Preparation method of asymmetric porous membrane based on electrostatic spinning technology

An electrospinning technology, an electrospinning technology, applied in the field of membrane materials, can solve the problems of long crosslinking time and difficult control of membrane pore size, and achieve the effect of wide application range, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

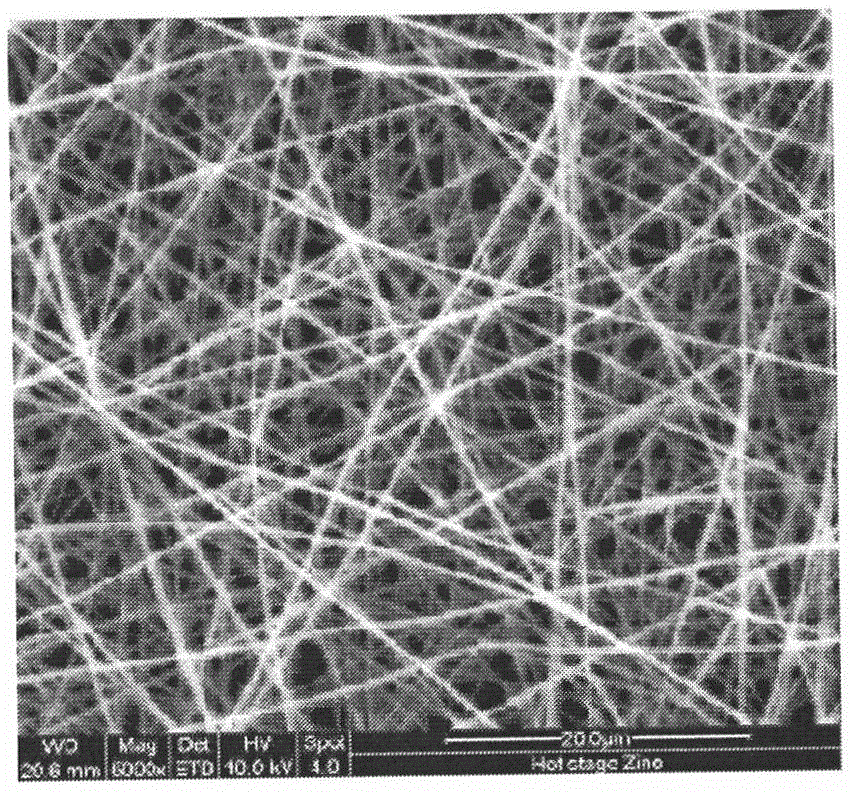

[0034] (1) Weigh a certain mass of cellulose acetate (CA, molecular weight 30000) and dissolve it in a mixed solvent of acetone / N, N-dimethylacetamide (DMAc) (2 / 1 (v / v)), magnetically stir After 12 hours, a CA spinning solution with a mass fraction of 21% was obtained, and the prepared CA spinning solution was added to a spinning syringe, received by a commonly used polyester (PET) non-woven fabric, and subjected to high-voltage electrospinning to obtain a double-layer fiber Membrane, electrospinning parameters are: voltage 16kV, temperature 20°C, relative humidity 45%, spinning solution propulsion speed 0.001mm / s, spinning needle inner diameter 0.5mm, receiving distance 20cm;

[0035] (2) Mix acetone / deionized water / dioctyl phthalate (DOP) with a volume ratio of 1 / 3 / 1 evenly to prepare a cross-linking liquid, and add it to a special container (self-made);

[0036] (3) Cover the container filled with the cross-linking solution with a double-layer fiber membrane spun, the elect...

Embodiment 2

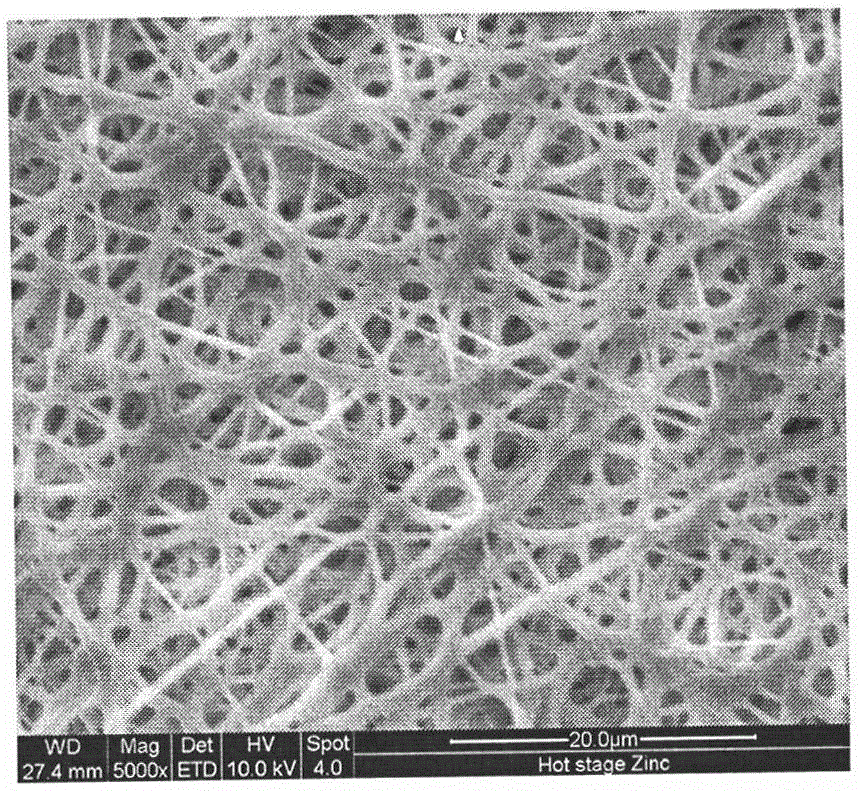

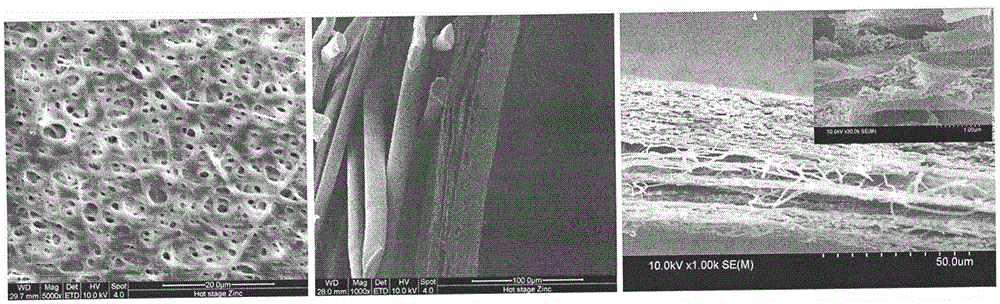

[0039] Adjust the volume ratio of acetone / deionized water / dioctyl phthalate in Step 2) of Example 1 to 2 / 3 / 1, and the rest are the same as in Example 1 to obtain a CA porous membrane. The surface morphology of the CA porous membrane is as follows image 3 As shown, the third picture is a cross-sectional view of the non-woven fabric with the functional layer removed. From the figure, it can be clearly seen that the functional layer is connected and has a gradient-distributed pore structure. The average pore size of the CA porous membrane is 0.61um, and the pure water flux is 2111L.m -2 .h -1 , The rejection rate is 99.75%.

Embodiment 3

[0041] Adjust the volume ratio of acetone / deionized water / dioctyl phthalate in Step 2) of Example 1 to 3 / 2 / 1, and the rest are the same as in Example 1 to obtain a CA porous membrane. The surface morphology of the porous membrane is as Figure 4 As shown, the average pore size is 0.32um, and the pure water flux is 329L.m -2 .h -1 , The rejection rate is 99.93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com