Three-dimensional multilayer waveguide mode multiplexing and de-multiplexing device and preparation method thereof

A mode multiplexing, three-dimensional multi-layer technology, applied in the direction of optical waveguide light guide, light guide, instrument, etc., can solve the problems such as inability to directly couple, and achieve the goal of increasing device integration dimension, increasing integration degree, improving device integration degree and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing the three-dimensional waveguide mode multiplexer and demultiplexer, comprising the following steps:

[0052] Step 1: Take a piece of silicon substrate, treat the surface of the silicon wafer, and deposit a 2-3 μm silicon dioxide cladding layer on the surface of the silicon substrate by chemical vapor deposition (PECVD), which is the lower cladding layer. The reaction gas for the deposition of silicon dioxide is silane (SiH 4 ) and nitric oxide (N 2 O). During the deposition process, the temperature of the upper plate is 300°C, the temperature of the lower plate is 300°C, the power of the RF source is 700W, the cavity pressure is 300mTorr, N 2 O flow is 2000sccm, SiH 4 The flow rate is 17sccm,

[0053] Step 2: Carry out uniform photolithography on the lower cladding layer, and spread the photoresist on the surface of the chip at a low speed. The typical low speed speed is 1500-1750r / min, 3-5s; after that, the high speed volatilizes the photores...

Embodiment 1

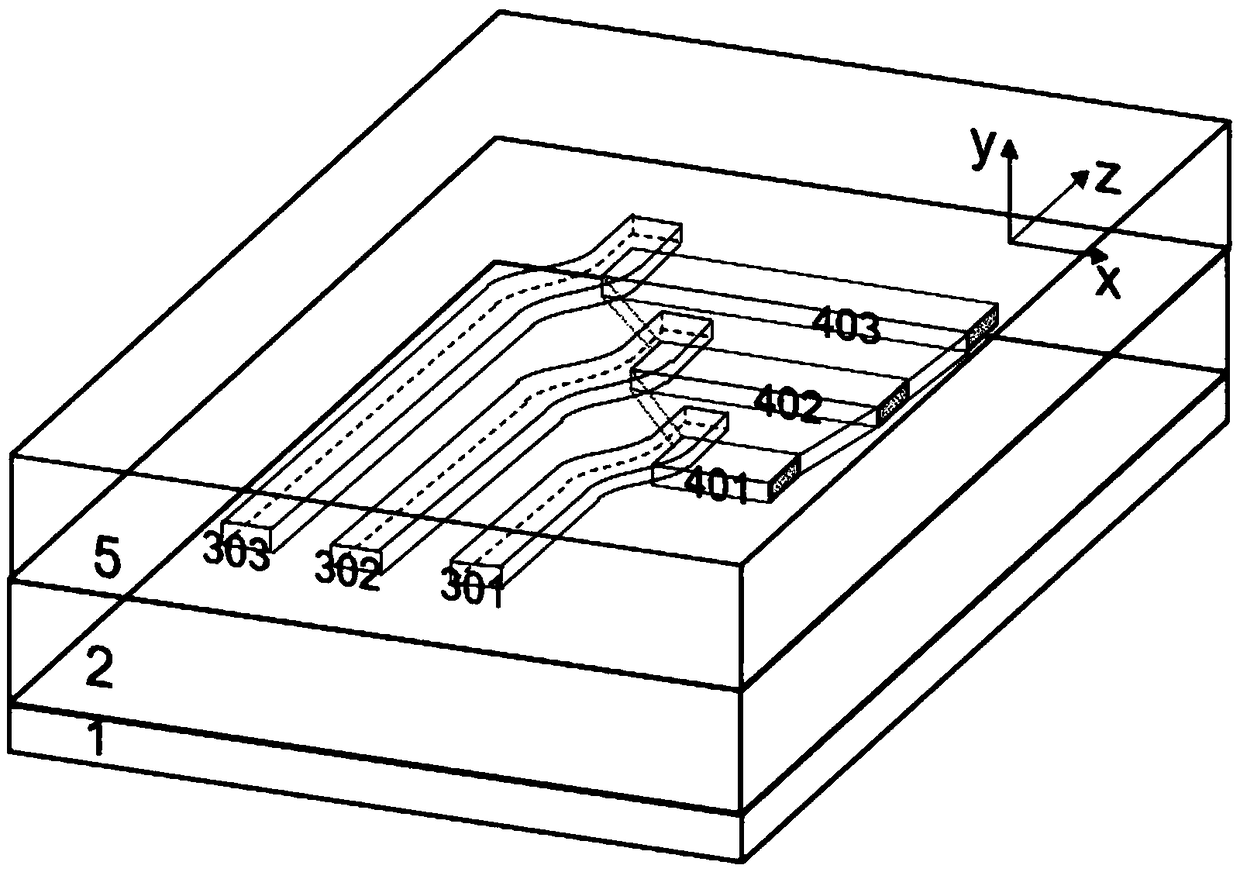

[0063] refer to figure 2 As shown, a three-dimensional multilayer waveguide mode multiplexer and demultiplexer includes a substrate layer 1, a lower cladding layer 2, an upper waveguide 3, a lower waveguide 4, an upper cladding layer 5 and an intermediate isolation layer 6.

[0064] figure 2 In the three-dimensional multi-layer waveguide mode multiplexer and demultiplexer shown, the lower layer waveguide 4 has a gradually changing width structure, including the first trunk waveguide section 401, the second trunk waveguide section 402 and the third trunk waveguide section 403, which can realize Multiplexing and demultiplexing of different high-order modes; the upper waveguide 3 includes a first input waveguide 301 , a second input waveguide 302 and a third input waveguide 303 .

[0065] Through the construction of a three-dimensional multilayer waveguide structure, compared with the traditional two-dimensional planar waveguide mode multiplexer and demultiplexer structure, th...

Embodiment 2

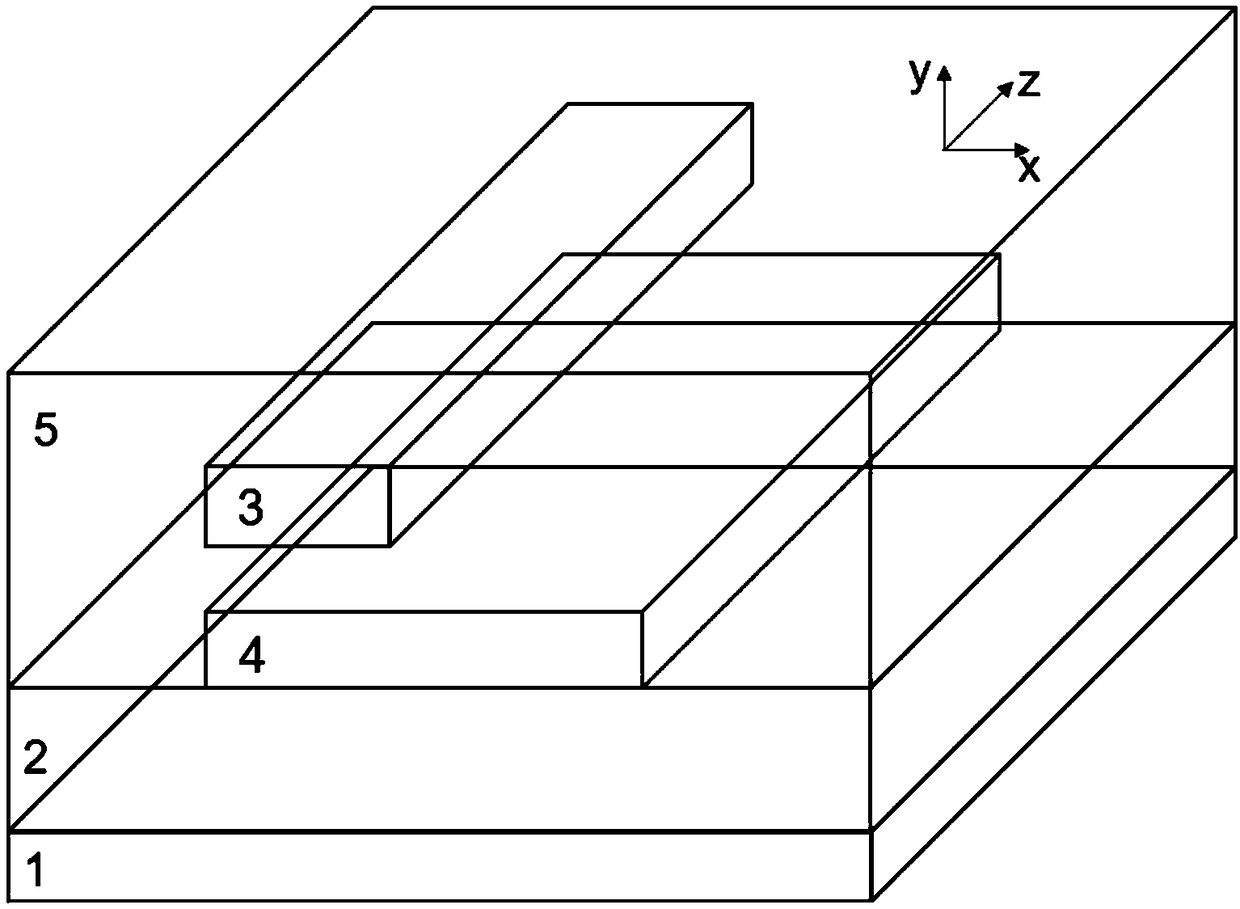

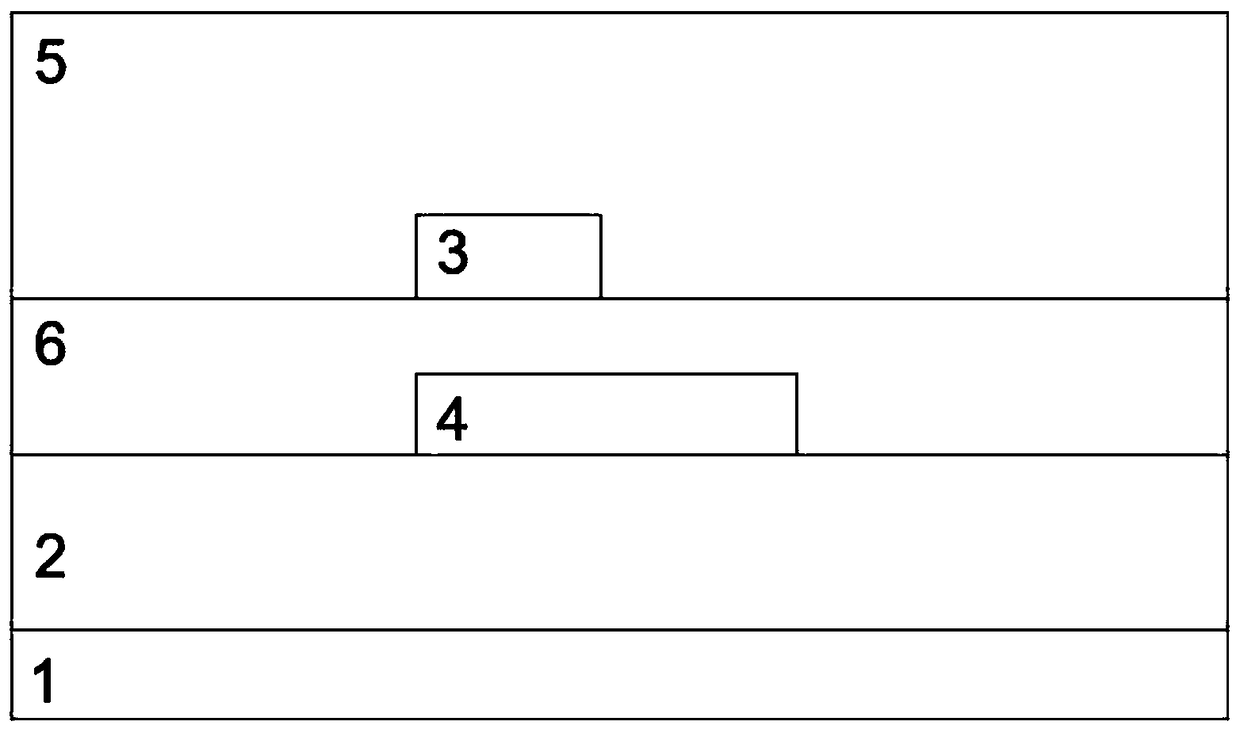

[0067] refer to image 3As shown, a three-dimensional multilayer waveguide retest multiplexer and demultiplexer includes a substrate layer 1, a lower cladding layer 2, an upper waveguide 3, a lower waveguide 4, an upper cladding layer 5 and an intermediate isolation layer 6.

[0068] image 3 The three-dimensional multi-layer waveguide single-mode multiplexer and demultiplexer shown is an example of analysis of a specific situation. In this structure, both the lower trunk waveguide and the upper layer input waveguide have only a section of structure, which belongs to the partial situation in the first embodiment. The specific analysis . The width h of the upper and lower waveguides is the same, both are 220nm, and the width of the lower waveguide w 1 =838nm, upper layer waveguide width w 2 =400nm, the gap between the upper and lower waveguides Gap=200nm. The upper layer waveguide 3 adopts a P-type silicon waveguide, and the lower layer waveguide 4 adopts a silicon waveguid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com