Microcapsule with integrated ultraviolet shielding function and preparation method thereof

A microcapsule and external shielding technology is applied in the field of microcapsules with integrated ultraviolet shielding function and the field of preparation thereof, which can solve problems such as the decline of anti-ultraviolet performance, and achieve the effect of excellent anti-ultraviolet effect and promotion of ultraviolet absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

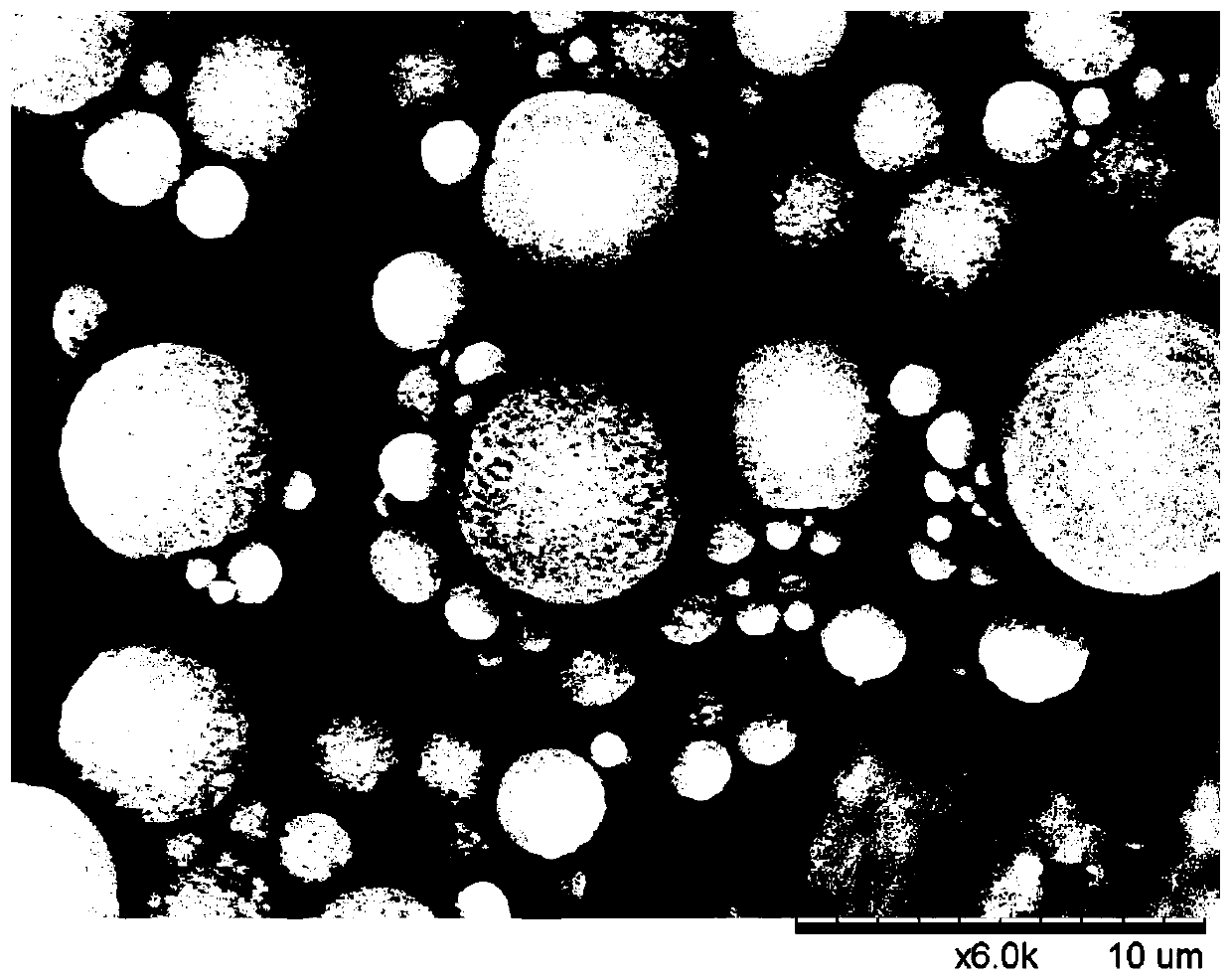

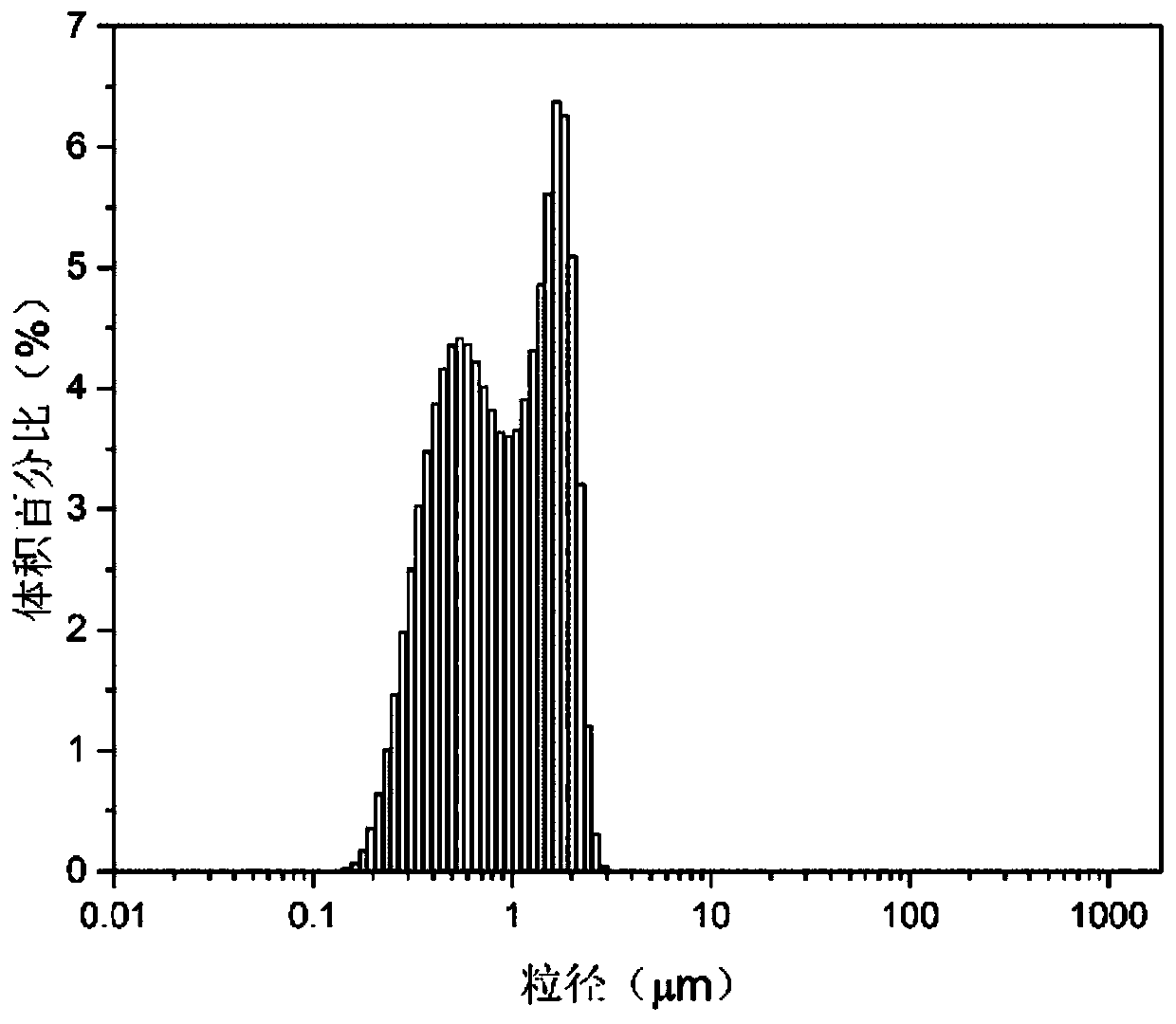

Embodiment 1

[0038] Step 1: Weigh 6g of methyl methacrylate, 1g of methacrylic acid, 3g of pentaerythritol tetraacrylate, 0.3g of 2,2-azobisisobutyronitrile and 10g of 2-hydroxyl-4-methane Oxybenzophenone was mixed uniformly at 70°C to form an oil phase, and 1g of sodium lignosulfonate was weighed and dissolved in water to form a uniform water phase. Under high-speed shear (shear speed 9000rpm), the above-mentioned oil phase is slowly added to the water phase, and the high-speed shear emulsification is performed for 10 minutes, and the resulting oil-in-water emulsion is transferred to a three-necked flask, under nitrogen protection and reflux condensation conditions The temperature was raised to 85° C., the polymerization was continued for 3 hours, and then washed with ethanol and water and suction filtered to obtain a polyacrylate-coated UV-resistant microcapsule filter cake.

[0039] Step 2: Disperse the microcapsule filter cake in step 1 in deionized water to obtain a microcapsule dispe...

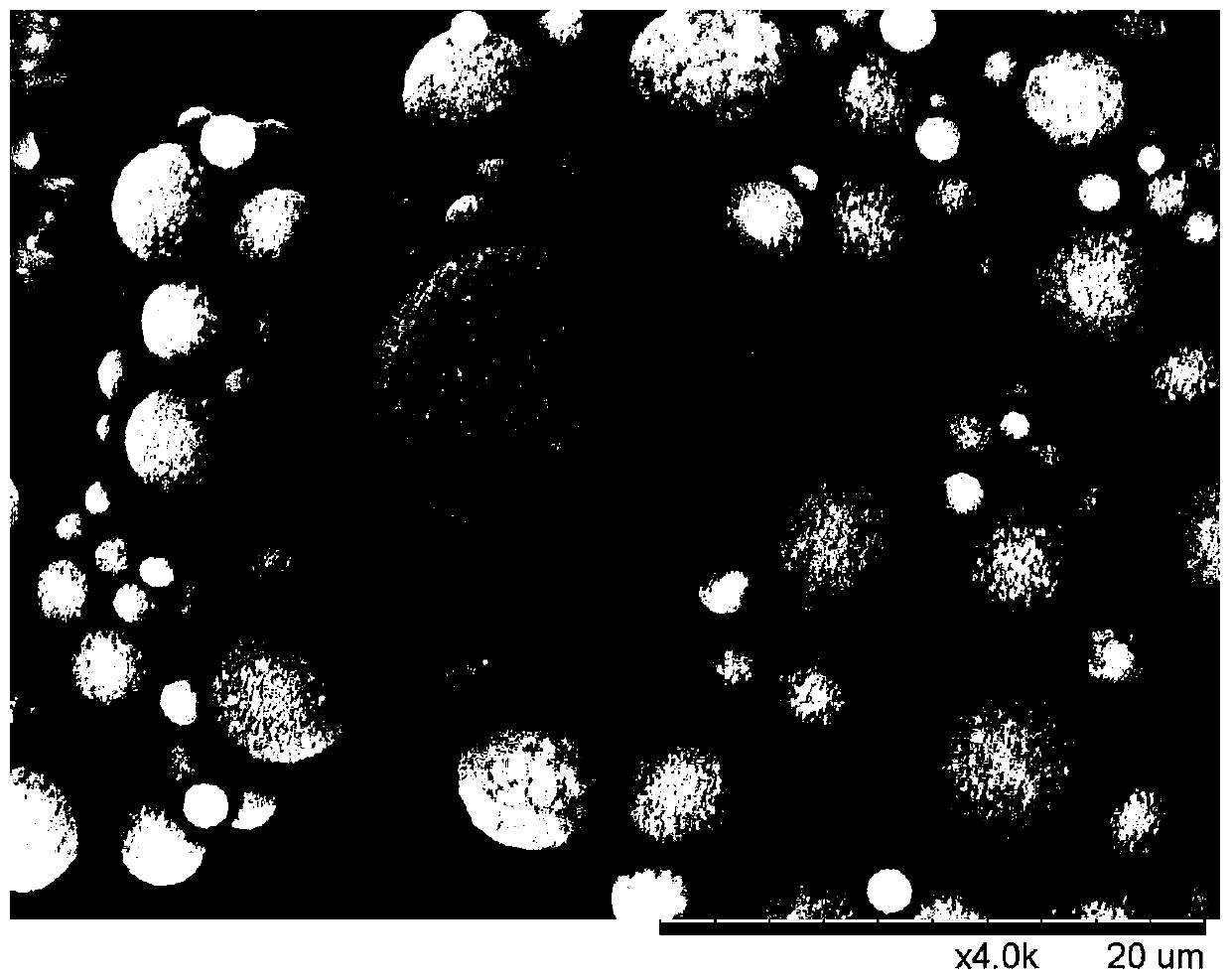

Embodiment 2

[0043] Step 1: Weigh 6g of methyl methacrylate, 1g of methacrylic acid, 3g of pentaerythritol tetraacrylate, 0.3g of 2,2-azobisisobutyronitrile and 20g of 2,2'-dihydroxy - 4-methoxybenzophenone, mixed uniformly at 70°C to form an oil phase, weighed 2g of sodium lignosulfonate and dissolved in water to form a uniform water phase. Under high-speed shear (shear speed 9000rpm), the above-mentioned oil phase is slowly added to the water phase, and the high-speed shear emulsification is performed for 10 minutes, and the resulting oil-in-water emulsion is transferred to a three-necked flask, under nitrogen protection and reflux condensation conditions The temperature was raised to 85° C., and the polymerization was continued for 5 hours, followed by washing with ethanol and water and suction filtration to obtain a polyacrylate-coated UV-resistant microcapsule filter cake.

[0044] Step 2: Disperse the microcapsule filter cake in step 1 in deionized water to obtain a microcapsule disp...

Embodiment 3

[0048] Step 1: Weigh 6g of methyl methacrylate, 1g of methacrylic acid, 3g of pentaerythritol tetraacrylate, 0.3g of 2,2-azobisisobutyronitrile and 20g of 2-hydroxyl-4-n- Octylbenzophenone was mixed uniformly at 50°C to form an oil phase, and 2g of sodium lignosulfonate was weighed and dissolved in water to form a uniform water phase. Under high-speed shear (shear speed 9000rpm), the above-mentioned oil phase is slowly added to the water phase, and the high-speed shear emulsification is performed for 10 minutes, and the resulting oil-in-water emulsion is transferred to a three-necked flask, under nitrogen protection and reflux condensation conditions The temperature was raised to 85° C., the polymerization was continued for 4 hours, and then washed with ethanol and water and suction filtered to obtain a polyacrylate-coated UV-resistant microcapsule filter cake.

[0049] Step 2: Disperse the microcapsule filter cake in step 1 in deionized water to obtain a microcapsule dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com