Ultraviolet shielding transparent plastic packaging film

A transparent plastic and external shielding technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems affecting the gas barrier properties of films, chemical reactions of products, eye and skin damage, etc., to achieve excellent ultraviolet shielding effect and prevent Agglomerates and enhances the effect of UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

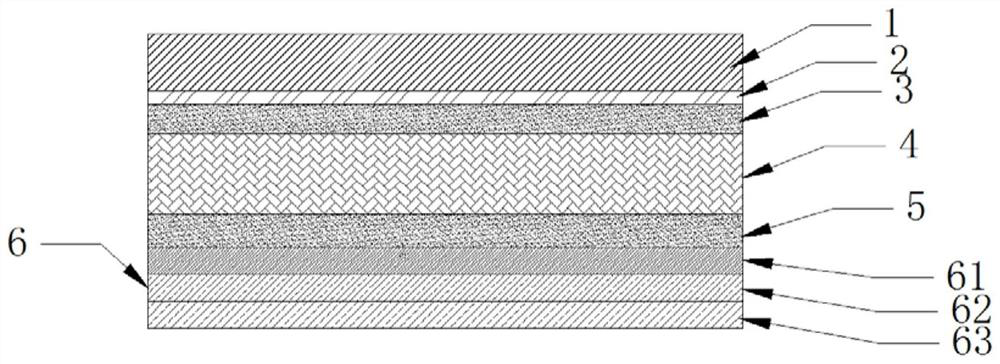

[0019] An ultraviolet shielding transparent plastic packaging film, the packaging film is a polyester film (PET) 1, an ink layer 2, a first ultraviolet shielding adhesive layer 3, a barrier layer 4, and a second ultraviolet shielding adhesive layer from outside to inside 5 and a heat-sealing layer 6; the thickness of the ultraviolet shielding transparent plastic packaging film is 107 μm, wherein the thickness of the polyester film layer is 30 μm, the thickness of the ink layer is 2 μm, and the thickness of the first ultraviolet shielding adhesive layer is 5 μm. The thickness of the layer is 5 μm, the thickness of the second ultraviolet shielding adhesive layer is 10 μm, and the thickness of the heat-sealing layer is 55 μm;

[0020] Add methoxycinnamate, octocrylene and hydrophobically modified zinc oxide ultraviolet shielding agent to the first ultraviolet shielding layer and the second ultraviolet shielding layer.

[0021] The first ultraviolet shielding adhesive layer or the...

Embodiment 2

[0026] An ultraviolet shielding transparent plastic packaging film, the packaging film is a polyester film, an ink layer, a first ultraviolet shielding adhesive layer, a barrier layer, a second ultraviolet shielding adhesive layer and a heat seal layer from outside to inside; The thickness of the UV shielding transparent plastic packaging film is 182 μm, the thickness of the polyester film layer is 60 μm, the thickness of the ink layer is 2 μm, the thickness of the first UV shielding adhesive layer is 10 μm, the thickness of the barrier layer is 15 μm, the second UV The thickness of the shielding adhesive layer is 15 μm, and the thickness of the heat-sealing layer is 80 μm;

[0027] Add methoxycinnamate, octocrylene and hydrophobically modified zinc oxide ultraviolet shielding agent to the first ultraviolet shielding layer and the second ultraviolet shielding layer.

[0028] The first ultraviolet shielding adhesive layer or the second ultraviolet shielding layer, according to ...

Embodiment 3

[0033] An ultraviolet shielding transparent plastic packaging film, the packaging film is a polyester film, an ink layer, a first ultraviolet shielding adhesive layer, a barrier layer, a second ultraviolet shielding adhesive layer and a heat seal layer from outside to inside; The thickness of the UV shielding transparent plastic packaging film is 248 μm, the thickness of the polyester film layer is 80 μm, the thickness of the ink layer is 3 μm, the thickness of the first UV shielding adhesive layer is 15 μm, the thickness of the barrier layer is 30 μm, and the thickness of the second UV The thickness of the shielding adhesive layer is 30 μm, and the thickness of the heat-sealing layer is 90 μm;

[0034] Add methoxycinnamate, octocrylene and hydrophobically modified zinc oxide ultraviolet shielding agent to the first ultraviolet shielding layer and the second ultraviolet shielding layer.

[0035] The first ultraviolet shielding adhesive layer and the second ultraviolet shieldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com