Method for making a chemical contrast pattern using block copolymers and sequential infiltration synthesis

a technology of chemical contrast and copolymer, which is applied in the field of block copolymer to make a chemical contrast pattern, can solve the problems of degrading the image quality of the original pattern, insufficient amount of inorganic material (alumina in the above example), and extremely low density of active sites where the ald precursor can bind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

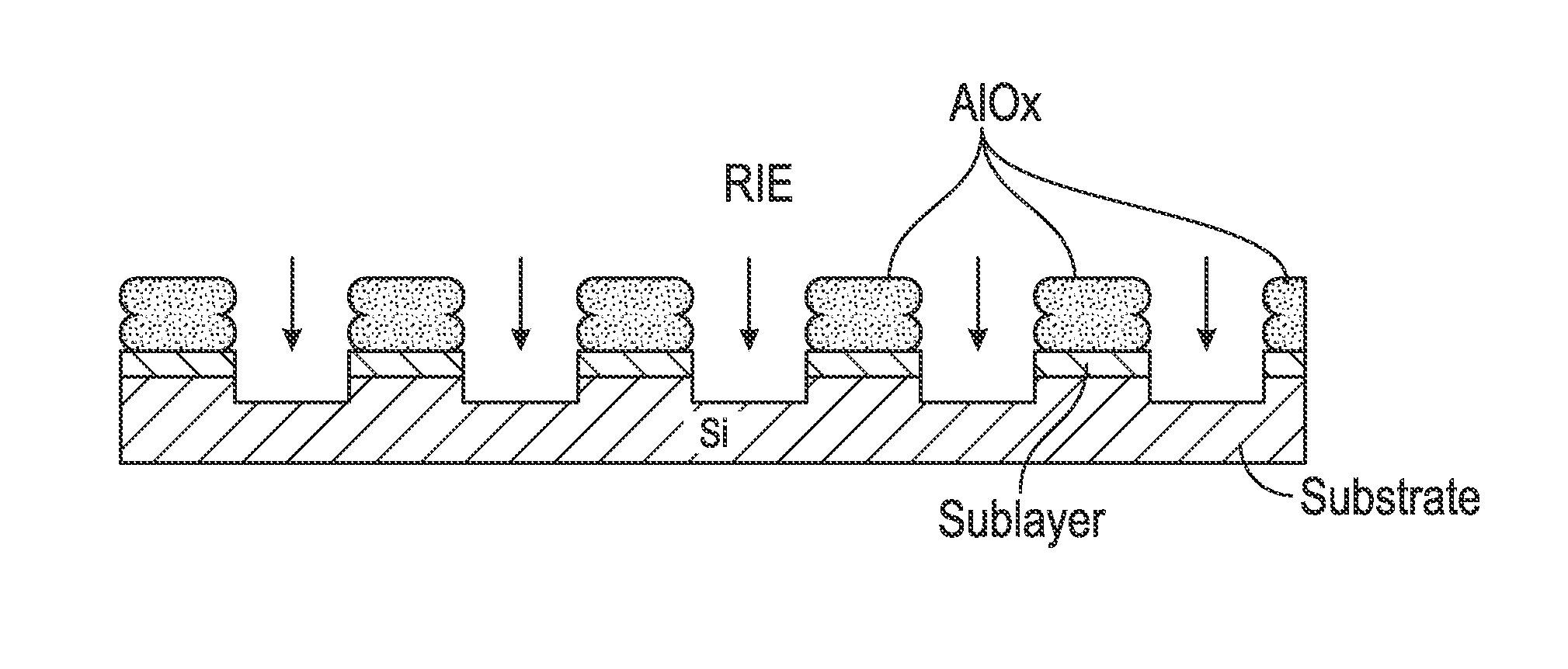

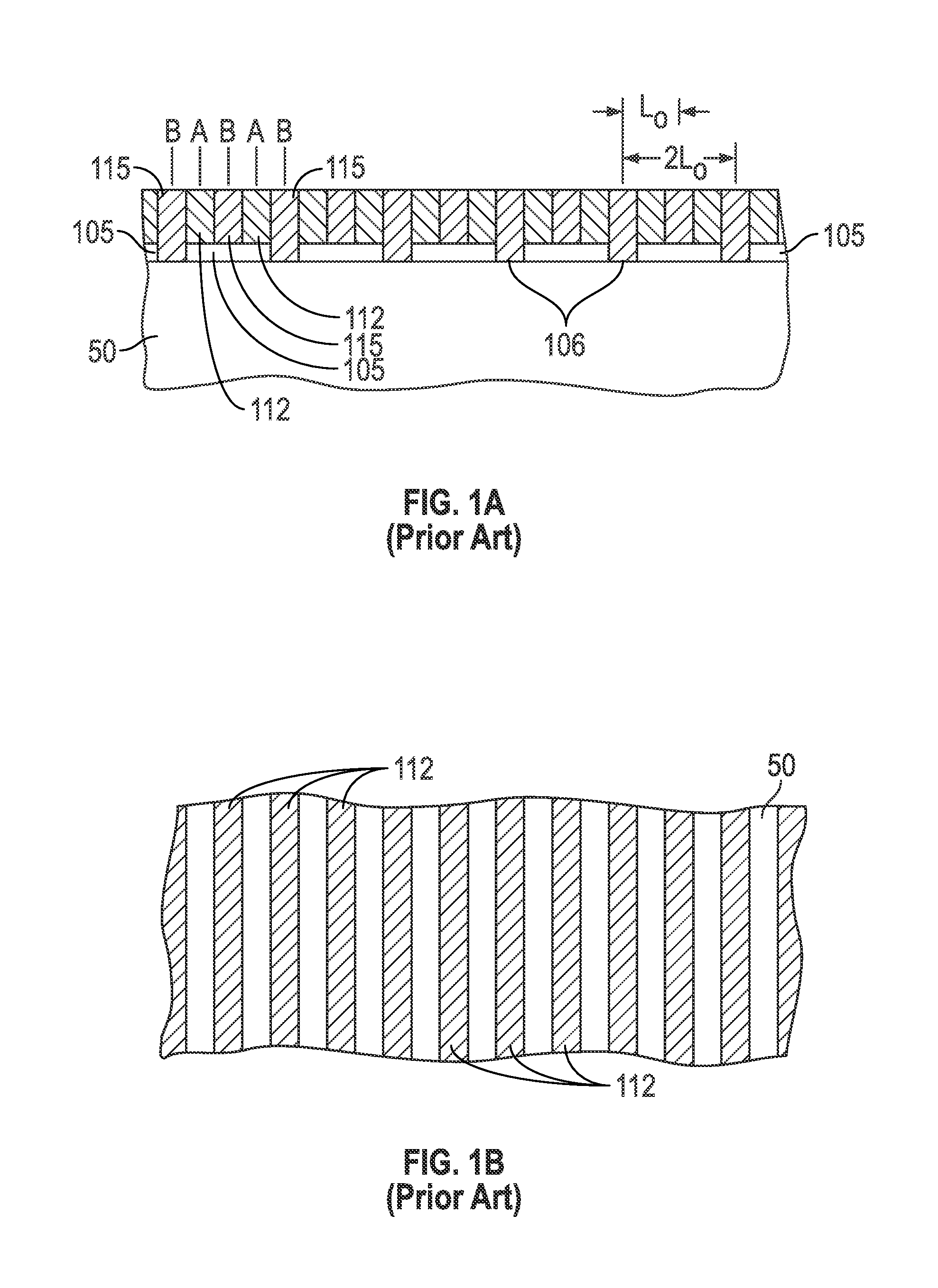

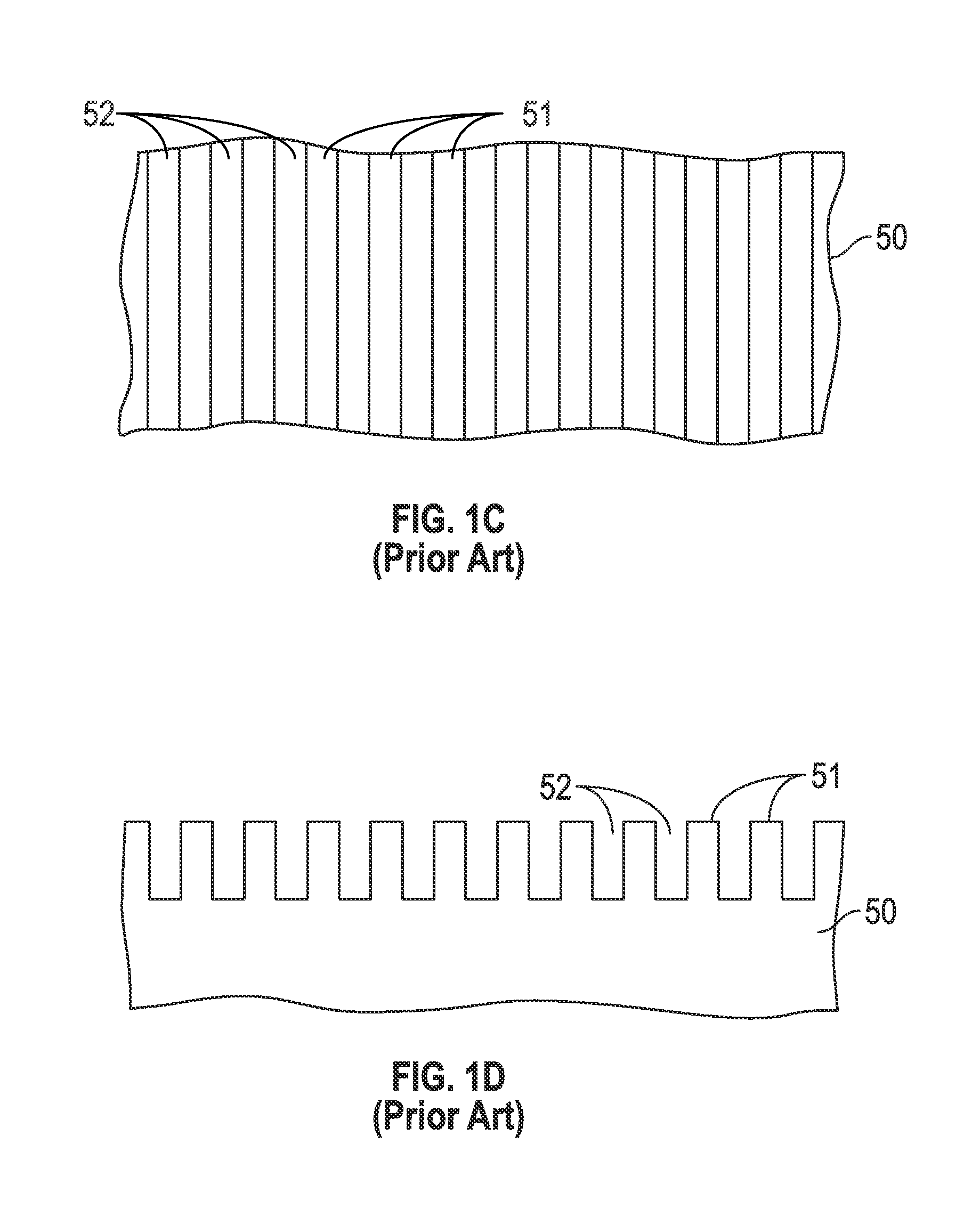

[0017]Self-assembling block copolymers (BCPs) have been proposed for creating periodic nanometer (nm) scale features. Self-assembling BCPs typically contain two or more different polymeric block components, for example components A and B, that are immiscible with one another. Under suitable conditions, the two or more immiscible polymeric block components separate into two or more different phases or microdomains on a nanometer scale and thereby form ordered patterns of isolated nano-sized structural units. There are many types of BCPs that can be used for forming the self-assembled periodic patterns. If one of the components A or B is selectively removable without having to remove the other, then an orderly arranged structural units of the un-removed component can be formed.

[0018]Specific examples of suitable BCPs that can be used for forming the self-assembled periodic patterns include, but are not limited to: poly(styrene-block-methyl methacrylate) (PS-b-PMMA), poly(ethylene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| center-to-center distance | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com