Boiler pre-filming corrosion and scale inhibitor

A technology of pre-film corrosion and scale inhibitors, which is applied in the field of boiler pre-film corrosion and scale inhibitors, can solve problems such as poor thermal conductivity, corrosion of boiler feed water, and reduced thermal conductivity, so as to achieve sustainable development and prevent corrosion Effects on fouling and excellent heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

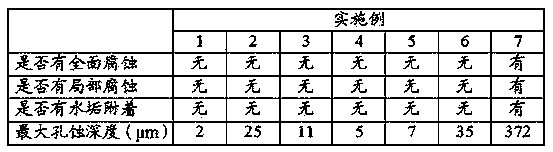

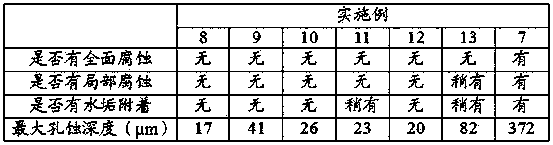

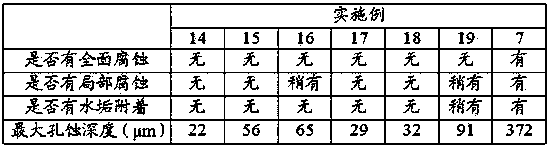

Examples

Embodiment 1

[0012] A boiler pre-film corrosion and scale inhibitor is provided, which is composed of: 9g of zinc sulfate, 3g of sodium sulfite, 5g of sodium polyepoxysuccinate, 8g of sodium hydroxide, and 75g of water.

Embodiment 2

[0014] A boiler pre-film corrosion and scale inhibitor is provided, which is composed of: 3.5g of zinc sulfate, 3g of sodium sulfite, 5g of sodium polyepoxysuccinate, 8g of sodium hydroxide, and 80.5g of water.

Embodiment 3

[0016] A boiler pre-film corrosion and scale inhibitor is provided, which is composed of: 9g of zinc sulfate, 1g of sodium sulfite, 5g of sodium polyepoxysuccinate, 8g of sodium hydroxide, and 77g of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com