High waterproof moisture-permeable flame-retardant tent fabric processing method

A waterproof and moisture-permeable, tent fabric technology, applied in the field of flame-retardant processing, high waterproof and moisture-permeable fabrics, can solve the problems of poor rainstorm resistance, no flame retardancy, uncertainty, etc., to achieve high flexibility and high flexibility. The effect of resilience, increased bonding fastness, and good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

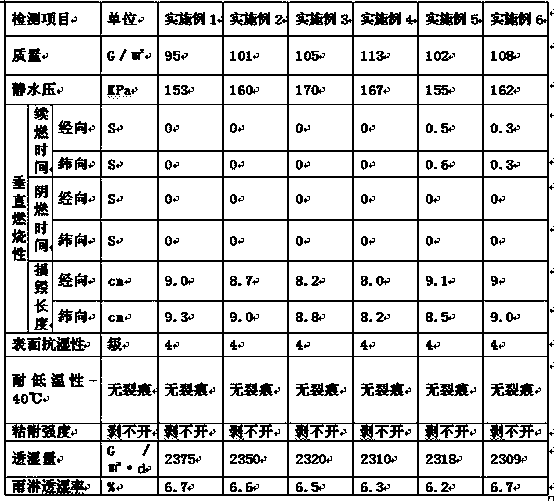

Examples

Embodiment 1

[0035] 1. Base fabric selection: use 65D polyester taffeta that has been water-repellent (water-repellent), base fabric 63g / ㎡, surface moisture resistance level 4;

[0036] 2. Preparation of bottom microporous polyurethane coating glue:

[0037] Raw material ratio by weight

[0038] Add 10 parts of toluene, 5 parts of methyl ethyl ketone, and 5 parts of dimethylformamide (DMF) into 100 parts of microporous oily polyether polyurethane resin and stir well; add 1 part of polyurethane modified silicone resin and stir well Add 2 parts of butyl ether-blocked melamine bridging agent (crosslinking agent) and stir evenly; then add 1 part of acid accelerator and stir evenly to prepare the bottom microporous polyurethane coating glue;

[0039] 3. Preparation of the middle layer hydrophilic polyurethane flame retardant coating primer:

[0040] Raw material ratio by weight

[0041] Add 0.1 part of solvent-based wetting and dispersing agent to 30 parts of toluene and stir evenly; add 3 p...

Embodiment 2

[0050] 1. Selection of base fabric: polyester taffeta with 65D water-repellent (water-repellent) finishing, base fabric 63g / ㎡, surface moisture resistance level 4;

[0051] 2. Preparation of bottom microporous polyurethane coating glue:

[0052] Raw material ratio by weight

[0053] Add 12 parts of toluene, 6 parts of butanone, and 8 parts of dimethylformamide (DMF) into 100 parts of microporous oily polyether polyurethane resin, and stir well; add 1.5 parts of polyurethane modified silicone resin, and stir well Add 2.2 parts of butyl ether-blocked melamine bridging agent (crosslinking agent) and stir evenly; then add 1.5 parts of acid accelerator and stir evenly to prepare the bottom microporous polyurethane coating glue;

[0054] 3. Preparation of the middle layer hydrophilic polyurethane flame retardant coating primer:

[0055] Raw material ratio by weight

[0056] Add 0.15 parts of solvent-based wetting and dispersing agent to 35 parts of toluene and stir evenly; add 4 ...

Embodiment 3

[0065] 1. Base fabric selection: use 65D polyester taffeta that has been water-repellent (water-repellent), base fabric 63g / ㎡, surface moisture resistance level 4;

[0066] 2. Preparation of bottom microporous polyurethane coating glue:

[0067] Raw material ratio by weight

[0068] Add 13 parts of toluene, 7 parts of butanone, and 7 parts of dimethylformamide (DMF) to 100 parts of microporous oily polyether polyurethane resin, and stir well; add 1.8 parts of polyurethane modified silicone resin, and stir well ; Add 2.5 parts of butyl ether-blocked melamine bridging agent (crosslinking agent), and stir evenly; then add 2 parts of acid accelerator and stir evenly, to prepare the bottom microporous polyurethane coating glue;

[0069] 3. Preparation of the middle layer hydrophilic polyurethane flame retardant coating primer:

[0070] Raw material ratio by weight

[0071] Add 0.2 parts of solvent-based wetting and dispersing agent to 40 parts of toluene and stir evenly; add 5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com