder ( Composed of silicon powder with a particle size of 5-15 microns and aluminum powder with a particle size of 3-10 microns) are uniformly mixed with cleaned diamond particles (30-400 microns in particle size), wherein the aluminum-silicon mixed powder is mixed with The mass ratio of diamond particles is 1:1. Then put the evenly mixed diamond-aluminum-silicon powder into a vacuum tube annealing furnace, keep it warm at 800°C for 1 hour, cool it rapidly at a cooling rate of 40°C / min, and finally soak it in 5mol / L NaOH solution to The unreacted aluminum-silicon powder is removed, then washed with water and dried to obtain a silicon carbide-coated diamond composite powder. The morphology of silicon carbide prepared under different silicon mass fractions is as follows: figure 2 shown. SEM results show that when the mass fraction of silicon...

Embodiment 2

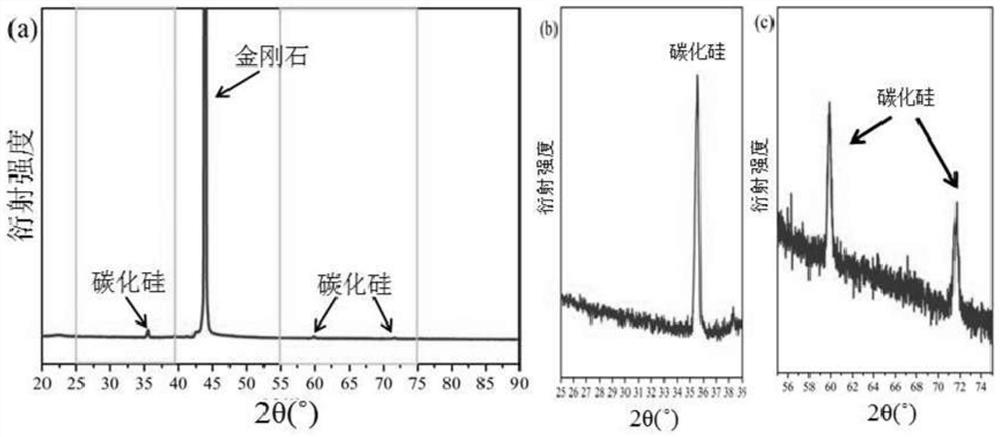

[0050] The SiC-coated diamond composite powder synthesized under the condition of 70wt.% silicon mass fraction in Example 1 was characterized by XRD. The test parameters: the scanning speed of the full spectrum (20°-90°) was 10° / min, and the narrow spectrum (25°-39°, 55°-75°) with a scanning speed of 1° / min, the results are as follows image 3 shown. Since the strong diamond peak masked the intensity of the SiC peak, only the diamond peak and the less obvious SiC peak were observed in the full spectrum. But in the two narrow caps, silicon carbide peaks can be clearly observed, which indicates that the particles observed in Example 1 are silicon carbide. From Example 1, it can be seen that under the annealing condition of 800°C for 1 hour, the mass fraction of silicon in the aluminum silicon powder has a significant impact on the distribution and morphology of the synthesized silicon carbide particles.

Embodiment 3

[0052] The silicon carbide coated diamond composite powder synthesized under the condition of silicon mass fraction of 70wt.% in Example 1 was characterized by Raman and XPS, and the corresponding results are as follows Figure 4 , Figure 5 shown. It is found from the figure that the series of results of Raman and XPS further confirmed that the particles on the surface of these composite powders are silicon carbide, which shows that this method can successfully synthesize silicon carbide on the surface of diamond at low temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com