Microwave preparation method of smooth type quaternization block organosilicon polymer

A silicone, quaternization technology, applied in the direction of fiber type, improved hand fiber, textile and papermaking, etc., can solve the problems of difficult to repair and over-dye dyed fabrics, easy yellowing of fabrics, poor hydrophilicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

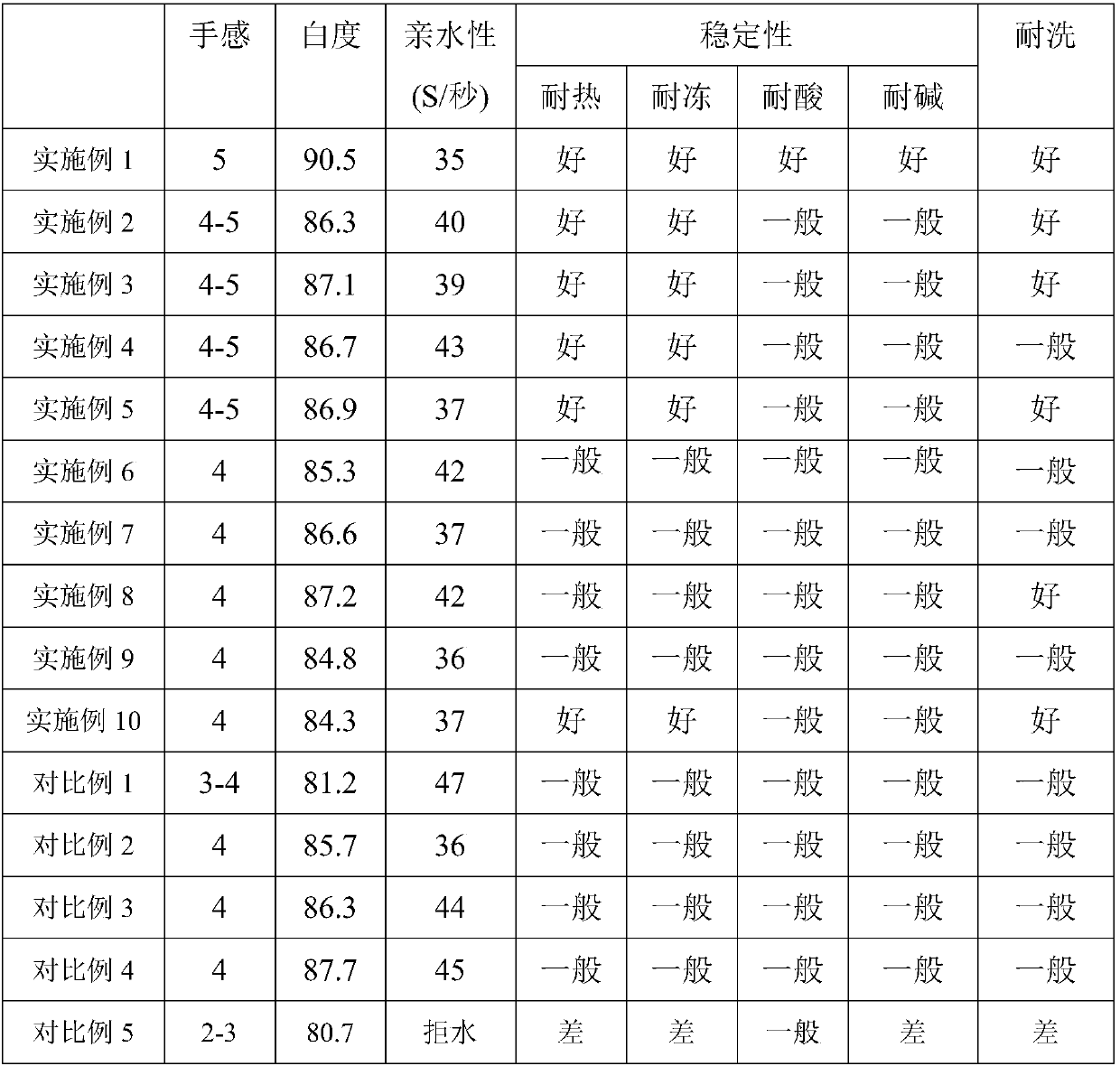

Examples

preparation example Construction

[0029] The invention provides a microwave preparation method for smooth quaternized block organosilicon polymer, which is characterized in that it comprises the following steps:

[0030] (1) Add allyl epoxy polyether and silicone oil to the reactor, mix them evenly and put them under microwave irradiation with a power of 50-600W, feed nitrogen gas, heat up to 80-100°C, add platinum catalyst, and keep warm Reaction 30-60min, obtain terminal epoxy silicone oil; The mol ratio of described silicone oil and described allyl epoxy polyether is 1: (1-1.2); The total of described allyl epoxy polyether and described silicone oil The weight ratio of the amount to the platinum catalyst is 1:(0.5×10 -5 -1×10 -5 ); the silicone oil includes one or more of terminal hydrogen-containing silicone oil and amino silicone oil;

[0031](2) Add the epoxy-terminated silicone oil, polyether amine, and organic solvent obtained in step (1) to the reactor, mix well and place it under microwave irradiat...

Embodiment 1

[0066] The microwave preparation method of the smooth type quaternized block organosilicon polymer comprises the following steps:

[0067] (1) Add allyl epoxy polyether and silicone oil to the reactor, mix them evenly, place them under microwave irradiation, the power is 300W, feed nitrogen gas, heat up to 90°C, add platinum catalyst, and keep the temperature for 50min to obtain Terminal epoxy silicone oil;

[0068] (2) Add epoxy-terminated silicone oil, polyether amine, and organic solvent obtained in step (1) into the reactor, mix well and place under microwave irradiation with a power of 300W, feed nitrogen gas, heat up to 80°C, and keep warm React for 3 hours to obtain the block organosilicon intermediate A;

[0069] (3) Add a chain extender to step (2), and react at 80°C for 60 minutes to continue the chain extension of the block organosilicon intermediate A, and then use glacial acetic acid to adjust the pH value of the system to neutral to obtain a smooth quaternary am...

Embodiment 2

[0080] The microwave preparation method of the smooth type quaternized block organosilicon polymer comprises the following steps:

[0081] (1) Add allyl epoxy polyether and silicone oil to the reactor, mix them evenly, place them under microwave irradiation, the power is 300W, feed nitrogen gas, heat up to 90°C, add platinum catalyst, and keep the temperature for 50min to obtain Terminal epoxy silicone oil;

[0082] (2) Add epoxy-terminated silicone oil, polyether amine, and organic solvent obtained in step (1) into the reactor, mix well and place under microwave irradiation with a power of 300W, feed nitrogen gas, heat up to 80°C, and keep warm React for 3 hours to obtain the block organosilicon intermediate A;

[0083] (3) Add a chain extender to step (2), and react at 80°C for 60 minutes to continue the chain extension of the block organosilicon intermediate A, and then use glacial acetic acid to adjust the pH value of the system to neutral to obtain a smooth quaternary am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com