Polyvinylidene difluoride hollow fiber micro-filtration membrane with permanent hydrophilicity, and preparation method thereof

A polyvinylidene fluoride and microfiltration membrane technology, which is applied in the preparation of the polyvinylidene fluoride hollow fiber microfiltration membrane and the field of polyvinylidene fluoride hollow fiber microfiltration membrane, can solve the problem of difficult adsorption on the membrane surface and membrane pores. Blockage, difficult to control the length of the graft segment, etc., to achieve good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

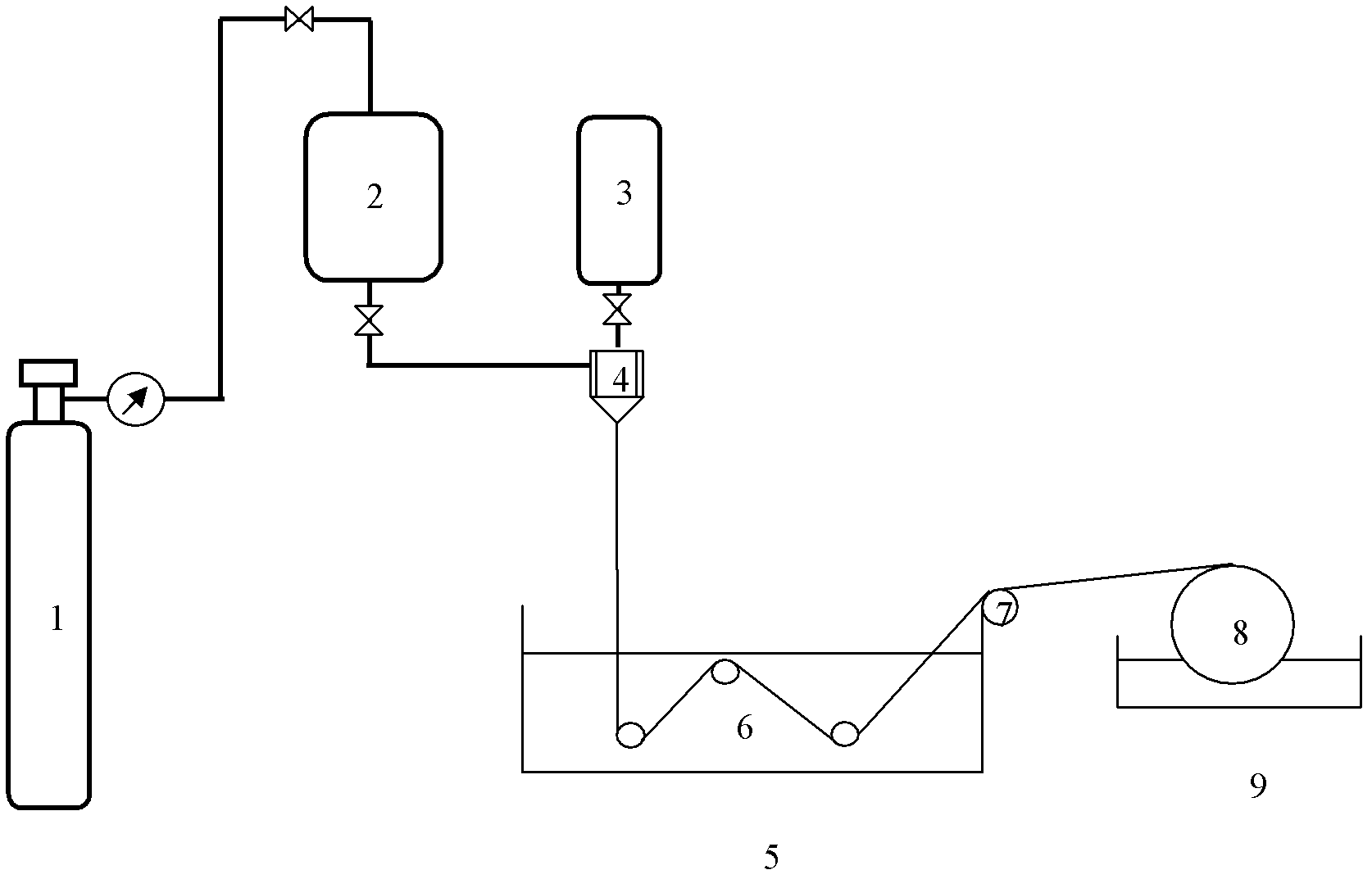

[0087] Example 1: Preparation of polyvinylidene fluoride hollow fiber microfiltration membrane of the present invention

[0088] The preparation steps are as follows:

[0089] A. Preparation of spinning solution

[0090] Dissolve 17 parts by weight of polyvinylidene fluoride, 3 parts by weight of ethylene-vinyl acetate copolymer, 4 parts by weight of polypyrrolidone, 5 parts by weight of polyethylene glycol, 6 parts by weight of polyvinyl alcohol, and 1 part by weight of lithium chloride in 40 parts by weight of In parts of dimethylacetamide and 24 parts by weight of dimethylformamide solvent, a spinning solution is obtained after filtering with a 100-mesh filter screen of aperture;

[0091] B. Preparation of core liquid and coagulation bath

[0092] Dissolving dimethylacetamide in water to obtain a core liquid with a concentration of 70% by weight;

[0093] Dimethylacetamide was dissolved in water to obtain a coagulation bath with a concentration of 20% by weight;

[0094...

Embodiment 2

[0102] Example 2: Preparation of polyvinylidene fluoride hollow fiber microfiltration membrane of the present invention

[0103] The preparation steps are as follows:

[0104] A. Preparation of spinning solution

[0105] Dissolve 16.5 parts by weight of polyvinylidene fluoride, 2 parts by weight of ethylene-vinyl acetate copolymer, 5 parts by weight of polypyrrolidone, 5 parts by weight of polyethylene glycol, 6 parts by weight of polyvinyl alcohol, and 1 part by weight of lithium chloride in 40 parts by weight In parts of dimethylacetamide and 24.5 parts by weight of dimethylformamide, a spinning solution is obtained after filtering with a 100-mesh filter screen of aperture;

[0106] B. Preparation of core liquid and coagulation bath

[0107] Dissolve dimethylacetamide in water to obtain a core liquid with a concentration of 40% by weight;

[0108] Dimethylacetamide was dissolved in water to obtain a coagulation bath with a concentration of 20% by weight;

[0109] C. Dry-...

Embodiment 3

[0117] Example 3: Preparation of polyvinylidene fluoride hollow fiber microfiltration membrane of the present invention

[0118] The preparation steps are as follows:

[0119] A. Preparation of spinning solution

[0120] Dissolve 16.5 parts by weight of polyvinylidene fluoride, 3.5 parts by weight of ethylene-vinyl acetate copolymer, 5 parts by weight of polypyrrolidone, 4 parts by weight of polyethylene glycol, 6 parts by weight of polyvinyl alcohol, and 1.5 parts by weight of lithium chloride in 40 parts by weight In parts of dimethylacetamide and 24 parts by weight of nitrogen methyl pyrrolidone, a spinning solution is obtained after filtering with a 100-mesh filter screen with an aperture;

[0121] B. Preparation of core liquid and coagulation bath

[0122] Dissolve dimethylacetamide in water to obtain a core liquid with a concentration of 40% by weight;

[0123] Dimethylacetamide was dissolved in water to obtain a coagulation bath with a concentration of 20% by weight;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com