Phosphorus-free scale and corrosion inhibitor and preparation method thereof

A phosphorus-free scale and corrosion inhibitor technology, applied in chemical instruments and methods, descaling and water softening, natural water treatment, etc., can solve problems such as environmental pollution, improve scale inhibition efficiency, reduce scale deposition, The effect of reducing the content of phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

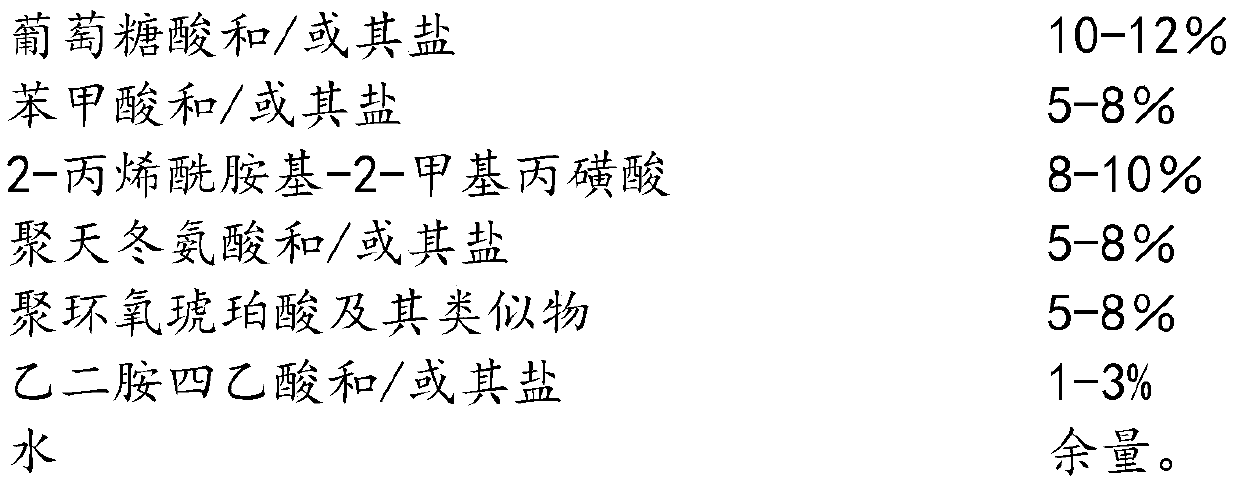

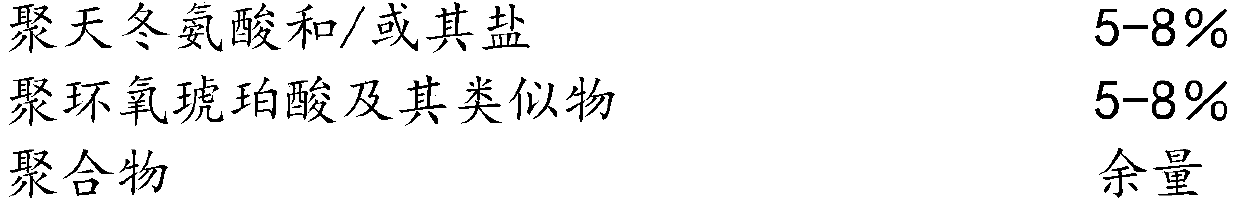

Embodiment 1

[0024] The composite non-phosphorus scale and corrosion inhibitor provided in this example is formed by mixing and stirring the following raw materials in mass percentage at room temperature: 10% sodium gluconate, 8% sodium benzoate, 2-acrylamido-2-methylpropane 10% sulfonic acid, 5% polyaspartic acid, 8% polyepoxysuccinic acid, 3% diaminetetraacetic acid, and the rest is ultrapure water.

[0025] The method of use is: the dosage of the product after synthesis is 20-100ppm.

[0026] experiment method:

[0027] (A) The circulating cooling water of the test object is divided into multiple parts;

[0028] (B) get the composite non-phosphorus scale and corrosion inhibitor of the present embodiment, dosing 20ppm (B1), 50ppm (B2), 100ppm (B3) process the circulating cooling water in A;

[0029] (C) Get the treatment agent of commercially available polyphosphoric acid class, dosage 20ppm (C1), 50ppm (C2), 100ppm (C3), process the circulating cooling water in A;

[0030] (D) Get th...

Embodiment 2

[0036] The composite non-phosphorus scale and corrosion inhibitor provided in this example is formed by mixing and stirring the following raw materials in mass percentage at room temperature: 12% sodium gluconate, 5% sodium benzoate, 2-acrylamido-2-methylpropane 8% sulfonic acid, 5% polyaspartic acid, 8% polyepoxysuccinic acid, 1% diaminetetraacetic acid, and the rest is ultrapure water. A good long-term scale inhibition effect can be achieved when the dosage is 20-100ppm.

Embodiment 3

[0038] The composite non-phosphorus scale and corrosion inhibitor provided in this example is formed by mixing and stirring the following raw materials in mass percentage at room temperature: 10% sodium gluconate, 7% sodium benzoate, 2-acrylamido-2-methylpropane 8% sulfonic acid, 7% sodium polyaspartate, 8% polyepoxysuccinic acid, 1% tetrasodium diaminetetraacetic acid, and the rest is ultrapure water. A good long-term scale inhibition effect can be achieved when the dosage is 20-100ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com