Online testing device for safety valve and online testing method thereof

A detection device and safety valve technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as poor safety and complicated operation, and achieve improved applicability, good safety, and intelligent devices effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

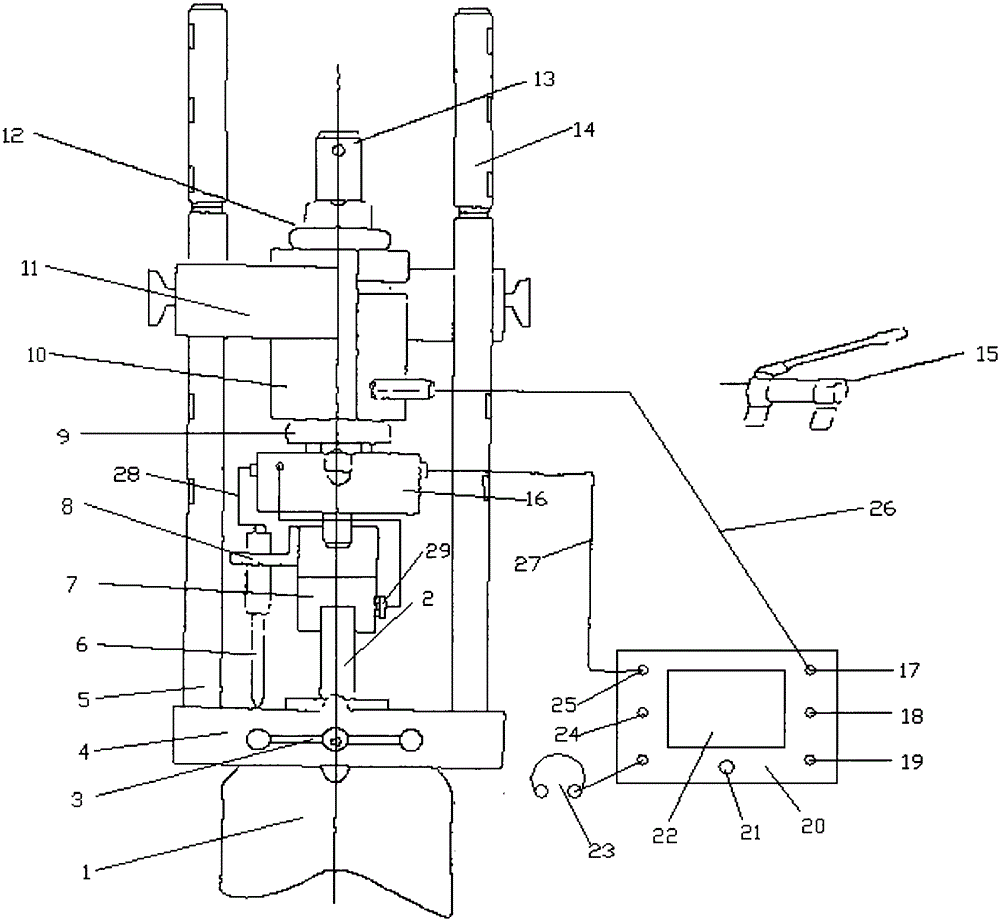

Image

Examples

Embodiment 2

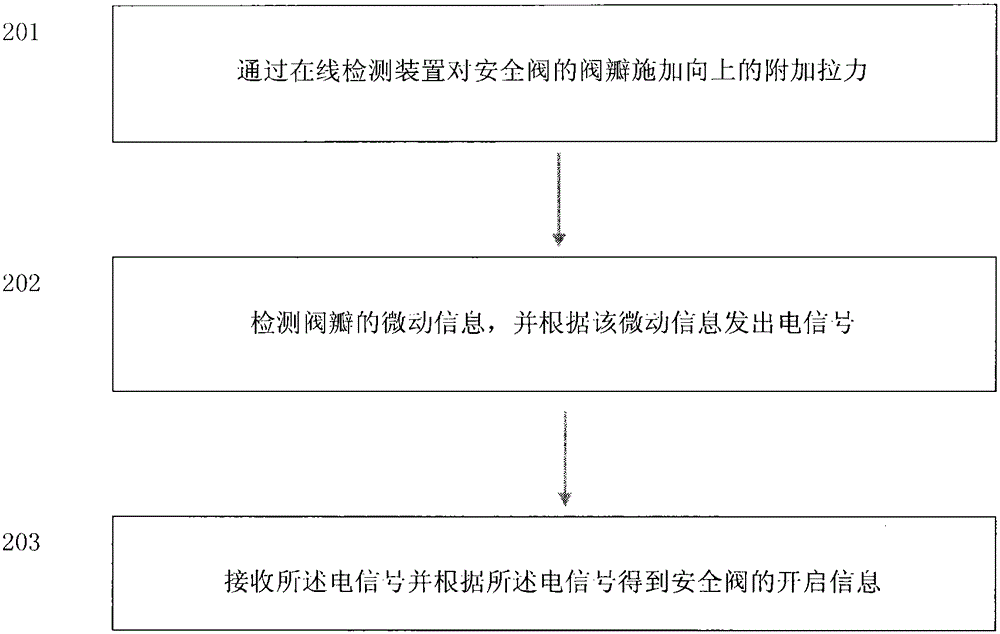

[0055] Such as figure 2 A method for opening a safety valve is shown, comprising the steps of:

[0056] 201. Apply an upward additional pulling force to the disc of the safety valve through an online detection device;

[0057] 202. Detect the micro-movement information in the critical opening state of the valve disc, and send an electrical signal according to the micro-motion information;

[0058] 203. Receive the electrical signal and obtain opening information of the safety valve according to the electrical signal;

[0059] The opening method of the embodiment of the present invention is to detect the micro-movement information in the critical opening state of the valve clack, and generate an electrical signal to obtain the opening information of the safety valve. This method judges whether the safety valve is open or not. It does not need to pull up the valve disc to find the characteristic points on the curve of the applied force changing with time. It only needs to det...

Embodiment 3

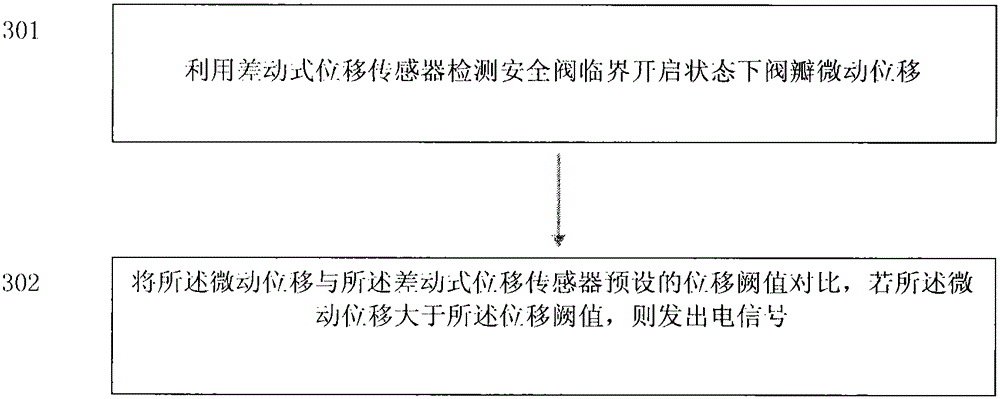

[0115] Such as Figure 10 As shown, this embodiment provides a method for judging the opening of a safety valve, including the following steps:

[0116] 1001, implementing an upward lifting force on the safety valve through a hydraulic method and an online detection device;

[0117] 1002. Use the differential displacement sensor to judge the opening state of the safety valve in the critical opening state, and calculate the actual opening pressure of the safety valve according to the lift force value at this time.

[0118] The opening method of the embodiment of the present invention detects the displacement of the safety valve, and judges whether the safety valve is opened according to the range of the displacement.

[0119] The specific working principle is as follows:

[0120] Consider a spring-loaded safety valve that is closed and functioning properly. Such as Figure 7 As shown, part of the spring preload Fd acting downward on the valve disc is used to resist the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com