Scale and corrosion inhibitor for oil field system

A scale and corrosion inhibitor, oilfield technology, applied in the field of water treatment, can solve problems such as secondary pollution of oilfield water, achieve high scale inhibition efficiency, improve scale and corrosion inhibition effect, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

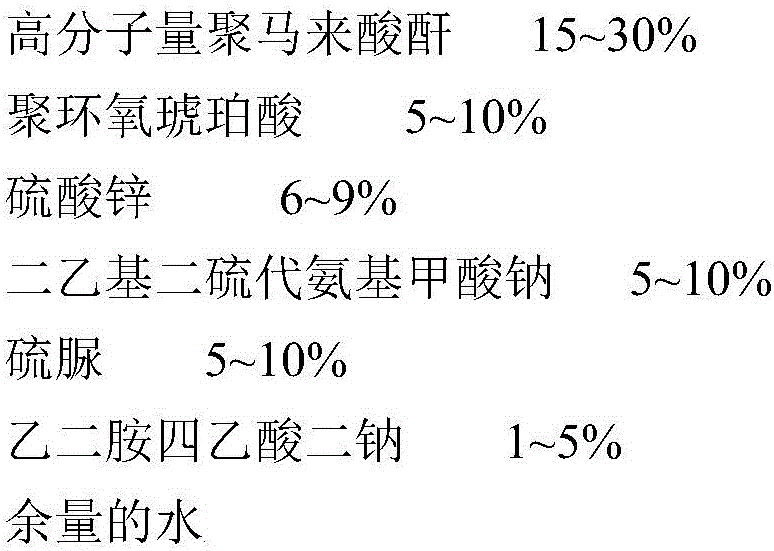

[0028] Embodiment 1: a kind of antiscaling and corrosion inhibitor for oil field system, its batching weight percentage is composed of:

[0029]

[0030] Wherein, the average molecular weight of the high molecular weight polymaleic anhydride is greater than 6000; the polyepoxysuccinic acid is an aqueous solution of polyepoxysuccinic acid with a mass fraction of 46%.

[0031] The steps of the preparation method of the present invention are:

[0032] (1) adding solid polymaleic anhydride and water into the reactor at room temperature and stirring for 20 to 30 minutes to fully hydrolyze the solid polymaleic anhydride;

[0033] (2) Put zinc sulfate, sodium diethyldithiocarbamate, thiourea, and disodium ethylenediaminetetraacetate in sequence in the reaction kettle, and stir for 20 to 30 minutes to fully dissolve the ingredients;

[0034] (3) Finally, polyepoxysuccinic acid is added into the reaction kettle, and the product is obtained after stirring evenly.

Embodiment 2

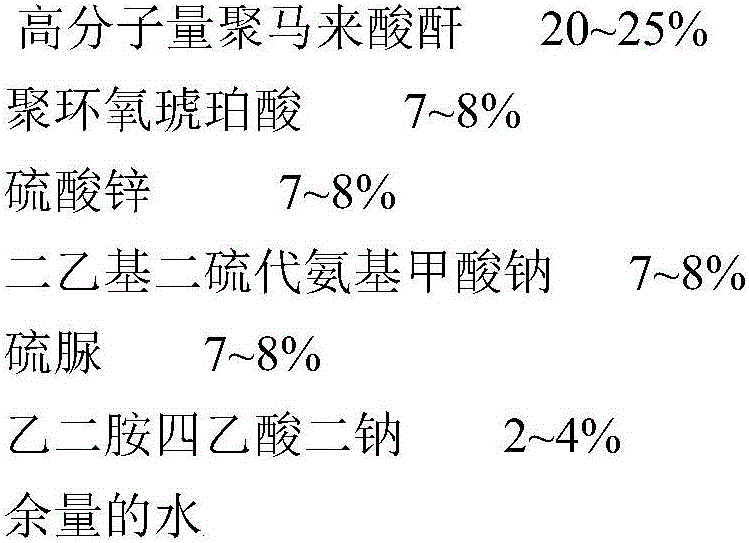

[0035] Embodiment 2: a kind of antiscaling and corrosion inhibitor for oil field system, its batching weight percentage is composed of:

[0036]

[0037] Wherein, the average molecular weight of the high molecular weight polymaleic anhydride is greater than 6000; the polyepoxysuccinic acid is an aqueous solution of polyepoxysuccinic acid with a mass fraction of 46%.

[0038] The steps of the preparation method of this embodiment are the same as those in Example 1.

Embodiment 3

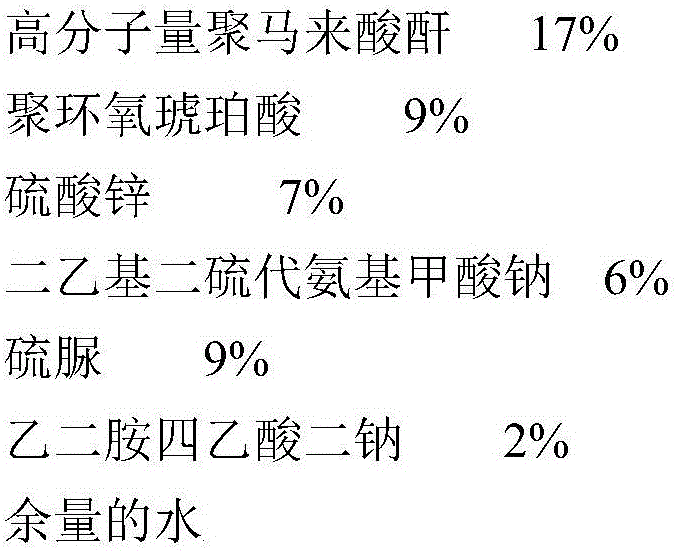

[0039] Embodiment 3: a kind of antiscaling and corrosion inhibitor for oil field system, its batching weight percentage is composed of:

[0040]

[0041] Wherein, the average molecular weight of the high molecular weight polymaleic anhydride is greater than 6000; the polyepoxysuccinic acid is an aqueous solution of polyepoxysuccinic acid with a mass fraction of 46%.

[0042] The steps of the preparation method of this embodiment are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com