Method for judging and positioning bridge cable corrosion

A bridge cable and cable technology, applied in the field of non-destructive testing, can solve problems such as harsh conditions of use, poor ability to work at heights, hidden dangers of bridge safety, etc., to achieve the effects of reducing calculation errors, saving testing costs, and avoiding linear distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0031] This example includes the following specific steps:

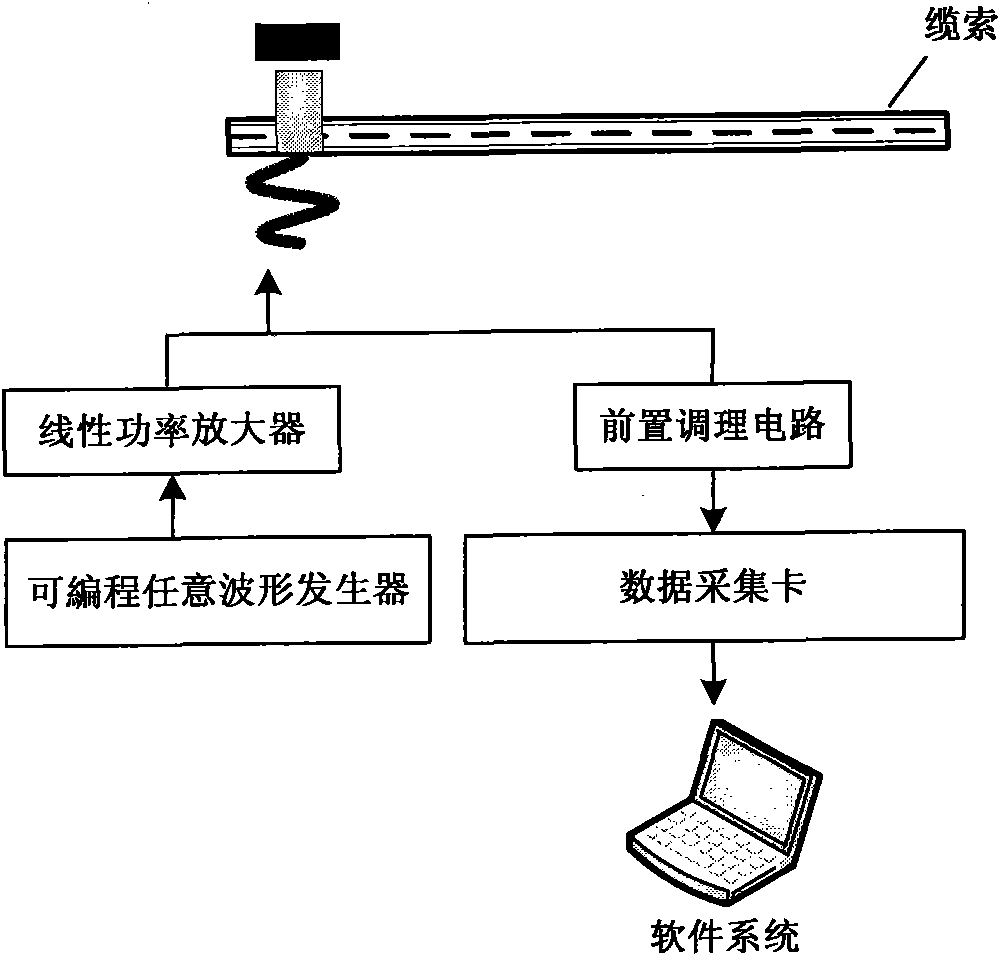

[0032] 1. If figure 1 As shown, a magnetostrictive sensor is installed on the cable to be tested. The sensor includes an excitation receiving coil and a permanent magnet bias magnetic field. The sensor is installed at one end of the cable to be tested;

[0033] 2. The programmable arbitrary waveform generator generates trigger group pulses, which are input to the sensor through the linear power amplifier, and the response signal is received on the same sensor. The card is read into the software system of the laptop;

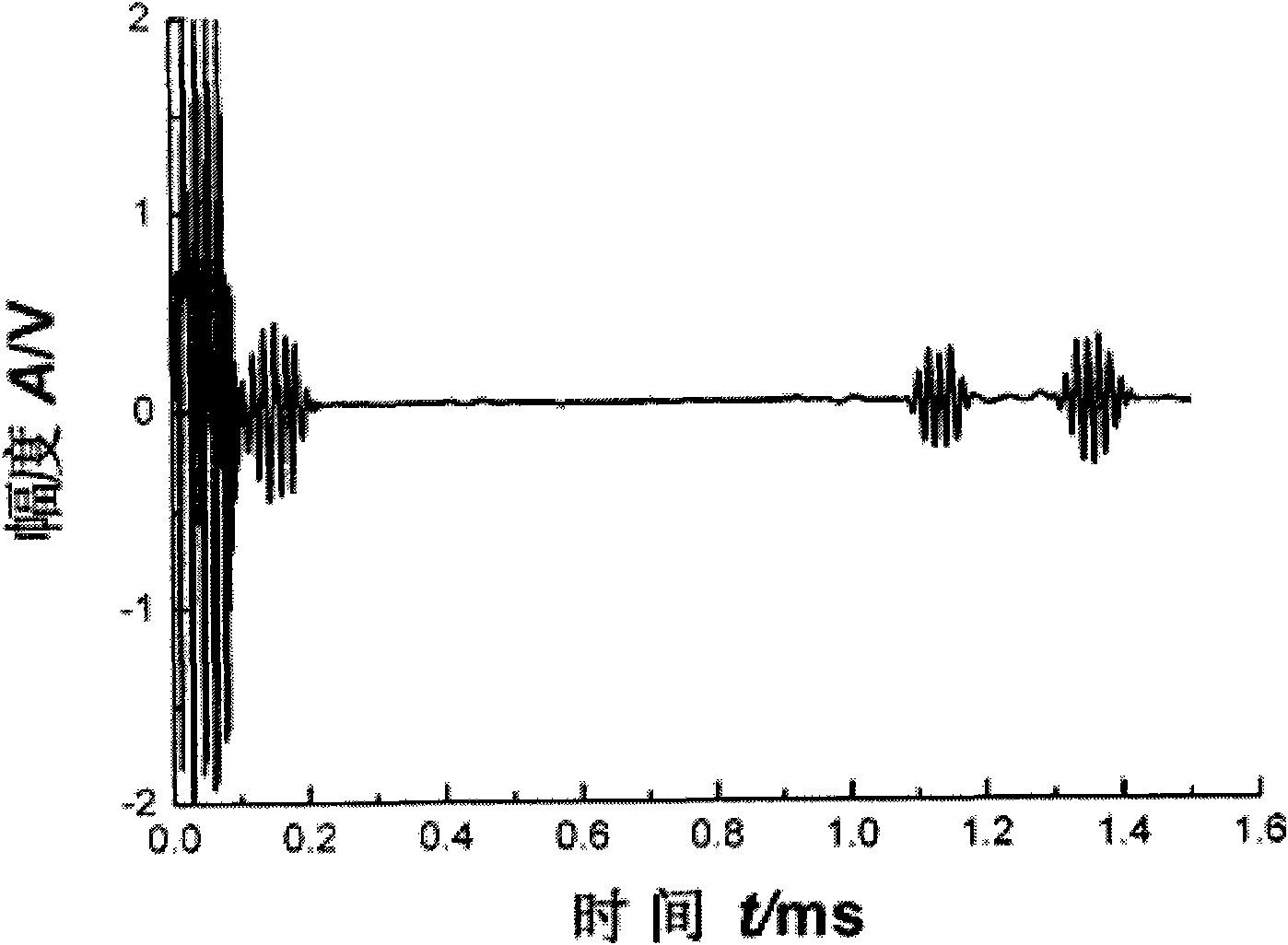

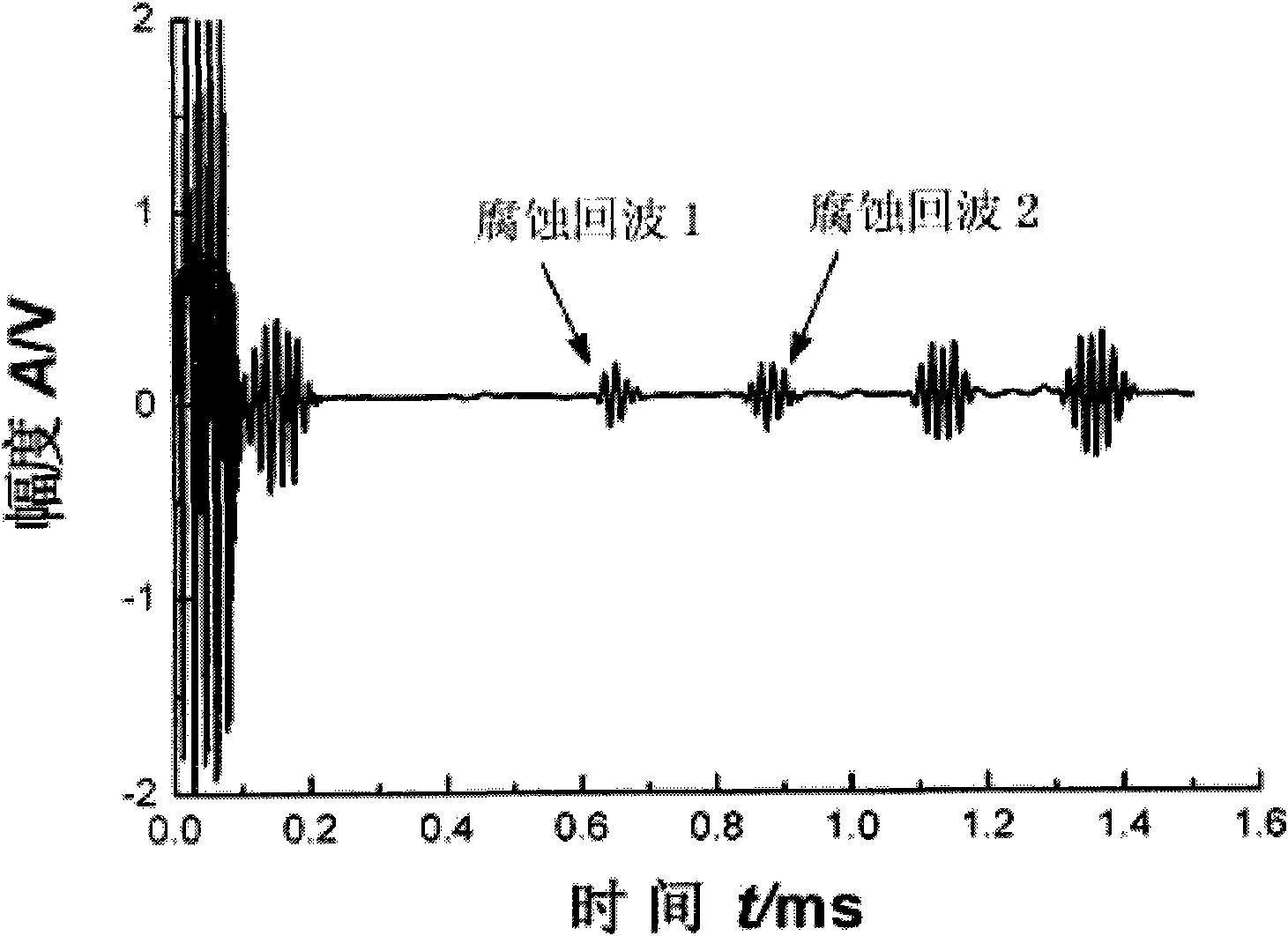

[0034] 3. According to the geometric size, material characteristics and excitation signal conditions of the cable, a fine numerical model for cable corrosion judgment is established by using finite element technology, and a standard comparison signal is provided for the actual measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com