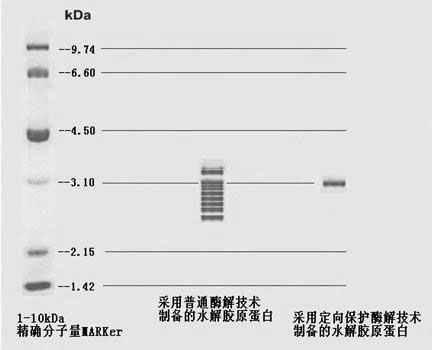

Method for extracting hydrolyzed collagen from bovine cartilage

A technology for hydrolyzing collagen and cartilage, which is applied in the field of bioengineering, can solve problems such as poor molecular weight uniformity in the step-by-step range, lower biological activity, and affect product taste, so as to achieve the effects of ensuring excellent quality, increasing product content, and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Cut off fat and other sundries from the bovine cartilage taken out of the halal slaughterhouse, weigh 100kg, cut into small pieces, soak in 3% sodium hydroxide for 24 hours, and wash. Add 200kg of water, heat to 45°C, add papain at a ratio of 8500-9000U / g substrate, then add 0.03% M0111-9 compound enzymolysis protection agent, keep at 45-50°C, stir for 5 hours ; Then use sodium hydroxide to adjust the pH to 9.0-9.5, add 2709 alkaline protease according to the ratio of 5000U / g substrate, stir the enzymolysis at a constant temperature of 40-45°C for 3 hours, and inactivate the enzyme at 80-85°C For 10 minutes, cool to 30-40°C, add 3600ml (1.2% of the amount of feed liquid) of hydrogen peroxide, keep warm at 30-40°C for 2.5 hours; add 6kg of activated carbon to the feed liquid, stir for 2.5 hours, and use clarification The filter plate was filtered, and the obtained filtrate was subjected to ultrafiltration through a 200 Da nanofiltration membrane, and the retentate was sp...

Embodiment 2

[0039] Cut off fat and other sundries from the bovine cartilage taken out of the Muslim slaughterhouse, weigh 500kg, cut into small pieces, soak in 3% sodium hydroxide for 24 hours, and wash. Add 1000kg of water, heat to 45°C, add papain at a ratio of 8500-9000U / g substrate, then add 0.03% M0111-9 compound enzymolysis protection agent, keep at 45-50°C, stir for 5 hours ; Then use sodium hydroxide to adjust the pH to 9.0-9.5, add 2709 alkaline protease according to the ratio of 5000U / g substrate, stir the enzymolysis at a constant temperature of 40-45°C for 3 hours, and inactivate the enzyme at 80-85°C 10 minutes, cool to 30-40°C, add 18000ml (1.2% of the amount of feed liquid) of hydrogen peroxide, keep warm at 30-40°C for 2.5 hours; then add 30kg of activated carbon to the feed liquid, stir for 2.5 hours, Filtrate through a filter plate, and the obtained filtrate is subjected to ultrafiltration through a 200 Da nanofiltration membrane, and the retentate is spray-dried under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com