Scale inhibitor of refining equipment

A scale inhibitor and equipment technology, applied in the field of hydrocarbon oil cracking, can solve the problems of poor high temperature resistance, reduced decomposition and use effect of cleaning and dispersant, single function of scale inhibitor components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0036] Polyisobutylene succinimide p-methoxy phenolic condensate 80g

[0037] N,N'-Dihydric ylidene-1,2-propanediamine 8g

[0038] Calcium Alkyl Salicylate 12g

[0039] Heavy aromatics 20g

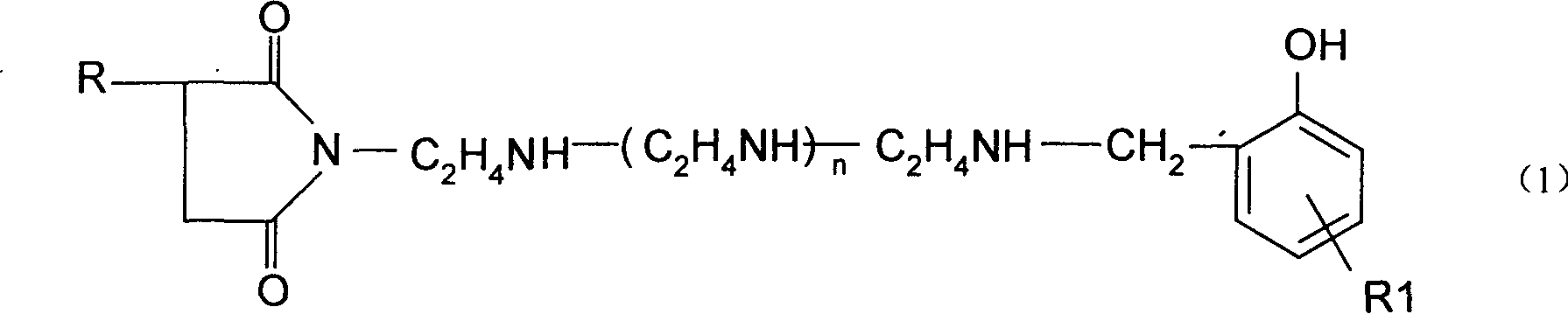

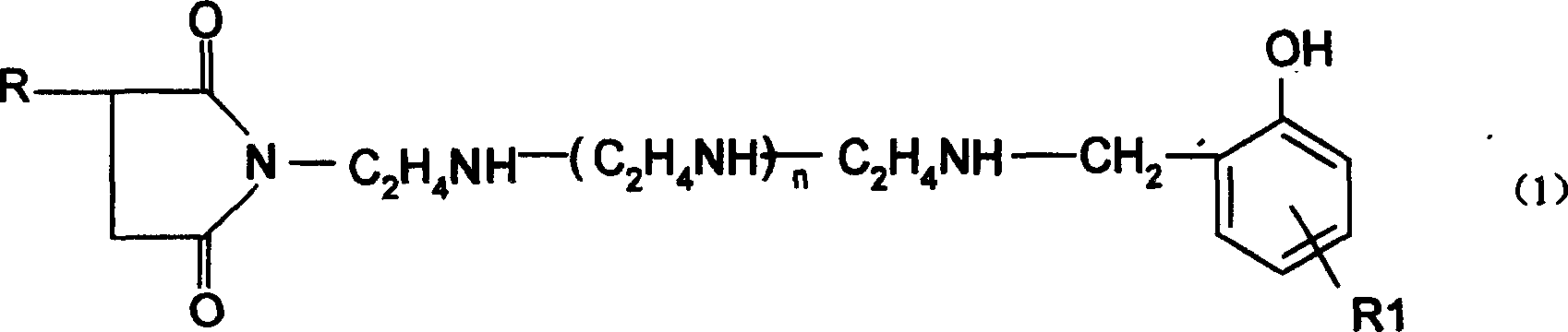

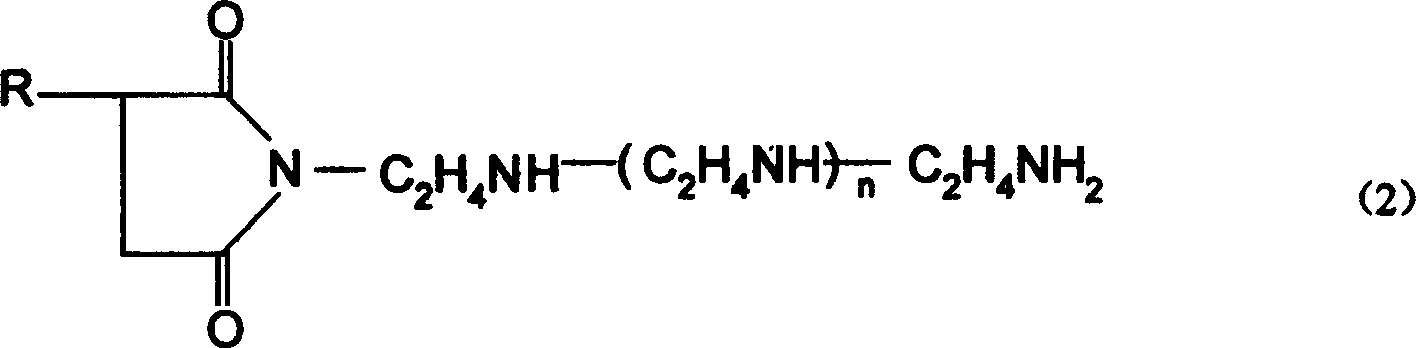

[0040] In the structural formula (1), R is a polyisobutenyl group, and the molecular weight is 1000, and R 1 for C 1 The p-methoxyphenol, n is 0.

[0041] Its preparation method is as follows:

[0042] Add polyisobutylene succinimide p-methoxyphenol aldehyde condensate, N,N'-dihydric ylidene-1,2-propylenediamine, calcium alkyl salicylate and heavy aromatics into the flask according to the above ratio Mix, heat to 60-70°C, and stir for 30-60 minutes to obtain the product of the present invention.

Embodiment 2

[0044] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0045] Polyisobutylene succinimide p-methoxy phenolic condensate 60g

[0046] N,N'-Dihydric ylidene-1,2-propanediamine 15g

[0047] Calcium Alkyl Salicylate 25g

[0048] Heavy aromatics 20g

[0049] In the structural formula (1), R is a polyisobutenyl group, and the molecular weight is 1000, and R 1 for C 1 The p-methoxyphenol, n is 0.

[0050] Its preparation method is identical with embodiment 1.

Embodiment 3

[0052] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0053] Polyisobutylene succinimide p-methoxyphenol aldehyde condensate 94g

[0054] N,N'-Dihydric ylidene-1,2-propanediamine 1g

[0055] Calcium Alkyl Salicylate 5g

[0056] Heavy aromatics 20g

[0057] In the structural formula (1), R is a polyisobutenyl group, and the molecular weight is 1000, and R 1 for C 1 The p-methoxyphenol, n is 0.

[0058] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com