Method for producing 600g zinc-coated spangle-free hot-dip galvanized sheet based on thin slab continuous casting and rolling hot-based raw materials and acid plating continuous production line

A thin slab continuous casting, continuous casting and rolling technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve problems such as backward technology, achieve good surface quality, stable performance, high drawing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

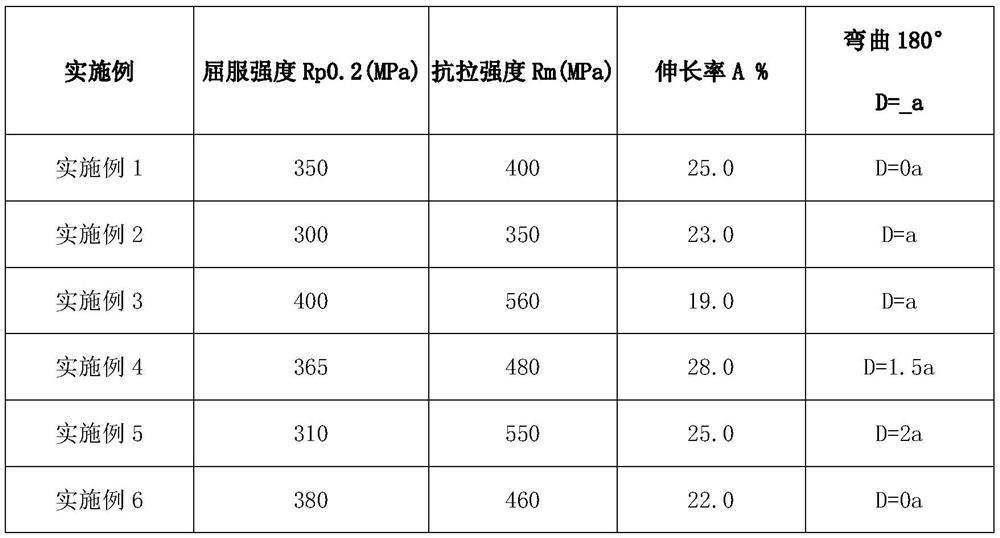

Examples

Embodiment 1

[0030] A process method for producing 600g zinc-coated zinc-free hot-dip galvanized sheet with hot-based raw materials for continuous casting and rolling of thin plates and continuous production line for pickling and galvanizing, comprising the following process steps: raw material rolls are continuously cast and rolled by full endless thin slabs Process production, and then pickling, leveling, heating, galvanizing, skin passivation, passivation, and coiling into hot-dip galvanized coils through the continuous pickling production line. The product specification is 2.0mm*1500mm, and the steel type is DX51D+Z.

[0031] As a preference, the full-endless thin slab continuous casting and rolling process refers to: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, rolls to an 8mm intermediate slab, and is heated to 1100°C by an induction heating furnace before entering 5 stands of finish rolling, coiling after lam...

Embodiment 2

[0040] A process method for producing 600g zinc-coated zinc-free hot-dip galvanized sheet with hot-based raw materials for continuous casting and rolling of thin plates and continuous production line for pickling and galvanizing, comprising the following process steps: raw material rolls are continuously cast and rolled by full endless thin slabs Process production, and then pickling, leveling, heating, galvanizing, skin passivation, passivation, and coiling into hot-dip galvanized coils through the pickling continuous production line. The product specification is 2.0mm*1500mm, and the steel type is SGHC.

[0041] As a preference, the full-endless thin slab continuous casting and rolling process refers to: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, rolls to a 20mm intermediate slab, and is heated to 1200°C by an induction heating furnace before entering 5 stands of finish rolling, coiling after lamina...

Embodiment 3

[0050] A process method for producing 600g zinc-coated zinc-free hot-dip galvanized sheet with hot-based raw materials for continuous casting and rolling of thin plates and continuous production line for pickling and galvanizing, comprising the following process steps: raw material rolls are continuously cast and rolled by full endless thin slabs Process production, and then pickling, leveling, heating, galvanizing, skin passivation, passivation, and coiling into hot-dip galvanized coils through the continuous pickling production line. The product specification is 3.0mm*1500mm, and the steel type is S350GD+Z.

[0051] As a preference, the full-endless thin slab continuous casting and rolling process refers to: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, rolls to a 15mm intermediate slab, and is heated to 1150°C by an induction heating furnace before entering 5 stands of finish rolling, coiling after la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com