Method for extracting fucoidan and removing heavy metals from kelps

A technology of fucoidan and heavy metals, which is applied in the field of marine biology, can solve the problems of little research and harm to human body, and achieve the effect of simple steps, less impurity content and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

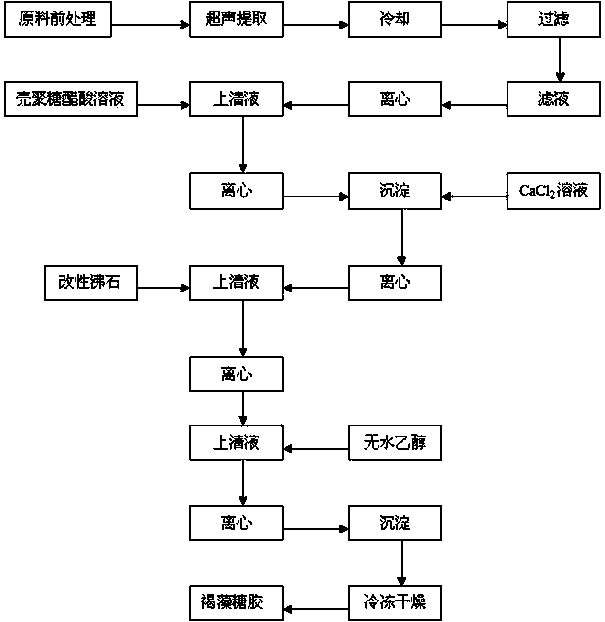

Method used

Image

Examples

Embodiment 1

[0027] Take about 1.5kg of dried kelp, remove impurities, wash, dry in the air at a constant temperature of 60°C, and crush to 50 meshes to obtain kelp powder. Take 1kg of kelp powder, add 10L of 10g / L CaCl 2 The solution is extracted with ultrasonic waves, and the extraction conditions are as follows: the ultrasonic power is 500W, the temperature is 35°C, and the extraction time is 40min. After the extraction was completed, the extract was cooled to room temperature, filtered through a 60-mesh nylon mesh, the filtrate was collected, and then the filtrate was centrifuged to obtain the supernatant. Add 5 times the volume of chitosan acetic acid solution to the supernatant, stir for 30 min, centrifuge, and collect the precipitate. The preparation method of the chitosan solution is as follows: add 1 g of chitosan powder with a molecular weight of 300,000 and a deacetylation degree of 90% to 1% acetic acid, heat to 40° C., and stir until completely dissolved.

[0028] Add 3 time...

Embodiment 2

[0031] Take about 1.5kg of dried kelp, remove impurities, wash, dry in the air at a constant temperature of 60°C, and crush to 50 meshes to obtain kelp powder. Take 1kg of kelp powder, add 10L of 10g / L CaCl 2 The solution is extracted with ultrasonic waves, and the extraction conditions are as follows: the ultrasonic power is 500W, the temperature is 30°C, and the extraction time is 30 minutes. After the extraction was completed, the extract was cooled to room temperature, filtered through a 60-mesh nylon mesh, the filtrate was collected, and then the filtrate was centrifuged to obtain the supernatant. Add 5 times the volume of chitosan acetic acid solution to the supernatant, stir for 30 min, centrifuge, and collect the precipitate. Described chitosan solution is with embodiment 1.

[0032] Add 4 times the volume of 3mol / L CaCl to the above-mentioned precipitate 2 Add the solution while stirring, let stand for 30min, centrifuge, and take the supernatant. Add the same volu...

Embodiment 3

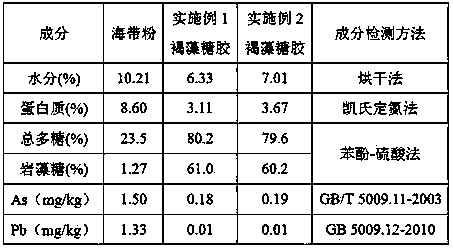

[0035] Sea-tangle powder, the relevant components of the products obtained in Examples 1 and 2, and the content of heavy metals are detected, and the results are shown in Table 1.

[0036] Table 1 Comparison of components and heavy metal contents between kelp powder and fucoidan

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com