Polyimide composite coating and preparation method thereof and application thereof

A polyimide and composite coating technology, applied in coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of unsuitable on-site construction and cumbersome procedures, and achieve low cost, simple process, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

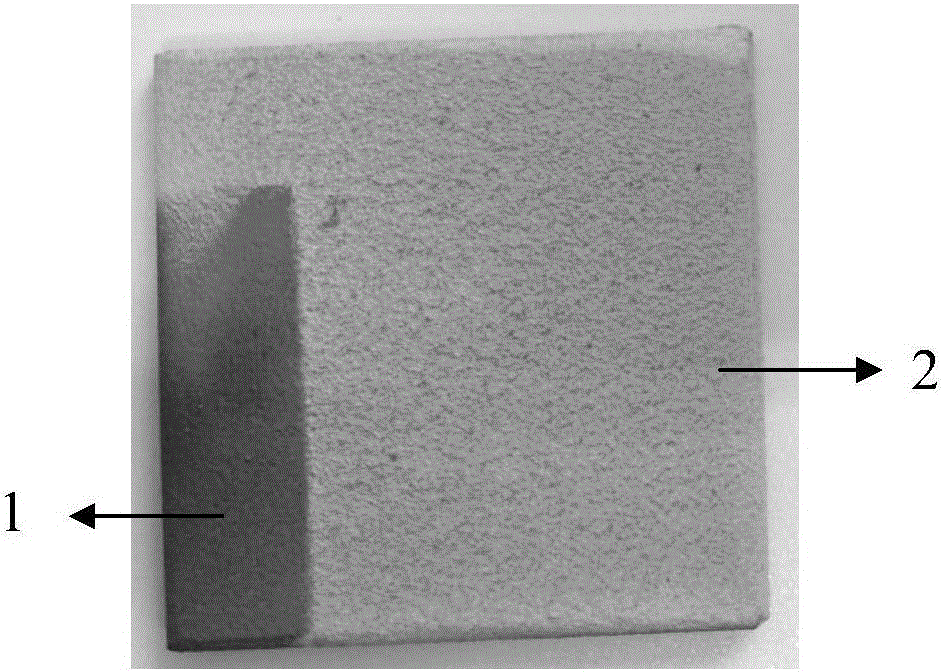

[0080] In the following three examples, the substrate material is a composite coating of PI / flake graphite (mass ratio 10%, 20%, 30%) deposited on the surface of a Q235 steel sheet with a thickness of about 2 mm, and the thickness of the coating is ~ 100 μm. The material is well combined; the specific preparation method of the PI / graphite composite coating is as follows:

[0081] 1. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 200ml of N,N-dimethylformamide (DMF), stir to dissolve it completely (5min); then weigh Take 10.906g of pyromellitic dianhydride (PMDA), add a small amount of multiple times to the above solution and stir; continue to stir for 8 to 10 hours after the addition is complete to obtain a polyimide precursor polyamic acid solution;

[0082] 2. Add the additive - flake graphite (size is 20 μm) to the polyamic acid solution, the mass fraction of flake graphite is 10%, 20%, 30% respectively, and ultrasonically stir for 1 to 2 hours to finally...

Embodiment 4~6

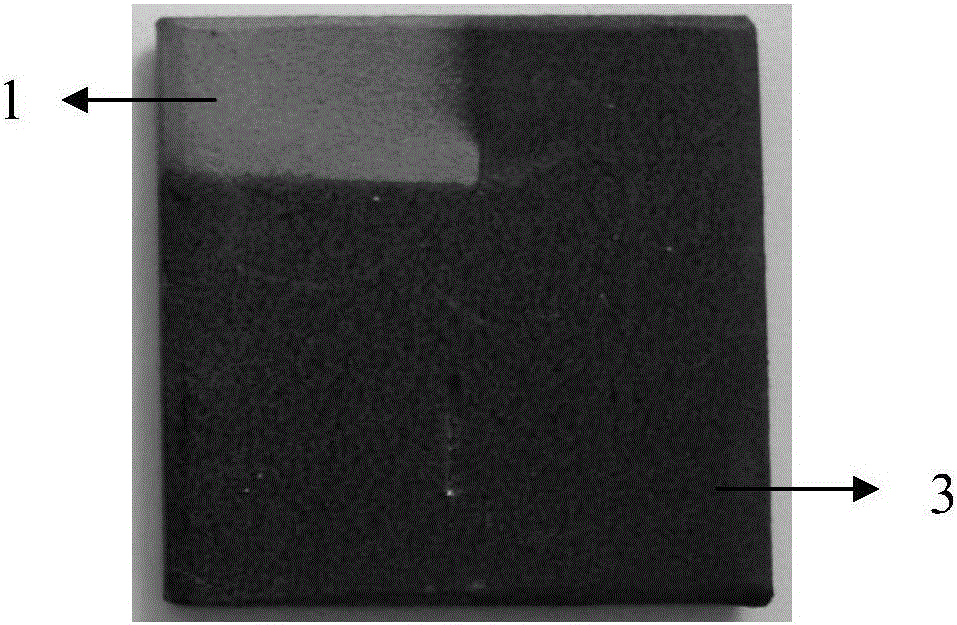

[0090] In the following three examples, the substrate material is a 316 stainless steel sheet with a thickness of about 2 mm, and the surface deposits PI / nanometer Cu (mass ratio 10%, 20%, 30%) composite coating, and the thickness of the coating is ~ 20 μm, and the coating and the substrate The material is well combined; the specific preparation method of the PI / Cu composite coating is as follows:

[0091] 1. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 200ml of N,N-dimethylformamide (DMF), stir to dissolve it completely (5min); then weigh Take 10.906g of pyromellitic dianhydride (PMDA), add a small amount of multiple times to the above solution and stir; continue to stir for 8 to 10 hours after the addition is complete to obtain a polyimide precursor polyamic acid solution;

[0092] 2. Add additive-nano-copper (particle size: 300nm) to the polyamic acid solution, the mass fraction of nano-copper is 10%, 20%, 30% respectively, and ultrasonically stir for 1-2...

Embodiment 7~9

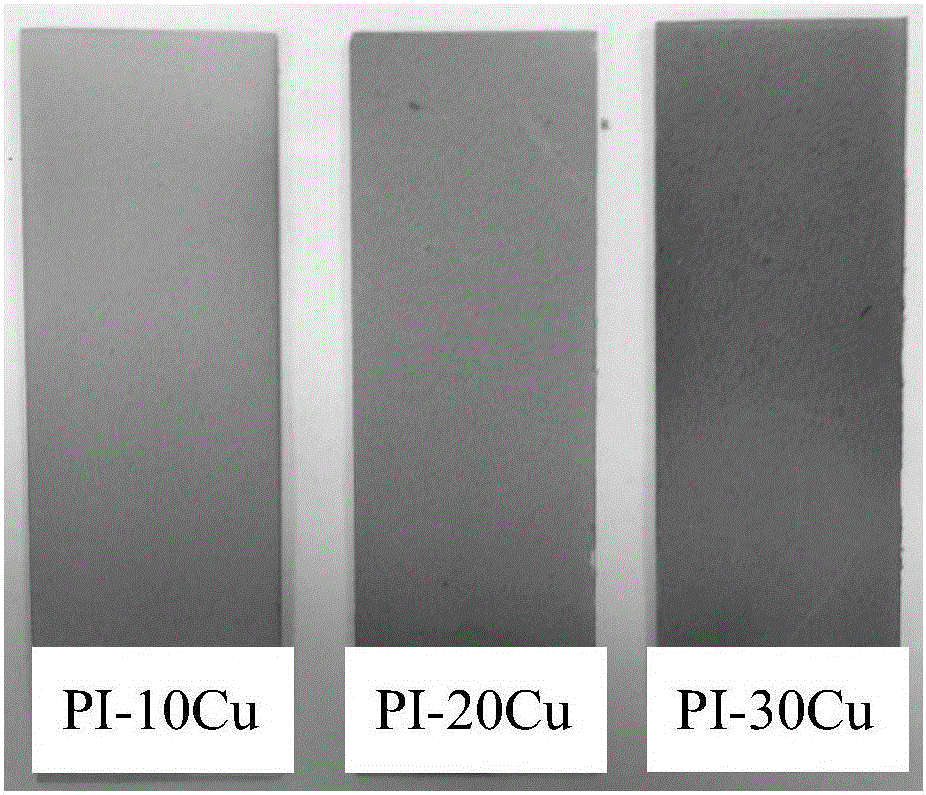

[0100] In this embodiment, the substrate material is a PI / micron Cu (mass ratio of 10%, 20%, 30%) composite coating deposited on the surface of a Q345 steel sheet with a thickness of about 1.5 mm, and the thickness of the coating is ~ 200 μm. The coating and the substrate material Combine well; The specific preparation method of this PI / micron Cu composite coating is as follows:

[0101] 1. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 200ml of N,N-dimethylformamide (DMF), stir to dissolve it completely (5min); then weigh Take 10.906g of pyromellitic dianhydride (PMDA), add a small amount of multiple times to the above solution and stir; continue to stir for 8 to 10 hours after the addition is complete to obtain a polyimide precursor polyamic acid solution;

[0102] 2. Add additive-micron copper (particle size: 200 mesh) to the polyamic acid solution, the mass fraction of micron copper is 10%, 20%, and 30% respectively, ultrasonically and stirred for 1-2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com