Hydrophilic modification method of PVDF multihole film

A hydrophilic modification, porous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of strong hydrophobicity, easy pollution, low water flux, etc. , good compatibility, strong hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

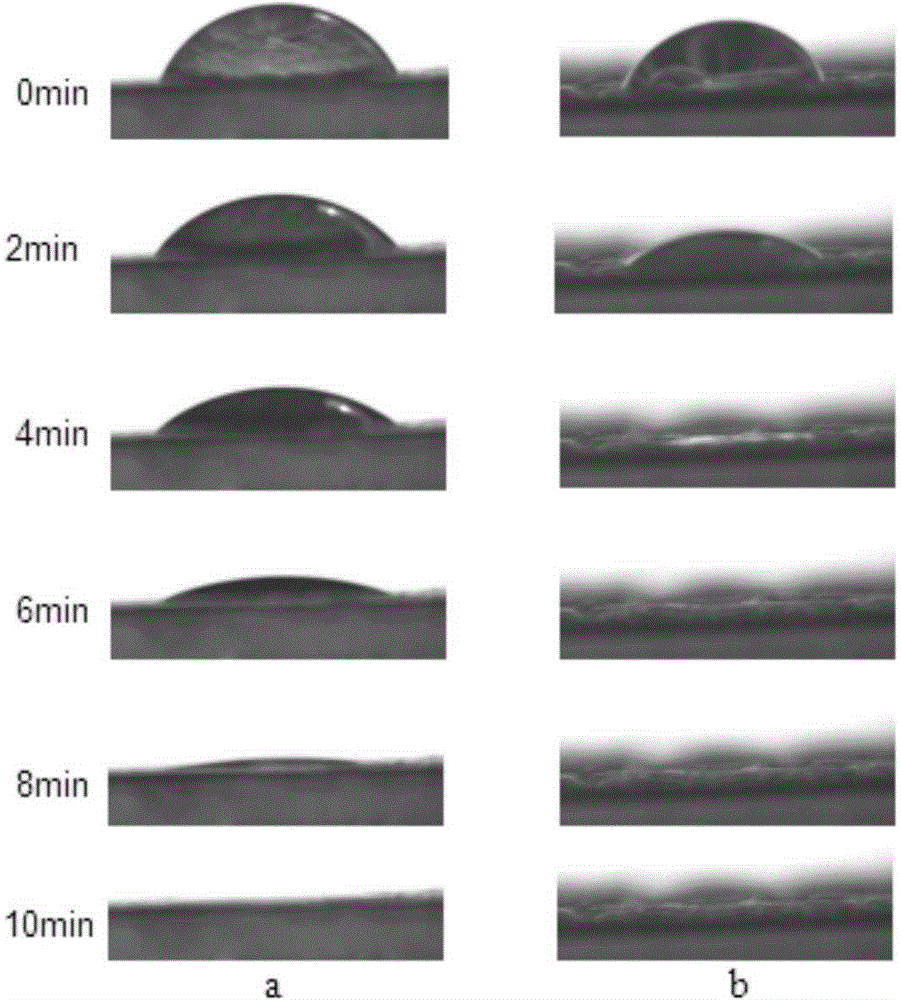

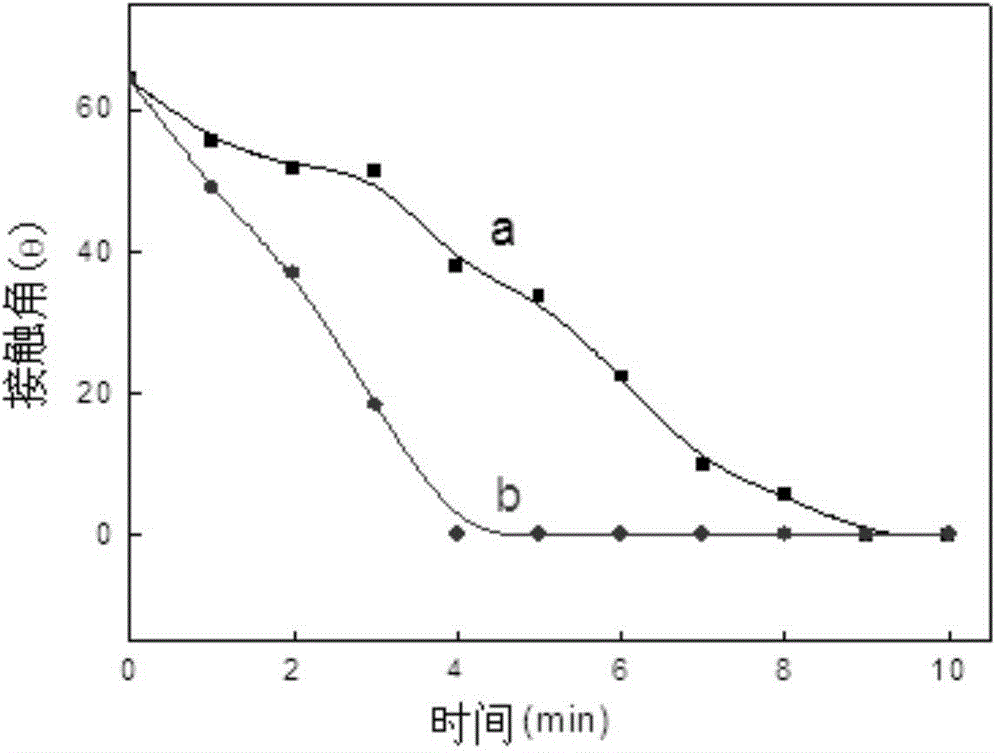

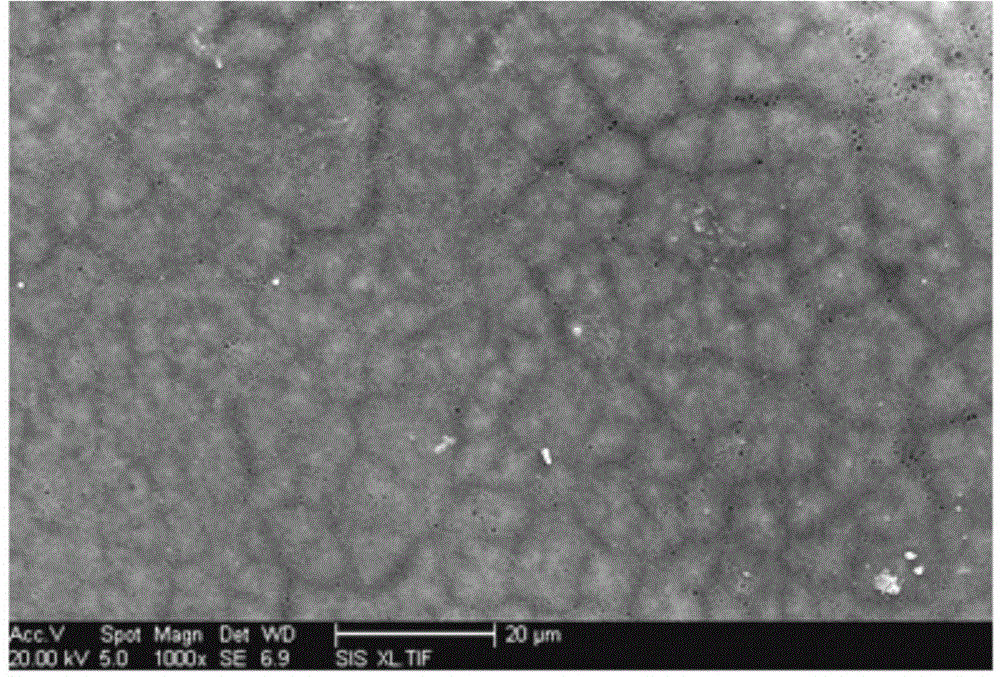

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the hydrophilic modification method of the present embodiment PVDF porous film is as follows:

[0027] 1. Put 2-acrylamide-2-methylpropanesulfonic acid in a beaker, add dimethylformamide, and stir to obtain 2-acrylamide-2-methylpropanesulfonic acid with a mass concentration of 20-40%. solution;

[0028] 2. Add methyl methacrylate to the solution obtained in step 1 according to the ratio of 2-acrylamido-2-methylpropanesulfonic acid to methyl methacrylate, and then add Azobisisobutyronitrile, the amount of azobisisobutyronitrile added is 5‰-1% of the total mass of 2-acrylamide-2-methylpropanesulfonic acid and methyl methacrylate to obtain a reaction system;

[0029] 3. Heat the reaction system to 65-75°C, then stir for 5 hours while heating at 65-75°C, cool to room temperature, and distill under reduced pressure to obtain a polymer solution after vacuum distillation;

[0030] 4. Pour the polymer solution after vacuum distillation into a precipit...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of 2-acrylamide-2-methylpropanesulfonic acid in the solution described in step 1 is 25%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the addition of azobisisobutyronitrile described in step two is 2-acrylamide-2-methylpropanesulfonic acid and methane 0.5% of the total mass of methyl acrylate. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com