Method for preparing graphene solution based on supercritical carbon dioxide induction solution phase transformation technology

A graphene solution and carbon dioxide technology, applied in the production of bulk chemicals and other directions, can solve problems such as graphene, and achieve the effects of simple and easy method, good development prospects, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 200 mg of PVP in 10ml of deionized water, and then take 50 mg of graphite powder and dissolve them in the above solution respectively. Ultrasonicate the prepared solution in a cold water bath (10°C) for 3 hours under 240W power to make the graphite evenly mixed in the solution. ;Quickly transfer the solution after ultrasonication for 3 hours to a 50ml high-pressure reactor, and fill the reactor with carbon dioxide at a flow rate of 150 ml / h to keep the solution at 40°C and 16MPa for 3 hours , at the same time, stir the solution to make the solution fully contact with supercritical carbon dioxide. After the reaction, slowly empty the carbon dioxide in the reactor within 1 hour; take out the solution in the reactor, and ultrasonically 2h; then centrifuge the solution at 3000 rpm for 45 min, and take out the supernatant, which is the graphene solution.

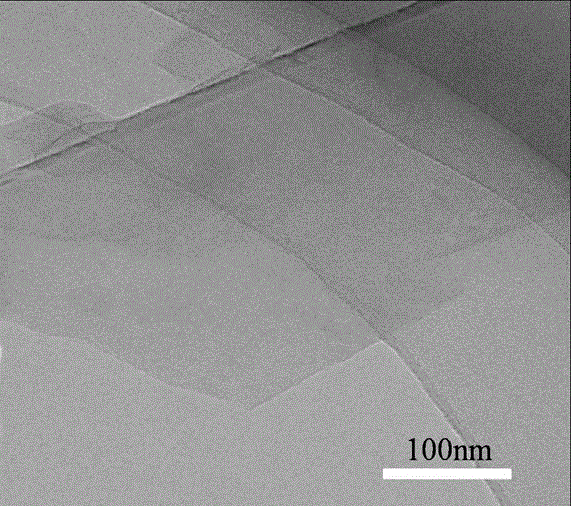

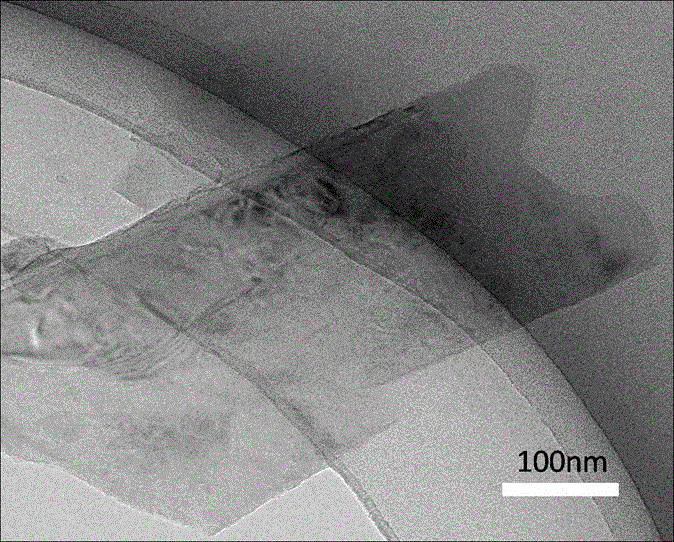

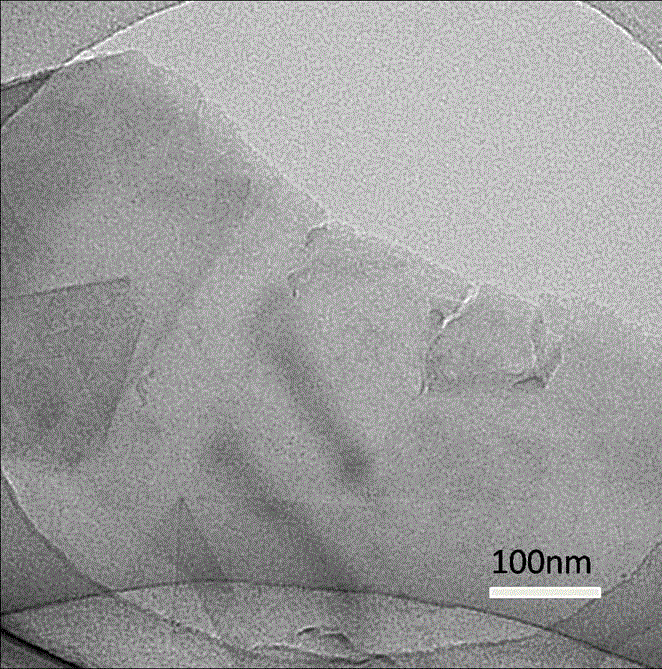

[0020] Take a drop of graphene solution and drop it on the microgrid, dry it at room temperature and use transm...

Embodiment 2-11

[0023] The solvent deionized water is changed into ethanol, and the volume concentration of ethanol is 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, 95%, and others are all the same as in Example 1 .

[0024]

Embodiment 12-18

[0026] The pressure of feeding carbon dioxide is adjusted to 6MPa, 8MPa, 10MPa, 12MPa, 14MPa, 18MPa, 20MPa respectively in turn, and the others are the same as in Example 1.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com