Scale inhibitor for industrial circulating cooling water

A technology of circulating cooling water and scale inhibition, which is applied in the field of scale inhibitors to achieve the effects of strong alkali resistance, high efficiency of scale inhibition and high efficiency of scale inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

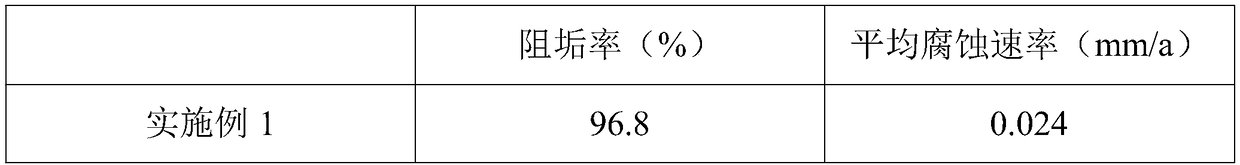

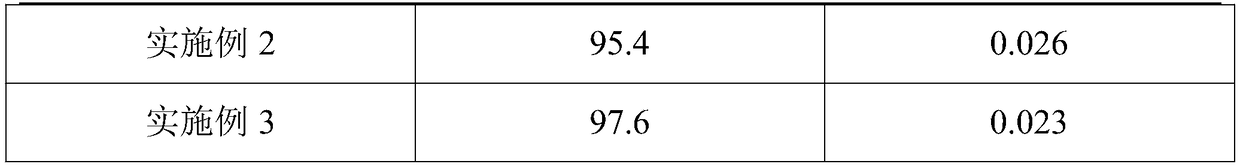

Examples

Embodiment 1

[0022] A preparation method of modified polyaspartic acid, comprising the following steps:

[0023] 1) Configuration of maleic anhydride aqueous solution: after dissolving urea in water, add dropwise to the aqueous solution of maleic anhydride, then carry out amination hydrolysis reaction at 108 ° C, cool to room temperature, then add sodium hydrogen sulfate catalyst, in the mixture of sulfuric acid and hydrochloric acid. In the mixed acid solvent, the polysuccinimide is obtained by reacting under vacuum conditions at 125 °C; the volume ratio of the sulfuric acid to the hydrochloric acid in the mixed acid solvent is 1.2:1; the concentration of the sulfuric acid is 12 mol / L, and the The concentration of hydrochloric acid is 7mol / L

[0024] 2) After the polysuccinimide was taken out and cooled, dimethyl sulfoxide was used as solvent, lignin sulfonic acid and oxalic acid were added to react in an oil bath at 105°C for 2 hours, cooled, and alkali was added to adjust the pH to 9, a...

Embodiment 2

[0026] A preparation method of modified polyaspartic acid, comprising the following steps:

[0027] 1) Configuration of maleic anhydride aqueous solution: after dissolving urea in water, add dropwise to the aqueous solution of maleic anhydride, then carry out amination hydrolysis reaction at 106 ° C, cool to room temperature, then add sodium hydrogen sulfate catalyst, in the mixture of sulfuric acid and hydrochloric acid. In the mixed acid solvent, the polysuccinimide is obtained by reacting under 135 ℃ of vacuum conditions; the volume ratio of the sulfuric acid and the hydrochloric acid in the mixed acid solvent is 1:1; the concentration of the sulfuric acid is 10 mol / L, and the concentration of the hydrochloric acid is 8mol / L.

[0028] 2) After taking out the polysuccinimide for cooling, using dimethyl sulfoxide as solvent, adding lignosulfonic acid and oxalic acid in an oil bath at 100°C for 2.5 hours, cooling, and adding alkali to adjust pH to 8, 40°C Hydrolyzed for 50 mi...

Embodiment 3

[0030] A preparation method of modified polyaspartic acid, comprising the following steps:

[0031] 1) Configuration of maleic anhydride aqueous solution: after dissolving urea in water, add dropwise to the aqueous solution of maleic anhydride, then carry out amination hydrolysis reaction at 110 ° C, cool to room temperature, then add sodium hydrogen sulfate catalyst, in the mixture of sulfuric acid and hydrochloric acid. In the mixed acid solvent, the polysuccinimide is obtained by reacting under 120 ℃ of vacuum conditions; the volume ratio of the sulfuric acid and the hydrochloric acid in the mixed acid solvent is 1.5:1; the concentration of the sulfuric acid is 15 mol / L, and the concentration of the hydrochloric acid is 5mol / L.

[0032] 2) After taking out the polysuccinimide for cooling, using dimethyl sulfoxide as solvent, adding lignin sulfonic acid and oxalic acid in an oil bath at 110 °C for 1.5 hours, cooling, and adding alkali to adjust the pH to 10,60 °C Hydrolyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com