Scale inhibitor specially used for seawater circulating cooling water

A technology of circulating cooling water and antiscalant, which is applied in the field of antiscalant and can solve problems such as prominent scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Scale inhibitor composition: polyacrylic acid 25%; methyl acrylate 30%; hydrolyzed polymaleic anhydride 20%; polyaspartic acid 15%; 2-epoxypropyl dodecyl dimethyl quaternary ammonium salt 10%.

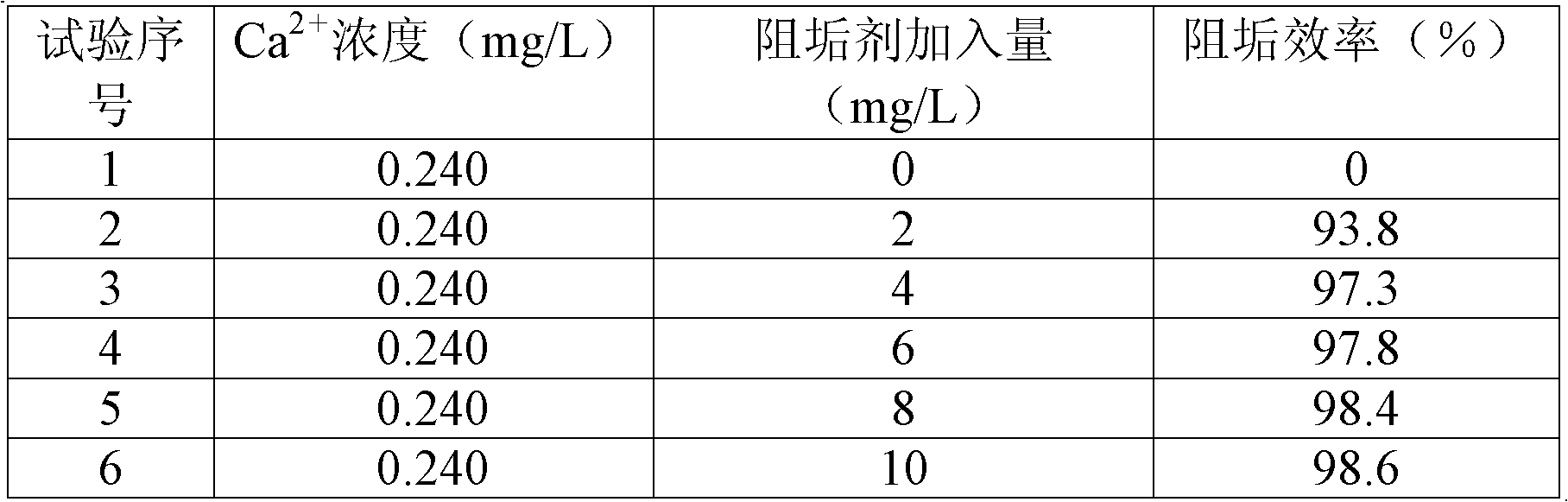

[0016] 2) Purpose of the test: to evaluate the scale inhibition performance of the scale inhibitors through the static calcium carbonate deposition test.

[0017] 3) Test solution: simulated circulating water preparation (Ca 2+ Concentration is ρ 1 ).

[0018] 4) Test method:

[0019] Refer to "GB / T16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Performance of Water Treatment Agents".

[0020] Add different doses of antiscalant to each prepared simulated circulating water, and leave a blank sample at the same time. Immerse these samples in a constant temperature water bath at about 80°C (the liquid level of the test solution should not be higher than that of the water bath), and keep the temperature constant for 10 hours. After cooli...

Embodiment 2

[0031] 1) Scale inhibitor composition: polyacrylic acid 20%; ethyl acrylate 25%; hydrolyzed polymaleic anhydride 30%; polyaspartic acid 20%; 2-epoxypropyl dodecyl dimethyl quaternary ammonium salt 5%.

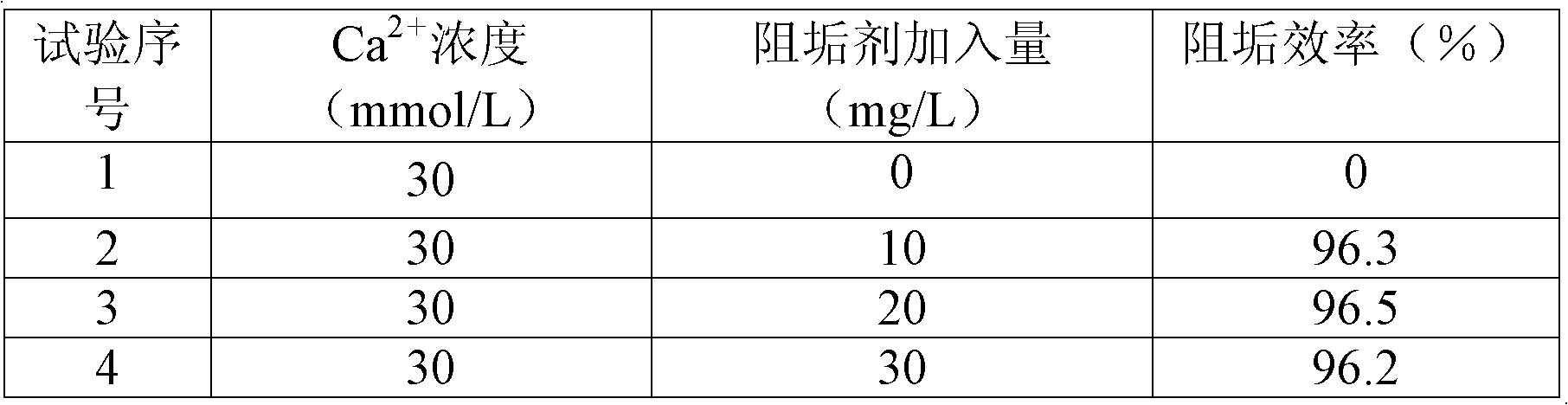

[0032] 2) Purpose of the test: to evaluate the scale inhibition performance of the scale inhibitors through the static calcium carbonate deposition test.

[0033] 3) Test solution: simulated seawater circulating water preparation (Ca 2+ Concentration is ρ 1 ).

[0034] 4) Test method:

[0035] See Example 1.

[0036] 5) Analysis and expression of test results:

[0037] The relative scale inhibition performance (N) of the water treatment agent expressed as a percentage is calculated according to the following formula:

[0038] N=(ρ 2 -ρ 3 ) / (ρ 1 -ρ 3 )×100%

[0039] where ρ 1 ——Calcium ions (Ca 2+ ) concentration, mg / mL;

[0040] ρ 2 ——Calcium ions (Ca 2+ ) concentration, mg / mL;

[0041] ρ 3 — Calcium ions (Ca 2+ ) concentration, mg / mL.

[0042] 6) Test recor...

Embodiment 3

[0046] Scale inhibitor composition: polyacrylic acid 25%; butyl acrylate 30%; hydrolyzed polymaleic anhydride 15%; polyaspartic acid 15%; 2-epoxypropyl dodecyl dimethyl quaternary ammonium salt 15% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com