Yeast cell wall and preparation method thereof, forage additive and preparation method thereof, and forage

A yeast cell wall and feed additive technology, applied in the field of yeast cell wall and preparation, to achieve the effect of improving litter rate, feasible process, and effective and feasible product application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

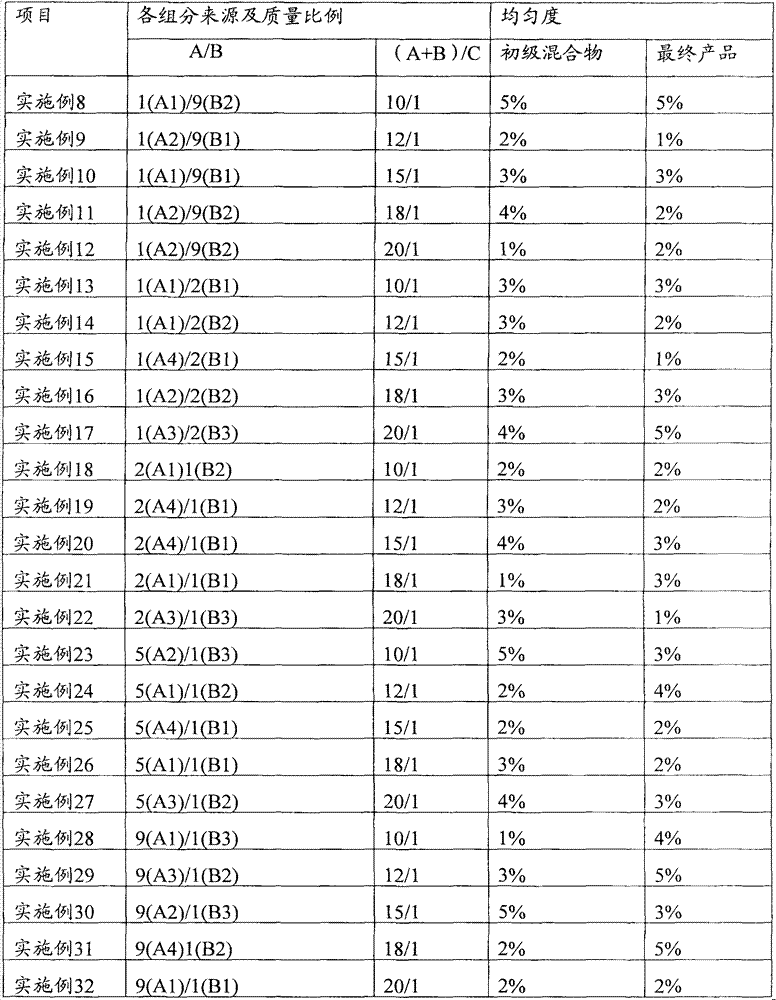

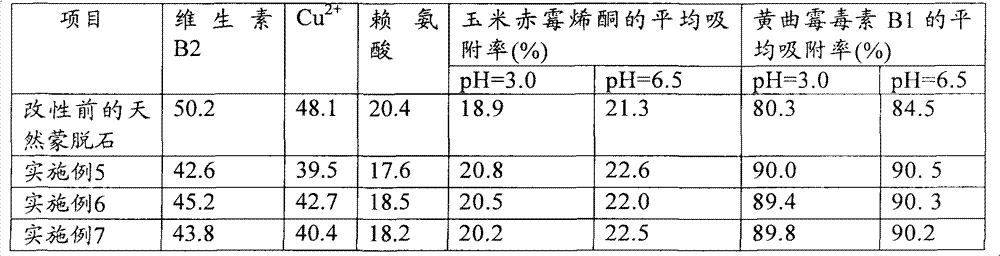

[0065] The preparation method of sodium-modified montmorillonite of the present invention is as follows: sodium polyphosphate and sodium carbonate are added in montmorillonite slurry, and described montmorillonite slurry is by dissolving natural montmorillonite in water, preferably every The volume of water added to one kilogram of natural montmorillonite is 1-1.5 liters, and the prepared montmorillonite slurry is stirred evenly, ground, aged to obtain a sodium montmorillonite slurry, and then mixed with an aluminum crosslinking agent, stirred, and hydrolyzed , that is. The mixing ratio of the sodium-modified montmorillonite slurry and the aluminum cross-linking agent described therein is 5-10mmol / g (with AlCl 3 molar number and natural montmorillonite mass), the preferred mixing ratio is 6mmol / g; wherein the addition of sodium polyphosphate is 5-10% of the natural montmorillonite addition, preferably 8%, the addition of sodium carbonate The amount is 0.5-1.0% of the added am...

Embodiment 1

[0081] The preparation of embodiment 1 yeast cell wall

[0082] First, the yeast is formulated into 20kg of yeast milk according to the ratio of dry matter to 10% by mass (mass ratio of yeast dry matter to water: 1:9), then boiled at 89°C for 1 hour, then cooled to 65°C, and added according to the dry matter of yeast Add papain at a ratio of 2‰, adjust the pH to 5.5, and act for 6 hours; then adjust the pH to 5.0, the temperature is 68°C, add nuclease at a ratio of 1.0‰ of yeast dry matter, and act for 8 hours, then Lower the temperature to 50°C, adjust the pH to 5.6, add bacterial protease according to the proportion of 0.2‰ of yeast dry matter, and act for 5 hours; then inactivate the enzyme at 85°C for 30 minutes, and finally centrifuge, take the heavy phase after centrifugation, and carry out The yeast cell wall A1 was obtained by powder spraying and drying, the mass content of β-yeast glucan was determined to be 20%, and the mass content of mannan oligosaccharide was 60%....

Embodiment 2

[0083] The preparation of embodiment 2 yeast cell wall

[0084] Firstly, the yeast is formulated into 20kg of yeast milk according to the ratio of dry matter to 10%, and then boiled at 93°C for 0.5 hours, then cooled to 63°C, and papain is added according to the ratio of yeast dry matter to 1‰, and the pH is adjusted to 5.7. Act for 5 hours; then adjust the pH to 5.3, the temperature is 68°C, add nuclease according to the ratio of 0.5‰ of yeast dry matter, after 9 hours of action, then lower the temperature to 48°C, adjust the pH to 5.4, and add according to the amount of yeast dry matter Add bacterial protease at a ratio of 0.3‰, and act for 4 hours; then inactivate the enzyme at 80°C for 50 minutes, and finally centrifuge, take the heavy phase after centrifugation, and dry it by powder spraying to obtain yeast cell wall A2. The mass content of polysaccharide is 25%, and the mass content of manno-oligosaccharide is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com