anti-scaling equipment

A kind of equipment and anti-scaling technology, which is applied in the direction of descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of complex structure of anti-scaling equipment, complicated installation process and low efficiency of anti-scaling , to save resources, high anti-scaling efficiency, and save electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be described in detail below with reference to the drawings and specific embodiments.

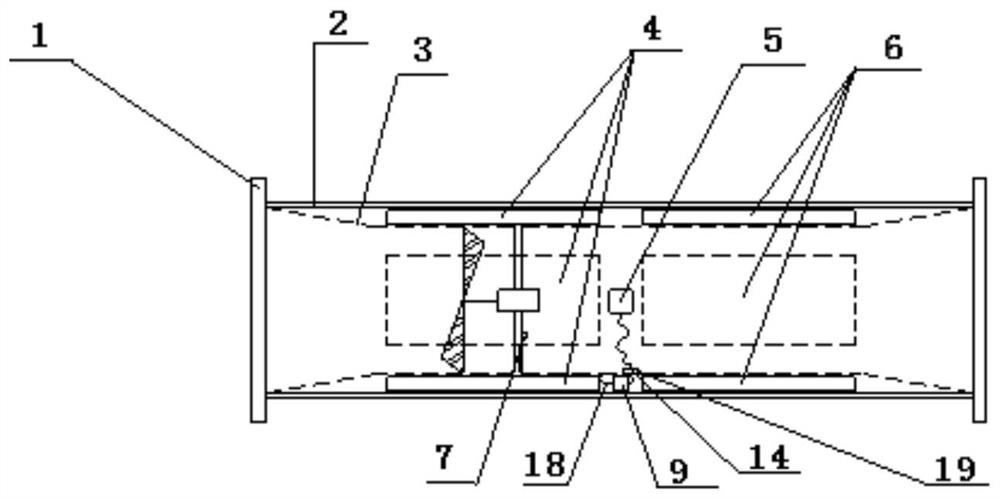

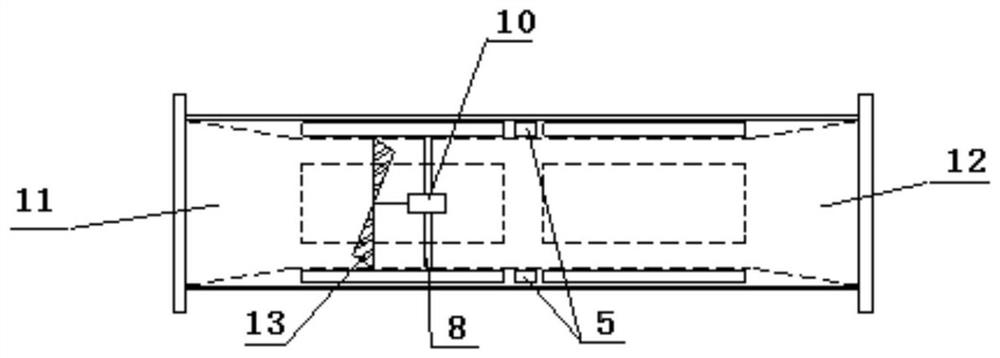

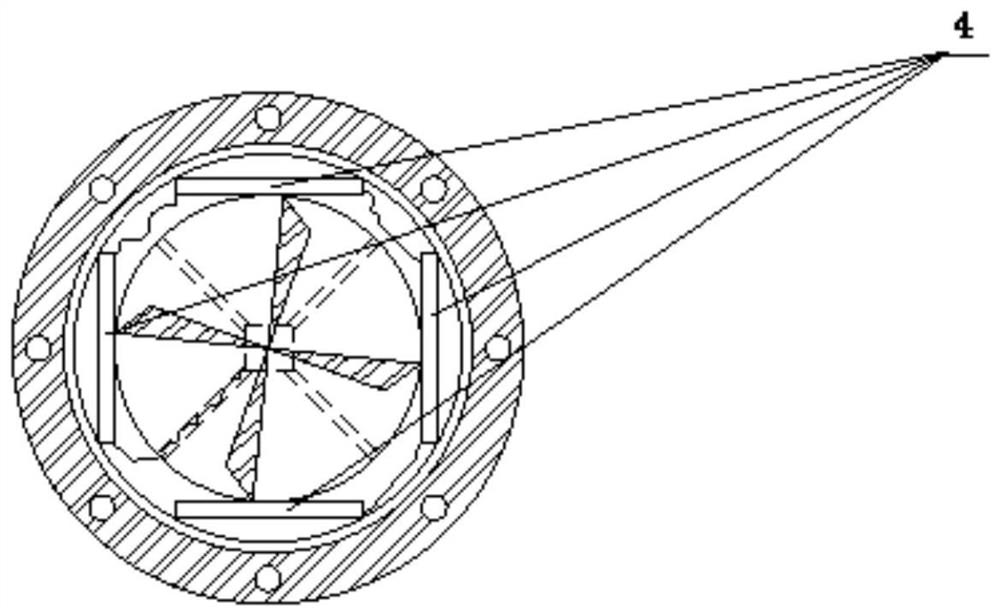

[0020]The scale inhibition equipment of the present invention includes a pair of flanges 1, an outer shell 2, an inner shell 3, an ultrasonic generator 5 and four permanent magnets 6. A pair of flanges 1 are respectively sleeved on both ends of the shell 2 for connecting with industrial water pipelines. The two ends of the outer shell 2 and the two ends of the inner shell 3 are respectively fixed together to form an annular closed space. The ultrasonic generator 5 and the four permanent magnets 6 are arranged in the annular enclosed space, and the ultrasonic generator 5 is connected to the power source through wires, and the four permanent magnets 6 are tangent to the outer wall of the inner shell 3. One end of the inner shell 3 is a water inlet 11 and the other end is a water outlet 12. It also includes a water flow detector 18, a water flow indicating switch 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com