A kind of membrane antiscalant and preparation method thereof

A scale inhibitor, room temperature technology, applied in the field of membrane scale inhibitor and its production, can solve the problems of increasing water supply pressure and cleaning frequency, affecting the normal operation of reverse osmosis device, decreasing water output or desalination rate, etc. The effect of less, stable nature and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

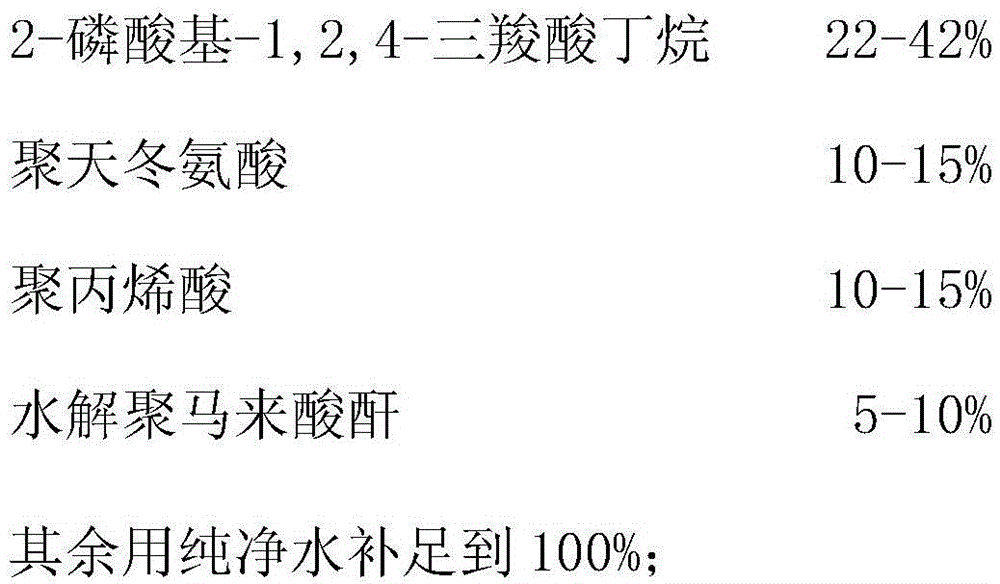

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: 100 kilograms of film antiscalants, are made up of the component of following weight: 2-phospho-1,2, 42 kilograms of 4-tricarboxylic acid butanes, 15 kilograms of polyaspartic acid, polyacrylic acid 15 kilograms, 10 kilograms of hydrolyzed polymaleic anhydride, all the other are pure water; The preparation steps are as follows:

[0033] Step 1: Add 2-phospho-1,2,4-tricarboxylic butane to the normal pressure reactor, and stir at normal temperature for 7 minutes;

[0034] Step 2: Add polyaspartic acid to the solution obtained in step 1, and stir at room temperature for 10 minutes;

[0035] Step 3: Add polyacrylic acid to the solution obtained in step 2, and stir at room temperature for 10 minutes;

[0036] Step 4: Add hydrolyzed polymaleic anhydride to the solution obtained in step 3, and stir at room temperature for 5 minutes;

[0037] Step 5, add pure water to the solution obtained in step 4, and stir at room temperature for 20 minutes to obtain a membra...

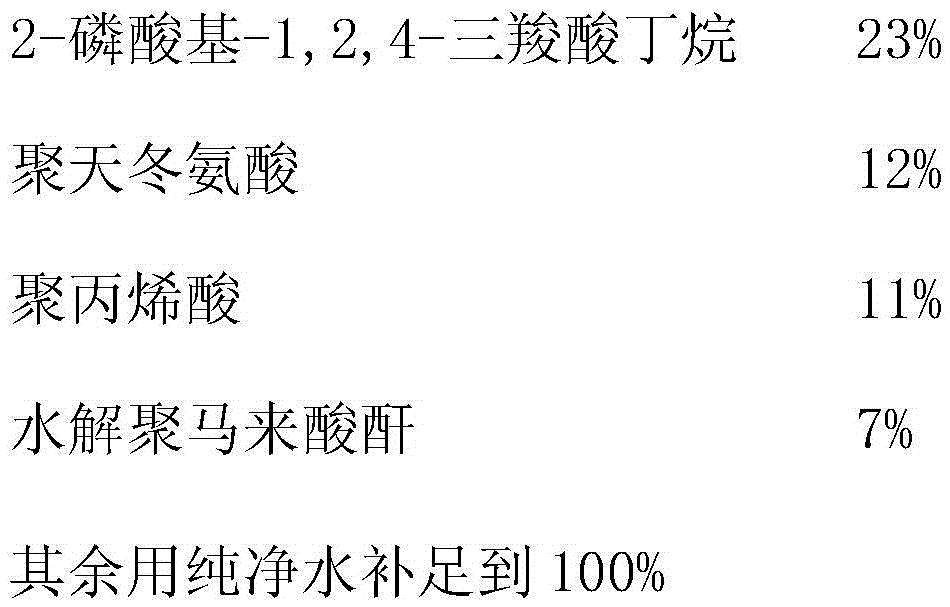

Embodiment 2

[0049] Embodiment 2: 100 kilograms of membrane antiscalants, are made up of the component of following weight: 2-phospho-1,2,22 kilograms of 4-tricarboxylic acid butanes, 10 kilograms of polyaspartic acid, polyacrylic acid 10 kilograms, 5 kilograms of hydrolyzed polymaleic anhydride, all the other are pure water; The preparation steps are as follows:

[0050] Step 1: Add 2-phospho-1,2,4-tricarboxylic acid butane into the normal pressure reactor, and stir at normal temperature for 5-7 minutes;

[0051] Step 2: Add polyaspartic acid to the solution obtained in step 1, and stir at room temperature for 8 minutes;

[0052] Step 3: Add polyacrylic acid to the solution obtained in step 2, and stir for 7 minutes at room temperature;

[0053] Step 4: Add hydrolyzed polymaleic anhydride to the solution obtained in step 3, and stir at room temperature for 3 minutes;

[0054] Step 5, add pure water to the solution obtained in step 4, and stir at room temperature for 15 minutes to obtain...

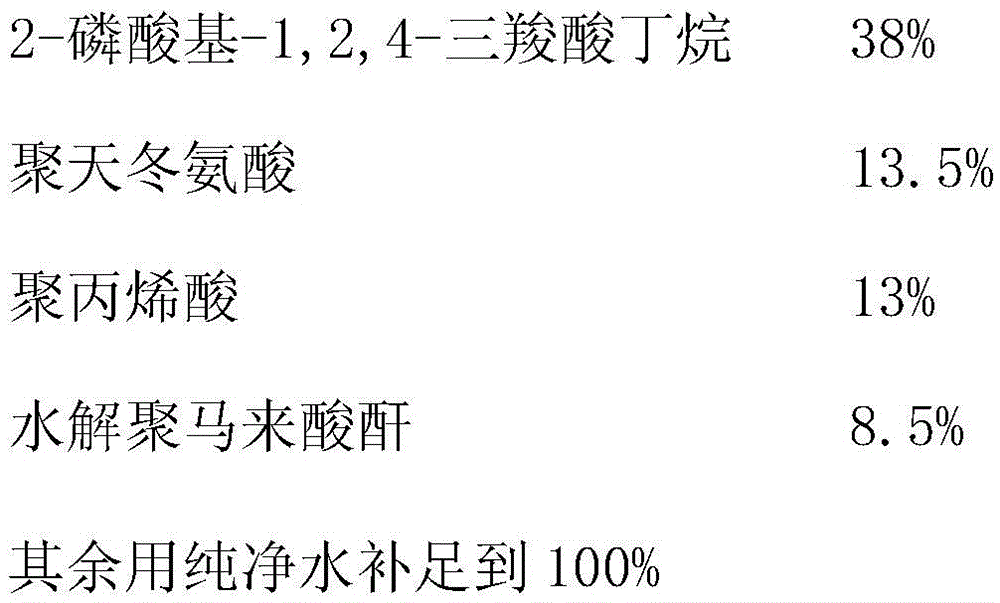

Embodiment 3

[0066] Embodiment 3: 100 kilograms of film antiscalants, are made up of the component of following weight: 2-phospho-1,2, 32 kilograms of 4-tricarboxylic acid butanes, 12.5 kilograms of polyaspartic acid, polyacrylic acid 12.5 kilograms, 7.5 kilograms of hydrolyzed polymaleic anhydride, all the other are pure water; The preparation steps are as follows:

[0067] Step 1: Add 2-phospho-1,2,4-tricarboxylic acid butane into the normal pressure reactor, and stir at normal temperature for 5-7 minutes;

[0068] Step 2: Add polyaspartic acid to the solution obtained in step 1, and stir at room temperature for 9 minutes;

[0069] Step 3: Add polyacrylic acid to the solution obtained in step 2, and stir at room temperature for 8 minutes;

[0070] Step 4: Add hydrolyzed polymaleic anhydride to the solution obtained in step 3, and stir at room temperature for 4 minutes;

[0071] Step 5, add pure water to the solution obtained in step 4, and stir at room temperature for 17 minutes to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com