Super-hydrophilic self-cleaning oil-water separation membrane as well as preparation method and application thereof

An oil-water separation membrane and oil-water separation technology, applied in the field of polymer materials and environmental engineering, can solve the problems of low efficiency of oil/water emulsion, negative impact on the ecosystem, cumbersome operation, etc., achieve excellent self-cleaning and anti-fouling performance, fast and effective Effect of separation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

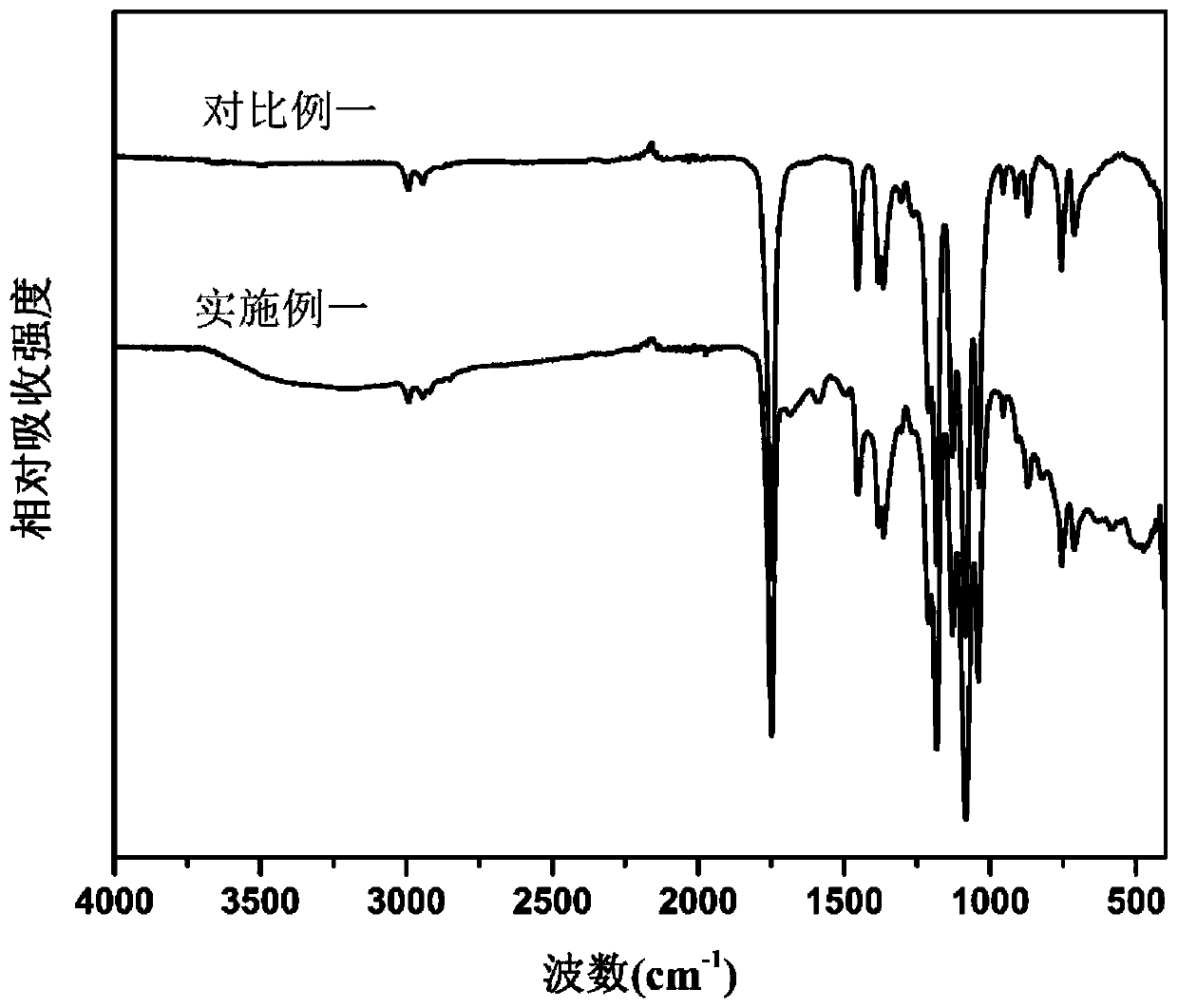

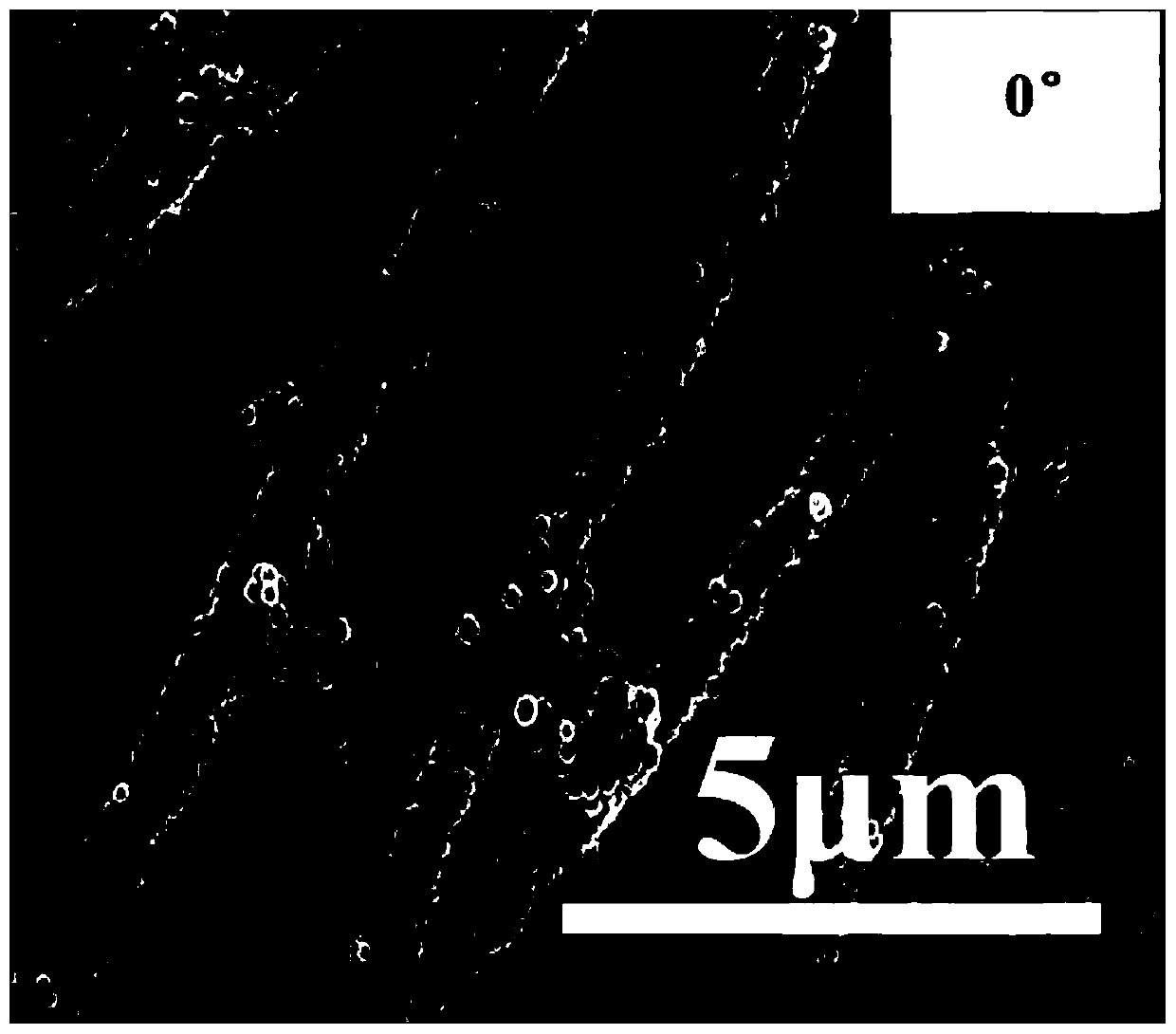

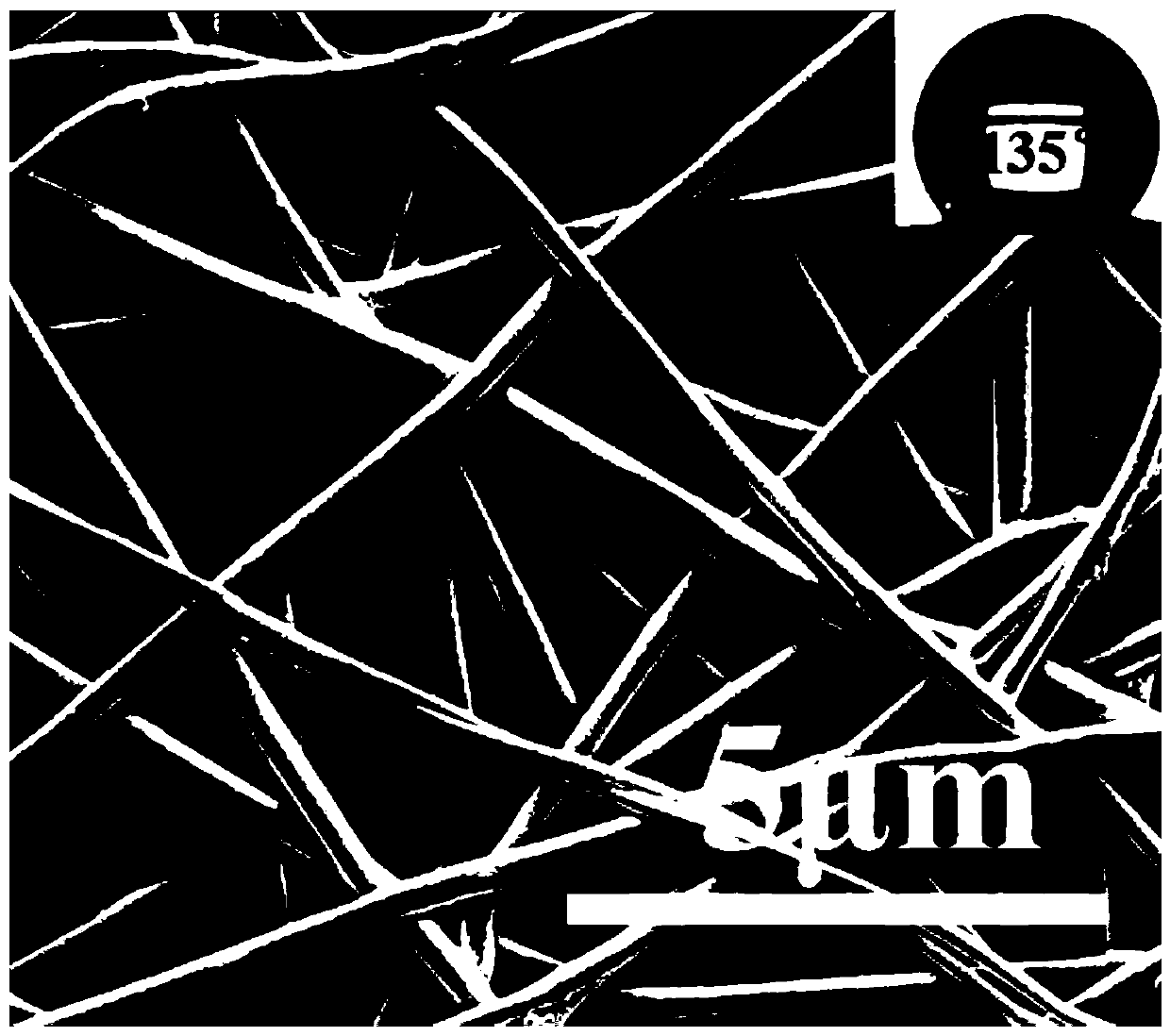

Embodiment 1

[0058] Dissolve the weighed equal mass of PLLA and PDLA in an equal volume of chloroform / hexafluoroisopropanol mixed solvent to obtain a mixed solution. The mixed solution is electrospun at a rate of 1mL / h at 10-20kV to form a membrane, and then the membrane is heated at 100 Anneal at ~170°C for 1 hour; mix 5 mg / mL GA Tris solution ((pH=8)) with 1 mg / mL TBT alcohol solution at a volume ratio of 4:1, and anneal the annealed film at 25°C Immerse it in the above solution for 12 hours; then rinse it with distilled water for 1 hour, and dry it at 60° C. to obtain a superhydrophilic stereocomplex polylactic acid film.

[0059] Table 1 shows the modified liquid raw materials and their proportions, reaction time, contact angle of the obtained film to water and hydrophilic and hydrophobic properties of each embodiment and comparative example.

Embodiment 2

[0067] Dissolve the weighed equal mass of PLLA and PDLA in an equal volume of chloroform / hexafluoroisopropanol mixed solvent, electrospin at a rate of 1mL / h at 10-20kV to form a membrane, and then anneal the membrane at 100-170°C 1h; After mixing 5mg / mL GA Tris solution and 5mg / mL TBT alcohol solution at a volume ratio of 4:1, immerse the annealed film in the above solution at 25°C for 12h; then wash it with distilled water After rinsing for 1 hour, dry at 60°C to obtain a superhydrophilic stereocomplex polylactic acid film.

Embodiment 3

[0069] Dissolve the weighed equal mass of PLLA and PDLA in an equal volume of chloroform / hexafluoroisopropanol mixed solvent, electrospin at a rate of 1mL / h at 10-20kV to form a membrane, and then anneal the membrane at 100-170°C 1h; After mixing 5mg / mL GA Tris solution and 1mg / mL TBT alcohol solution at a volume ratio of 4:1, immerse the annealed film in the above solution at 25°C for 24h; then wash it with distilled water After rinsing for 1 hour, dry at 60°C to obtain a superhydrophilic stereocomplex polylactic acid film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Separation flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com