Cartilage cell removal matrix and preparation method and application thereof

A decellularized matrix and chondrocyte technology, applied in the field of decellularized cartilage matrix and its preparation, can solve the problems of difficult growth of new cells, incomplete decellularization, and difficulty in making specific shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

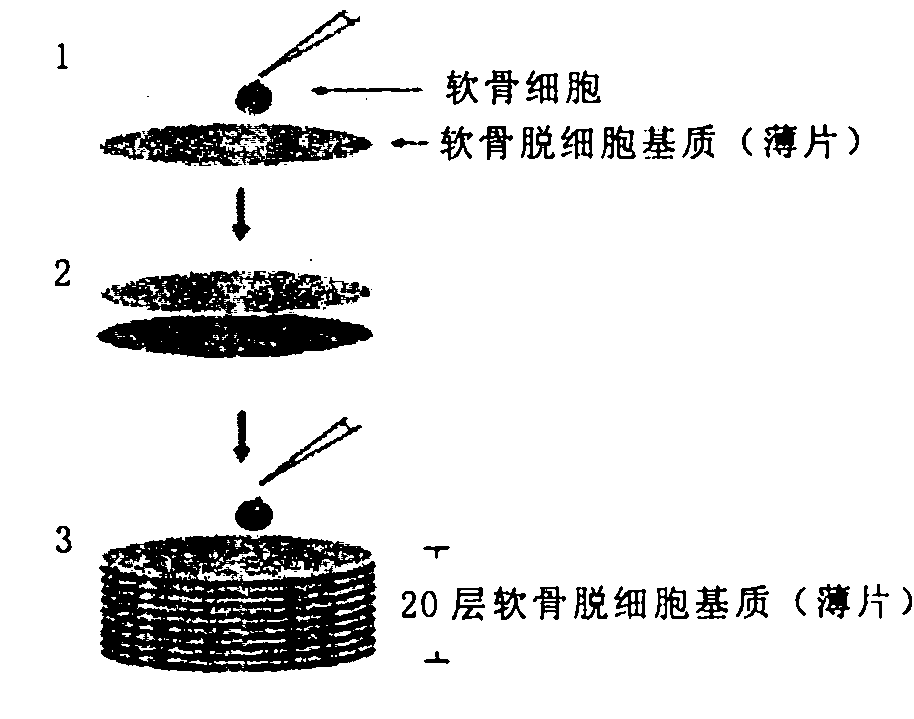

[0055] The preparation method of tissue engineered cartilage of the present invention comprises the steps:

[0056] In the first step, seed cells are seeded on one surface of the cartilage decellularized matrix of the present invention;

[0057] In the second step, another piece of cartilage decellularized matrix of the present invention is covered on the surface of the matrix inoculated with seed cells;

[0058] In the third step, the seed cells are seeded on another substrate covered in the second step without touching one surface of the seeded cells;

[0059] In the fourth step, the second to third steps are repeated until the superimposed cartilage decellularized matrix has 10-30 layers (preferably 15-25 layers), and the tissue-engineered cartilage graft of the present invention is obtained.

[0060] In short, the preparation method of tissue-engineered cartilage of the present invention is prepared according to the mode of "cartilage acellular matrix (sheet)-seed cells-c...

Embodiment 1

[0074] Preparation of cartilage decellularized matrix

[0075] Take fresh adult porcine auricle cartilage, cut it into a cylindrical shape with a diameter of 7 mm with a corneal trephine, cut it into circular slices with a thickness of 10-30 μm with a cryostat, put it in 1% SDS (Shanghai Shenggong) solution, and shake it on a shaker overnight. The sections were rinsed several times with distilled water, routinely stained with hematoxylin-eosin (HE) and fluorescent stained with diamidinophenylindole (DAPI) (Invitrogen, USA) to detect the degree of decellularization. Sections were freeze-dried using a freeze dryer (Virtis, USA).

[0076] result

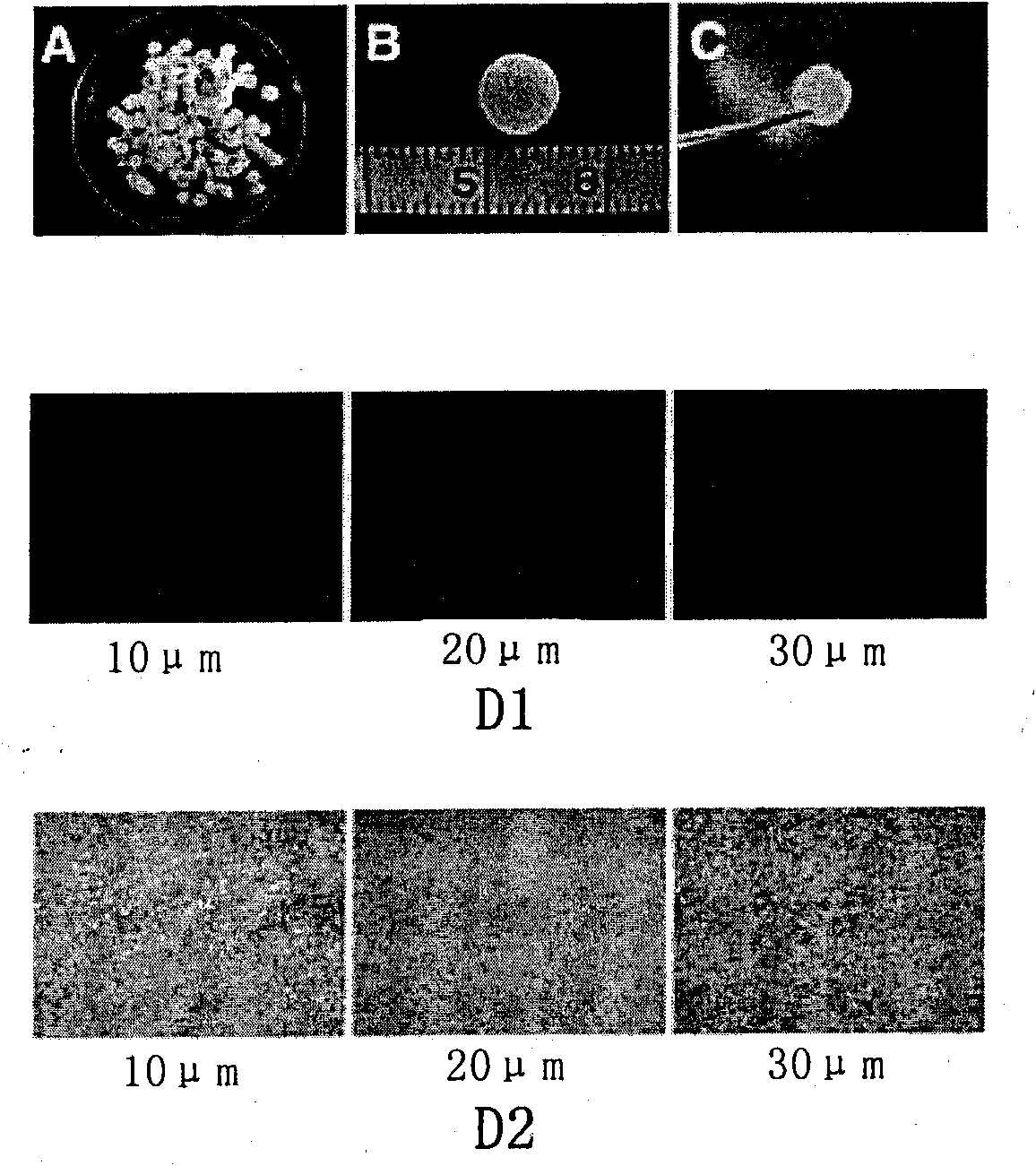

[0077] Porcine auricular cartilage was cut into a cylindrical shape with a diameter of 7 mm using a corneal trephine ( figure 1 A, B), cryostat cut into circular slices with a thickness of 10-30 μm ( figure 1 C), after 24 hours of SDS treatment, DAPI staining found no DAPI positive staining in the 10 μm thick section, indicating tha...

Embodiment 2

[0080] Preparation of tissue engineered cartilage grafts

[0081] Auricular chondrocyte culture

[0082] The auricular cartilage tissue of newborn pigs was taken, cut into 1×1×1 mm size, digested overnight with 0.1% collagenase, filtered through a filter with a pore size of 75 μm, and then added with high-sugar DMEM (Hyclone, USA) containing 10% fetal bovine serum ( FBS; Hyclone) culture medium, placed in 5% CO 2 Cultured in a 37°C incubator, cultivated to 90% confluence and then passaged.

[0083] Construction of cartilage in vitro by sandwich method

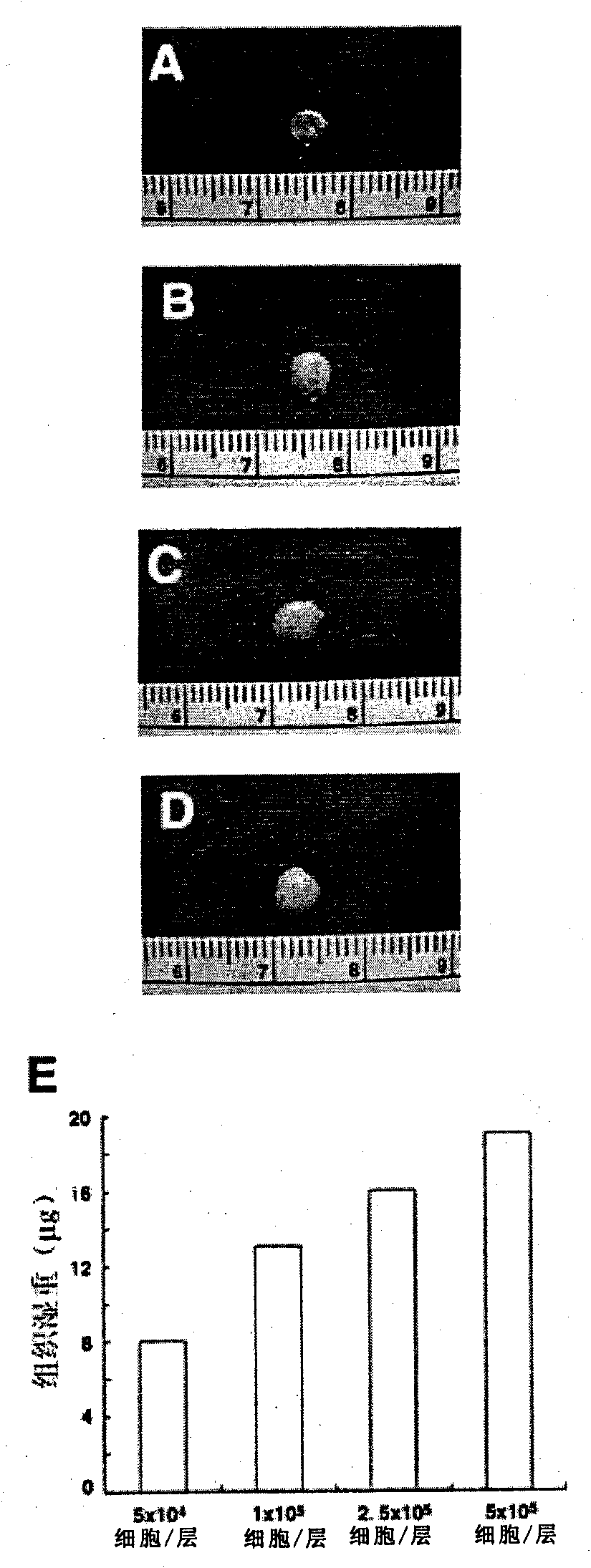

[0084] The cultured chondrocytes were collected by digestion with 0.25% trypsin, and resuspended to different concentration groups (10, 20, 50, 100×10 6 / ml), the cartilage decellularized matrix membrane and chondrocytes were stacked layer by layer in the culture dish in the manner of "membrane-cell suspension-membrane-cell suspension" ( figure 2 ), 5 μl of cell suspension per layer, and a total of 20 layers of membranes w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com