Low density proppant

a proppant and low density technology, applied in the field of proppant, can solve the problems of increasing the wear of fluid carrying equipment, causing cracks or fractures, and increasing the densities of high-density proppants,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

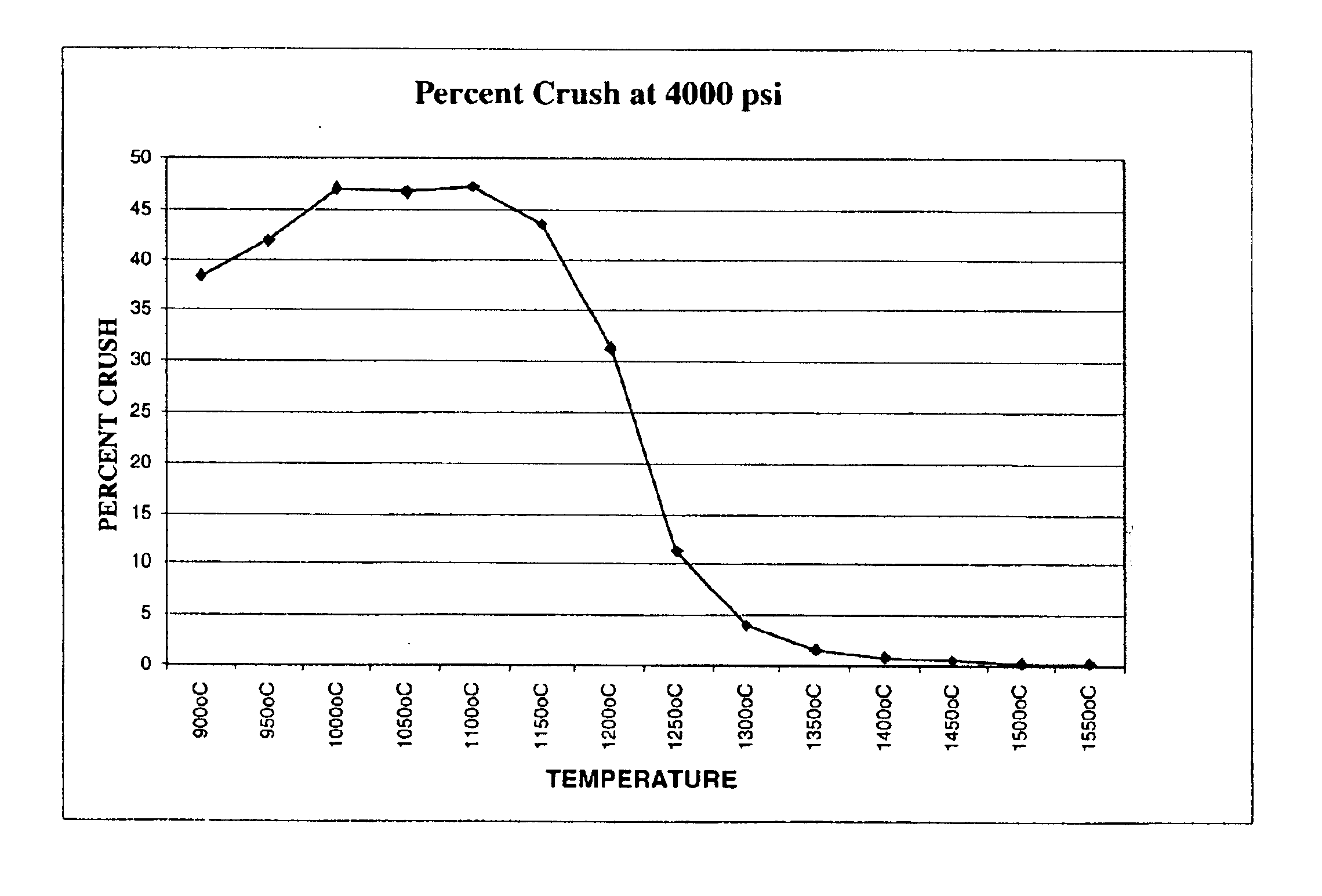

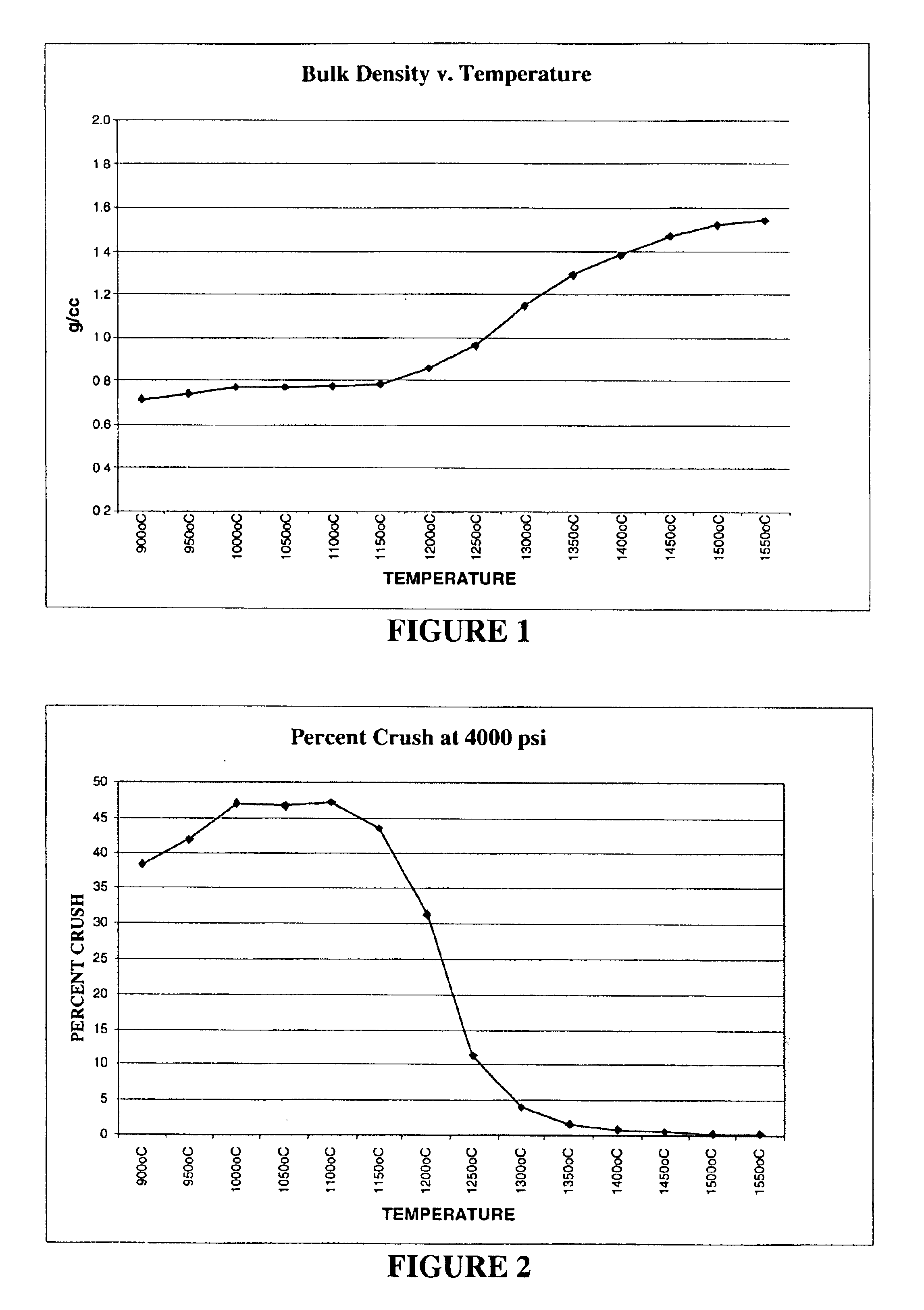

[0016]The proppant of the present invention is in the form of solid spherical pellets made from naturally occurring materials, such as kaolin clay. This invention is a proppant for use in shallow oil and gas wells which has an apparent specific gravity of from about 1.60 to about 2.10 g / cc and a bulk density of from about 0.95 to about 1.30 g / cc. Preferably, the alumina content is between about 40 and 60%. Most preferably, the proppant has an alumina content of about 50%.

[0017]One advantage of this lower density proppant is that fewer pounds of this proppant are required, as compared to higher density proppants, to fill a given void in the formation. Since proppants are generally sold by the pound, the user buys fewer pounds of proppant for a particular application. Another advantage of this low density proppant is the ability to use a lower viscosity fluid during pumping operations, resulting in more economical pumping at lower pumping rates than those required with the use of heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com