Production method of halal chicken-flavor seasoning powder

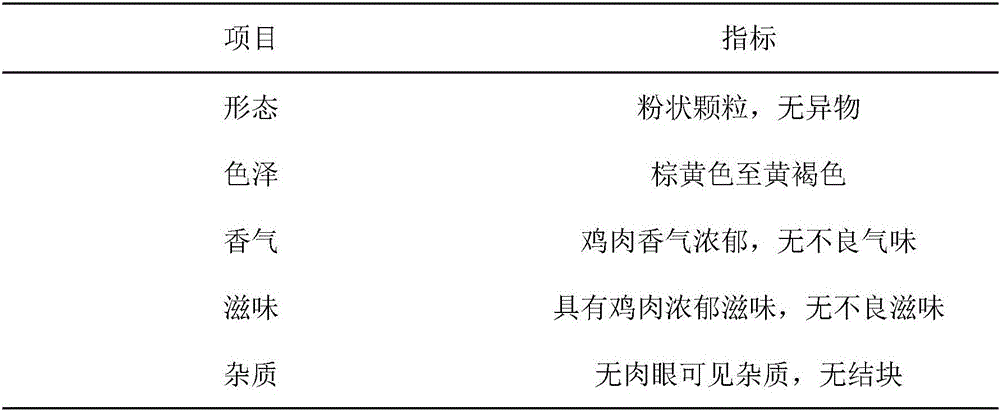

A production method and technology of seasoning powder, which is applied in the production field of chicken flavor seasoning powder, can solve problems such as insufficient antibacterial performance and discounted nutritional and health effects, and achieve the effect of rich flavor level, sufficient release, and improved protein hydrolysis degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

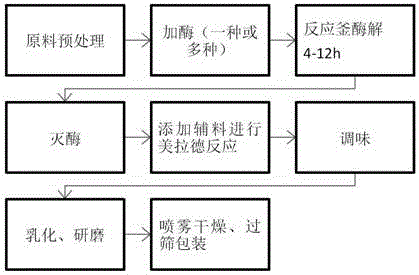

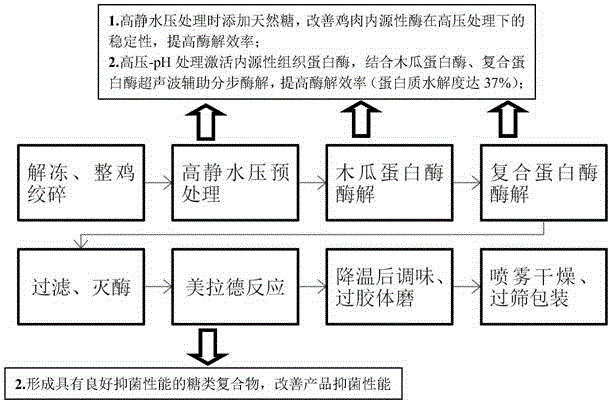

Method used

Image

Examples

Embodiment 1

[0034] After the whole chicken is thawed, it is crushed by a meat grinder, and 3 mg of fucoidan and 6 mg of mannose are added per gram of raw materials (fucoidan is purchased from Xi’an Tongze Biotechnology Co., Ltd., and mannose is purchased from Zhejiang Lvzhou Biotechnology Co., Ltd.). Then use whole chicken raw materials: water = 1:5 (w / v), add water and mix evenly, and perform high hydrostatic pressure treatment. The high hydrostatic pressure treatment method is: 200MPa treatment at 5°C for 10 minutes, and then add citric acid to adjust the pH to about 7.0 to obtain chicken meat. Homogenate (solid content is about 16%);

[0035] First heat the chicken homogenate to 55°C, under the action of 0.1wt% papain (purchased from Zhengzhou Linuo Biotechnology Co., Ltd., enzyme activity: 500,000 u / g), ultrasonically assisted (ultrasonic parameters: 200W, 40KHz; WBD -10012P ultrasonic generator, Shenzhen Kemeida Ultrasonic Equipment Co., Ltd.) enzymatic hydrolysis for 1.5h. In the s...

Embodiment 2

[0045] After the whole chicken is thawed, it is crushed by a meat grinder, and 5 mg of fucoidan and 10 mg of mannose are added per gram of raw materials (fucoidan is purchased from Xi’an Tongze Biotechnology Co., Ltd., and mannose is purchased from Zhejiang Lvzhou Biotechnology Co., Ltd.). Then use the whole chicken raw material: water = 1:6 (w / v) and add water to mix evenly, and perform high hydrostatic pressure treatment. The high hydrostatic pressure treatment method is: treat at 200MPa at 6°C for 10 minutes, and then add citric acid to adjust the pH to about 7.0 to obtain chicken meat. Homogenate (solid content is about 14%);

[0046] First heat the chicken homogenate to 55°C, under the action of 0.1wt% papain (purchased from Zhengzhou Linuo Biotechnology Co., Ltd., enzyme activity: 500,000 u / g), ultrasonically assisted (ultrasonic parameters: 200W, 40KHz; WBD -10012P ultrasonic generator, Shenzhen Kemeida Ultrasonic Equipment Co., Ltd.) enzymatic hydrolysis for 1h. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com