Reverse osmosis scale inhibitor and preparation method thereof

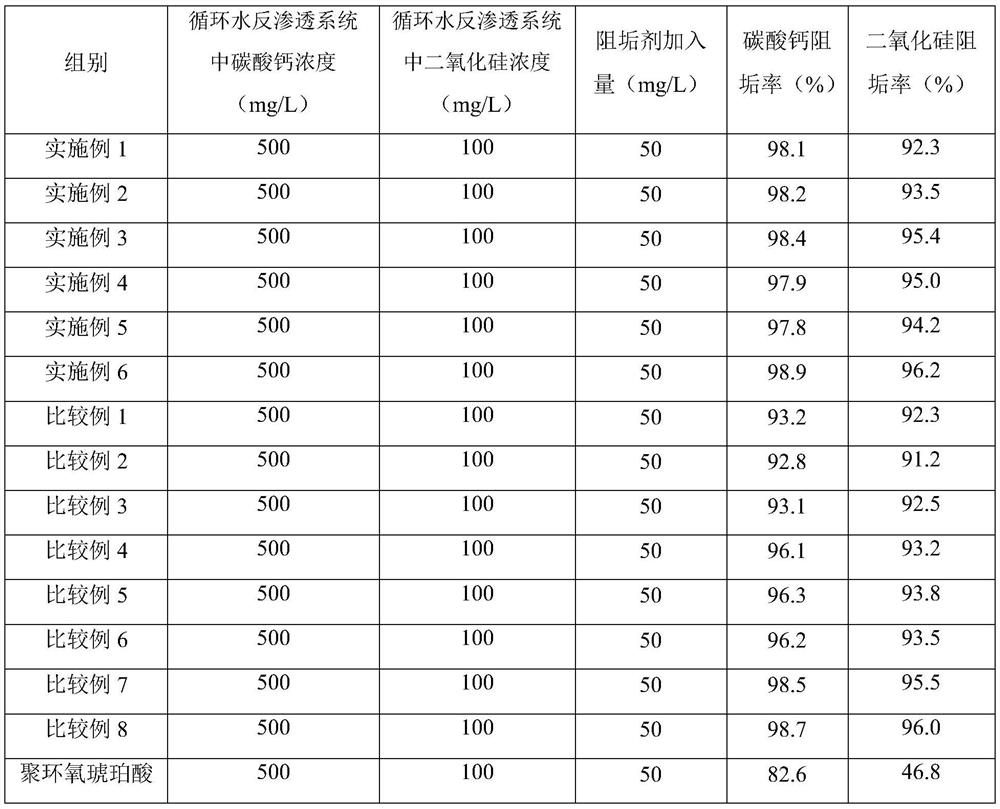

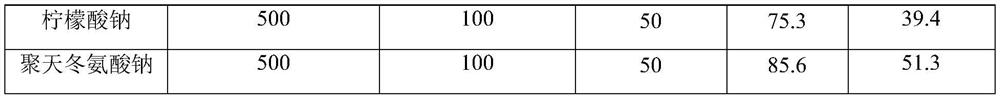

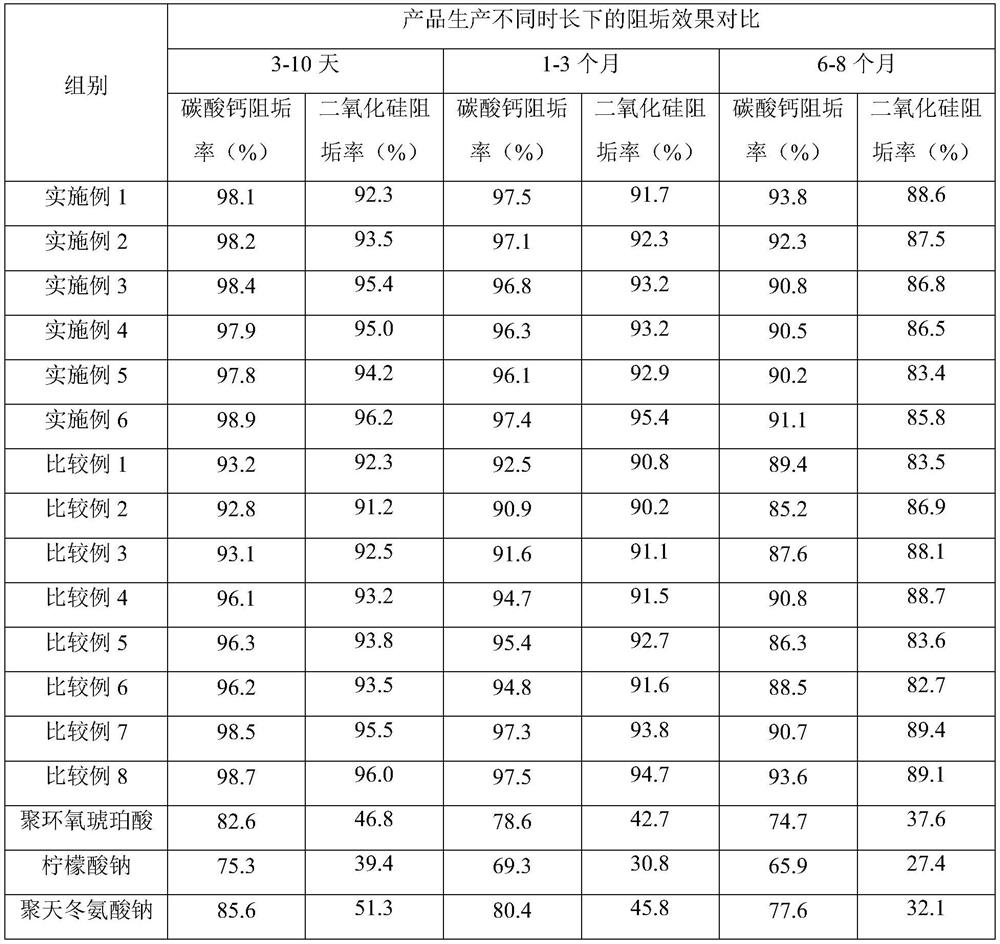

A scale inhibitor and reverse osmosis technology, applied in reverse osmosis, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve problems such as poor scale inhibition performance, membrane fouling, and single performance, and achieve excellent resistance The effect of silica scale performance, simple production process and excellent scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Weigh the following raw materials: 10g of sodium citrate, 15g of hydrolyzed polymaleic anhydride, 20g of polyepoxysuccinate, 10g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 1g of polylactic acid, deionized water 44g.

[0036] After the weighing is completed, pour sodium citrate, hydrolyzed polymaleic anhydride, polyepoxysuccinate and acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer into the reaction kettle for mixing, and add half of the deionized Water, at a temperature of 40°C, stir and dissolve for 2 hours until the liquid becomes viscous; at the same time, dissolve polylactic acid in half of deionized water to obtain a polylactic acid solution;

[0037] Then, the material prepared in the reactor was stirred at a temperature of 70°C, and the polylactic acid solution was added dropwise, and the flow rate was controlled. Store at heat preservation for 3 hours, and finally cool down the material in the reactor to 20°C to obtain t...

Embodiment 2

[0039] Weigh the following raw materials: sodium citrate 11g, hydrolyzed polymaleic anhydride 17g, polyepoxysuccinate 21g, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 12g, polylactic acid 2g, deionized water 37g.

[0040] After the weighing is completed, pour sodium citrate, hydrolyzed polymaleic anhydride, polyepoxysuccinate and acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer into the reaction kettle for mixing, and add half of the deionized Water, at a temperature of 45°C, stir and dissolve for 2 hours until the liquid becomes viscous; at the same time, dissolve polylactic acid in half of deionized water to obtain a polylactic acid solution;

[0041] Then, the material prepared in the reactor was stirred at a temperature of 70°C, and the polylactic acid solution was added dropwise, and the flow rate was controlled. Store at heat preservation for 3 hours, and finally cool down the material in the reactor to 20°C to obtain the reverse osm...

Embodiment 3

[0043] Weigh the following raw materials: 12g of sodium citrate, 20g of hydrolyzed polymaleic anhydride, 22g of polyepoxysuccinate, 13g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 3g of polylactic acid, deionized water 30g.

[0044] After the weighing is completed, pour sodium citrate, hydrolyzed polymaleic anhydride, polyepoxysuccinate and acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer into the reaction kettle for mixing, and add half of the deionized Water, at a temperature of 50°C, stir and dissolve for 2.5 hours until the liquid becomes viscous; at the same time, dissolve polylactic acid in half of deionized water to obtain a polylactic acid solution;

[0045] Then the materials prepared in the reactor were stirred at a temperature of 75°C, and the polylactic acid solution was added dropwise, the flow rate was controlled, and the dropping time was 5.5 hours; after the addition was completed, the stirring was continued for 1 hour, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com