Hydrophilic modifying method and heat exchanger treated with it

一种亲水改性、热交换器的技术,应用在热交换设备、蓄热式换热器、传热改性等方向,能够解决表面很难亲水性、接触到恶劣条件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-21

[0080] (Preparation of hydrophilic modifier)

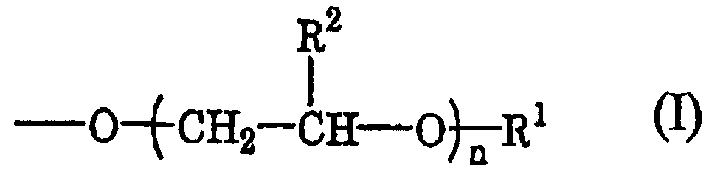

[0081] According to the formula shown in Table 1, the hydrophilic modifier with each concentration (mass%) given in Table 1 is obtained by combining modified polyvinyl alcohol powder, phosphorus compound salt, boron compound salt, and hydrophilic It is prepared by blending organic compounds, crosslinking agents, etc. PVA-1 [degree of saponification 99%; number average molecular weight 50,000] is used as polyvinyl alcohol which does not have any group related to the above-mentioned general formula (I). Used as the modified polyvinyl alcohol are PVA-2, PVA-3 and PVA-4 [n in the above general formula (I) are 10, 10 and 20, respectively; the groups represented by the structural formula (I), respectively It accounts for 5 mol%, 1 mol% and 1 mol% relative to the hydroxyl and acetoxy groups in the molecule; the saponification degree is 99% and the number average molecular weight is 50,000, in each case]. The carboxylic acid-modified polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com